当前位置:上海萨帛机电控制系统有限公司>> MG175-G60-AQ1EGG,EagleBurgmann机械密封进口优惠销售

快速报价以下EagleBurgmann列表型号!若您的EagleBurgmann型号与以下型号类似,或者品牌一样,我们都可以为您找到,约1-2个工作日反馈报价!

基于我们与EagleBurgmann厂家备件部门的长期通力合作,以更好的采购、更精准的货期、更专业的服务态度为您全天候服务!

本公司是欧洲工控产品供应商,直接源头采购欧洲产地工业备件,欧洲工控产品*品质欧洲工控产品进口原装欧洲工控产品精确货期。

上海萨帛机电设备有限公司,价格优势!

----------------------------------------------------------

- 销售工程师:何工 -

- -

- :(直线) -

- -

- :henry@sahbore.com或者 -

-----------------------------------------------------------

地址:上海市嘉定区福海路777号嘉福汇商务广场1号楼604-605室

公司:www.sahbore。。com

询价请提供(品牌+型号+数量+公司全称/)或原产品的现场图片信息。我们会尽快做出回复 。

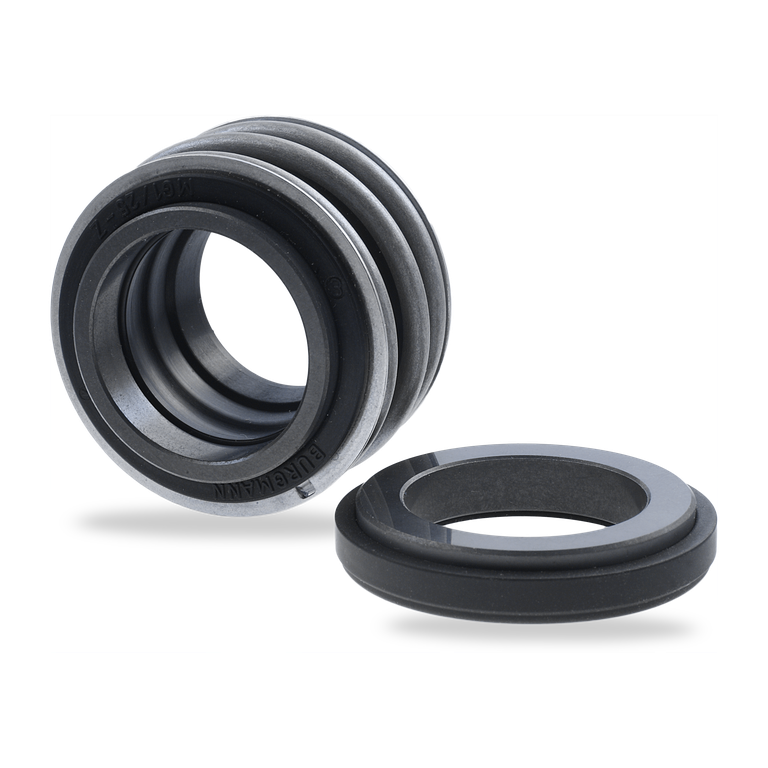

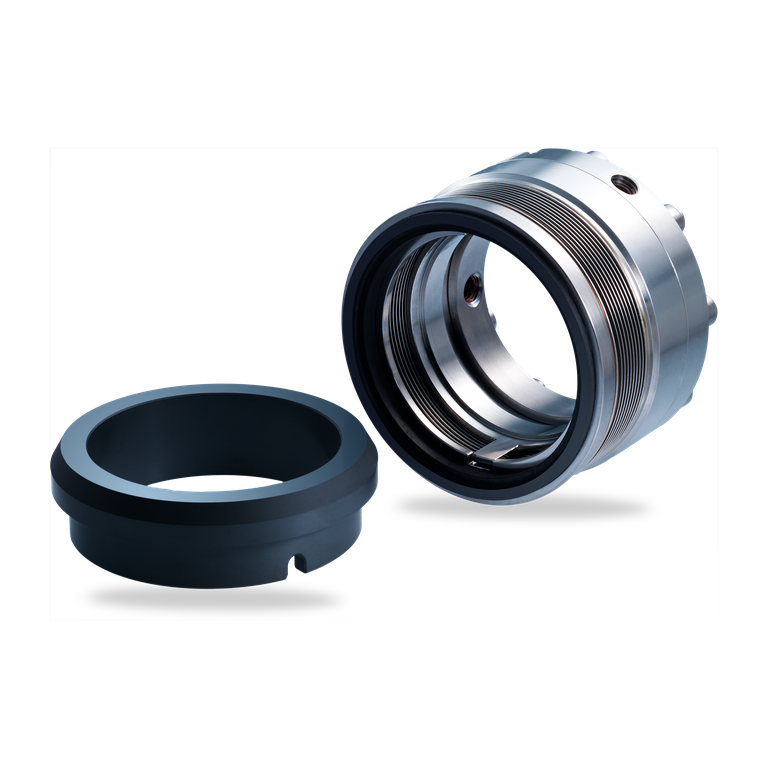

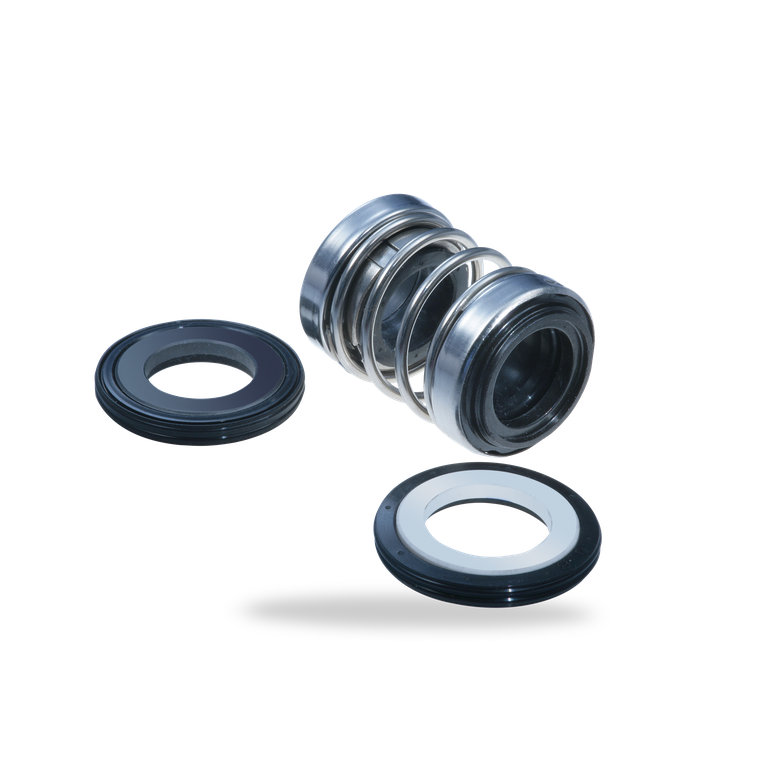

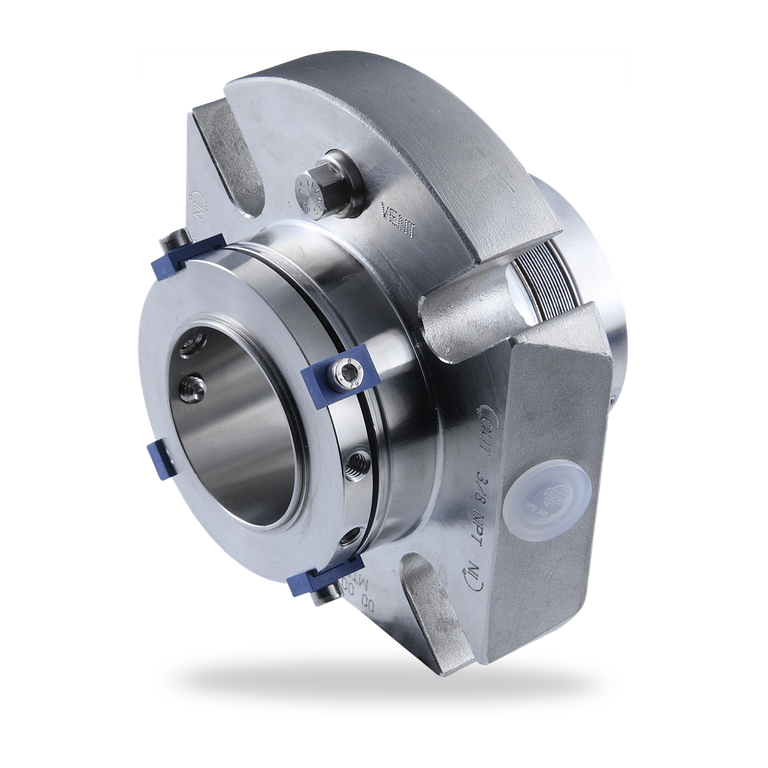

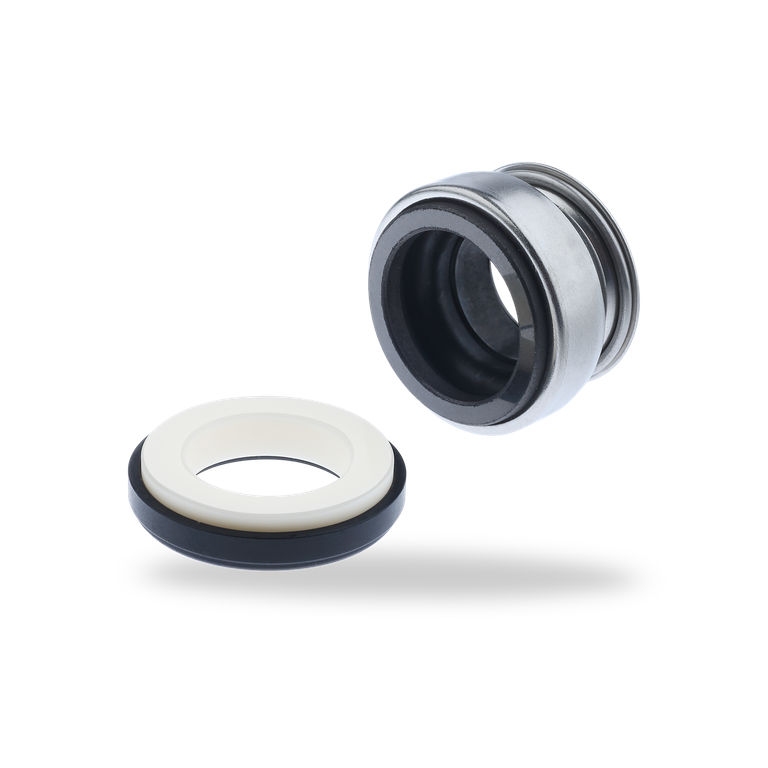

优价销售:EagleBurgmann MG13/48-G4,ID-NR.036208002 机械密封

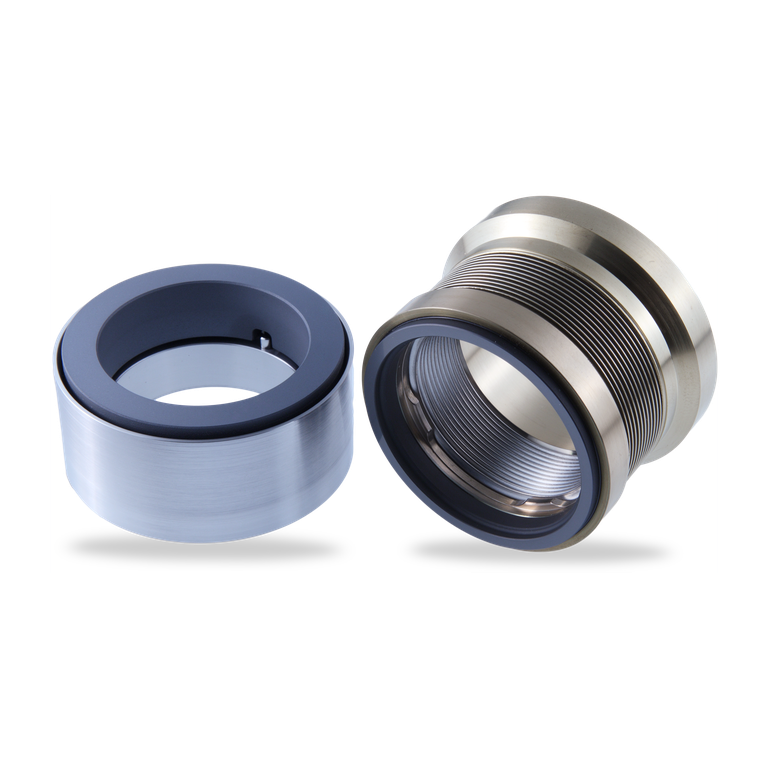

EagleBurgmann 219,5 X 6,99 TTV 104684375 O型圈组件

EagleBurgmann 246,5 X 6,99 TTV 115805375 O型圈组件

EagleBurgmann 312 X 3,53 V 250299350 O型圈组件

EagleBurgmann 291,69 X 3,53 V 101872350 O型圈组件

EagleBurgmann 222 X 6,99V 104692350 O型圈组件

EagleBurgmann 240,67 X 6,99 V 104731350 O型圈组件

EagleBurgmann 202,57 X 5,33 V 103654350 O型圈组件

EagleBurgmann 309,5 X 6,99 T 115847370 O型圈组件

EagleBurgmann 199,7 X 5,33 FEP 103646380 O型圈组件

EagleBurgmann 20*10m/Rolle,Gemass Figur Anhaenge 四氟带

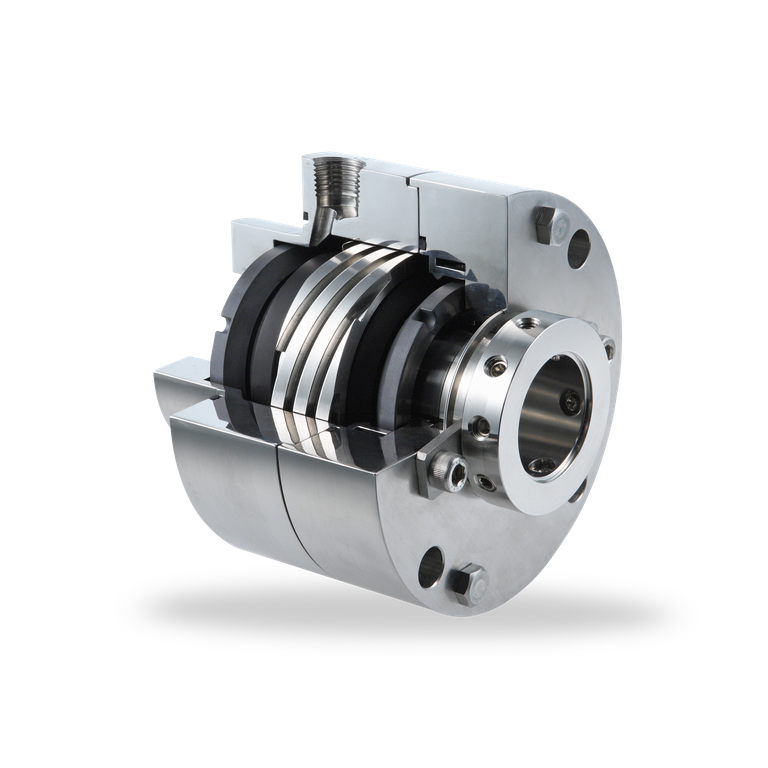

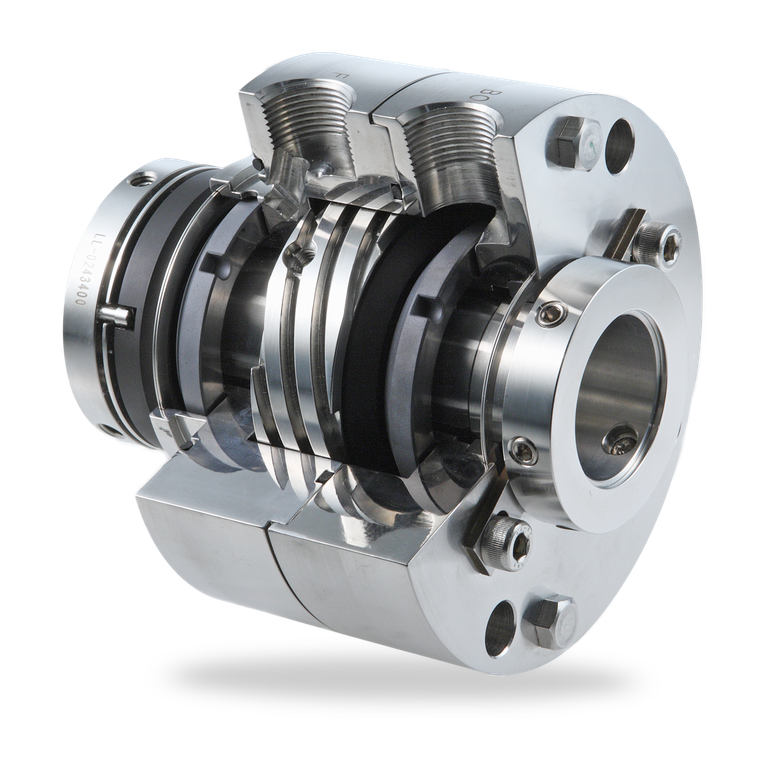

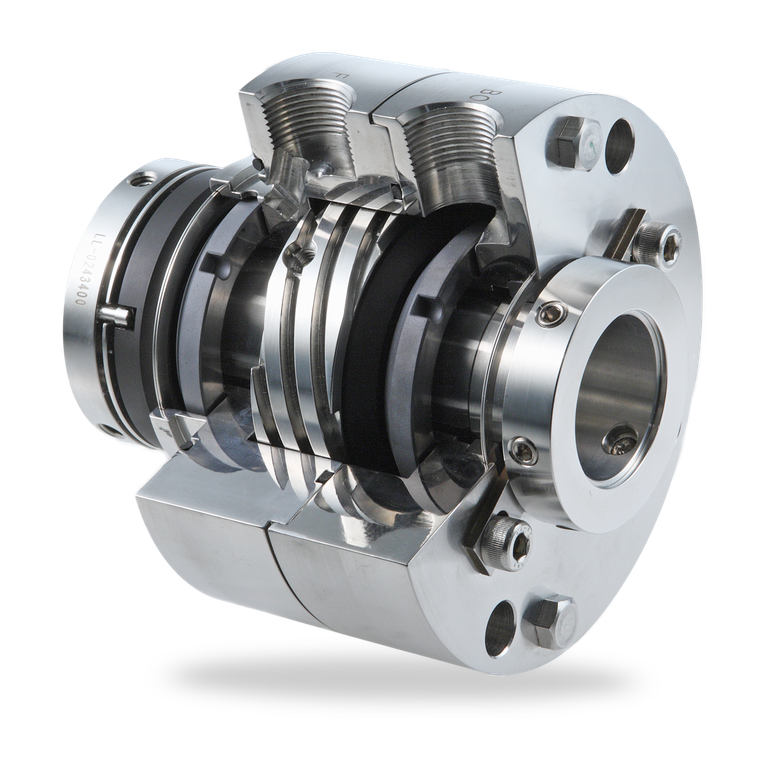

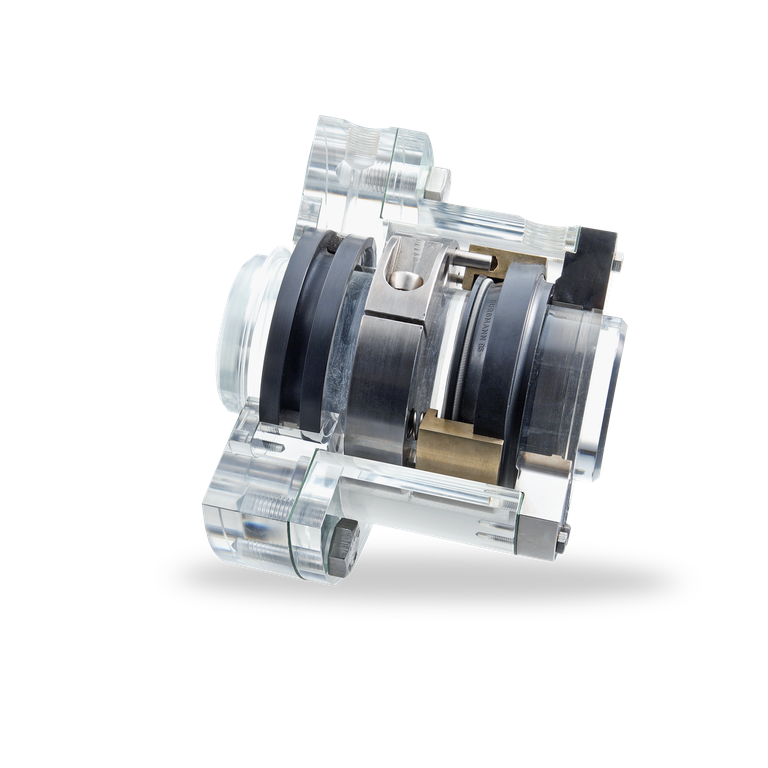

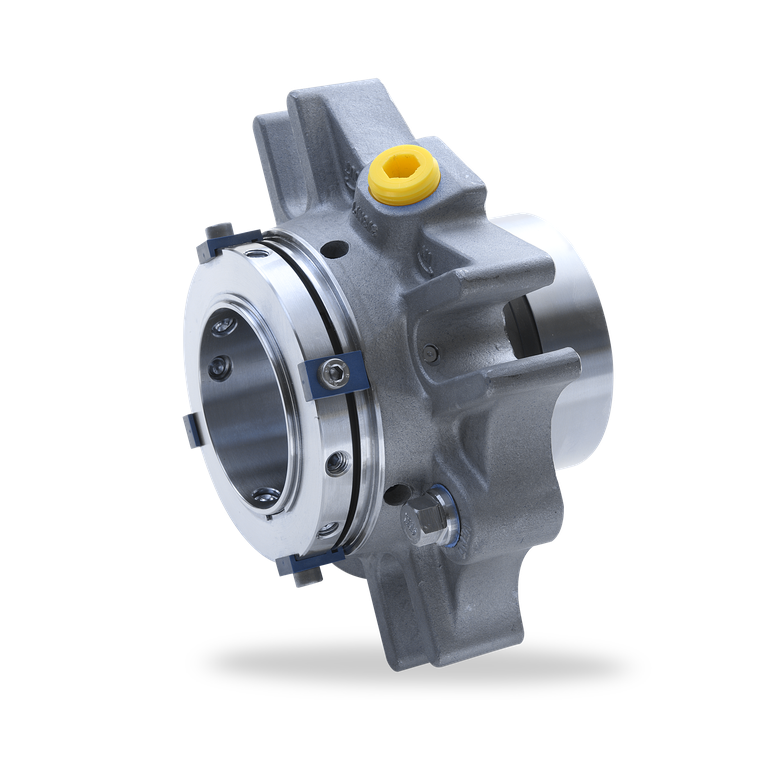

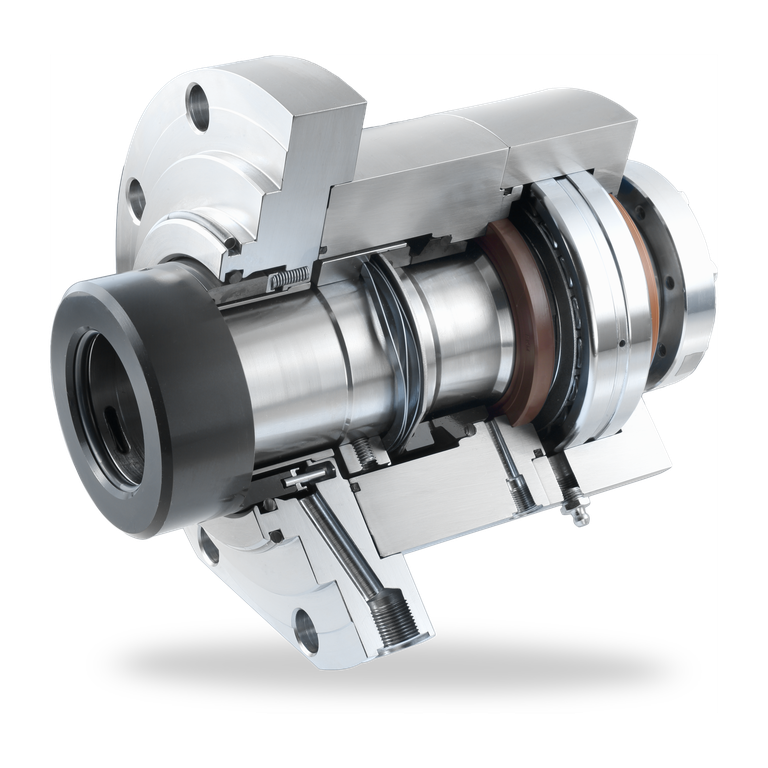

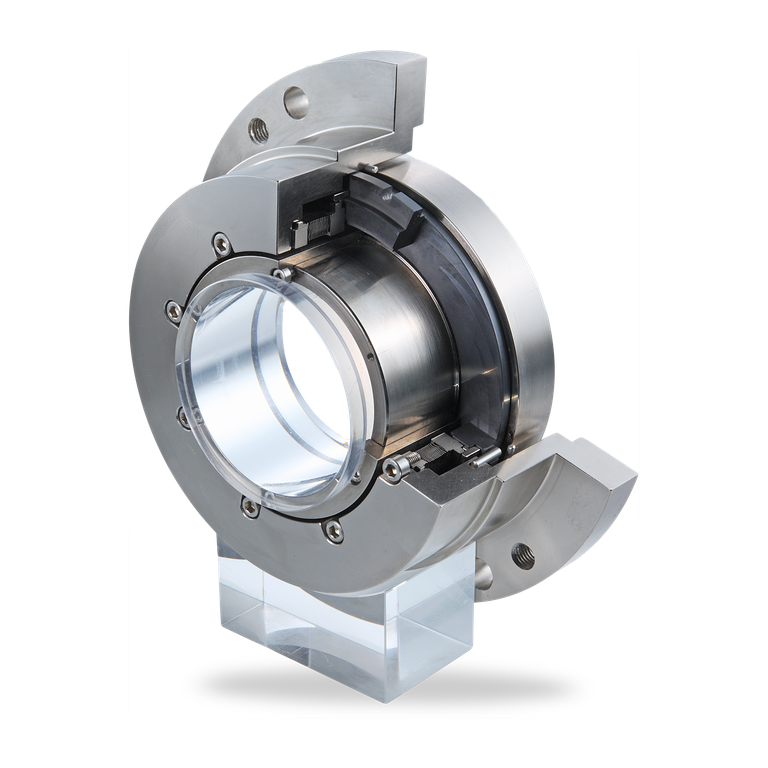

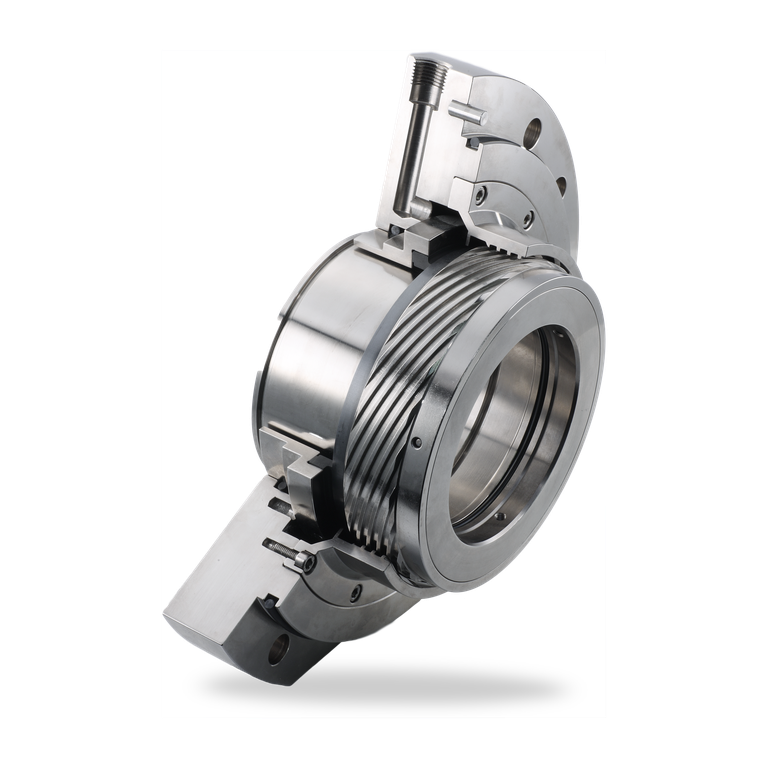

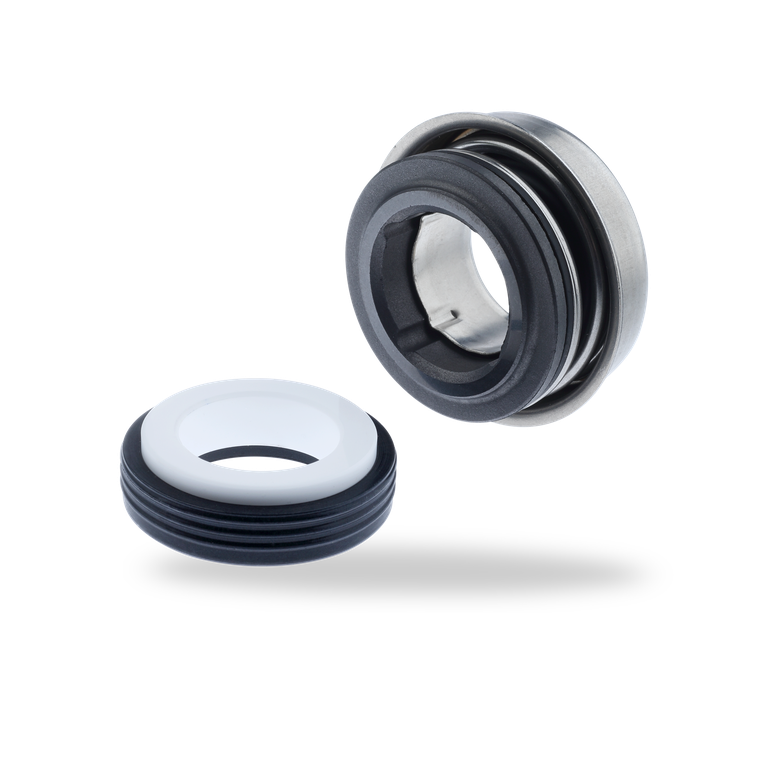

EagleBurgmann MG1/75-G60-AQ1EGG for pump type NPG300/400-132/4 机械密封

EagleBurgmann MG1/75-G60-AQ1EGG for pump type NPG300/400-132/4 机械密封

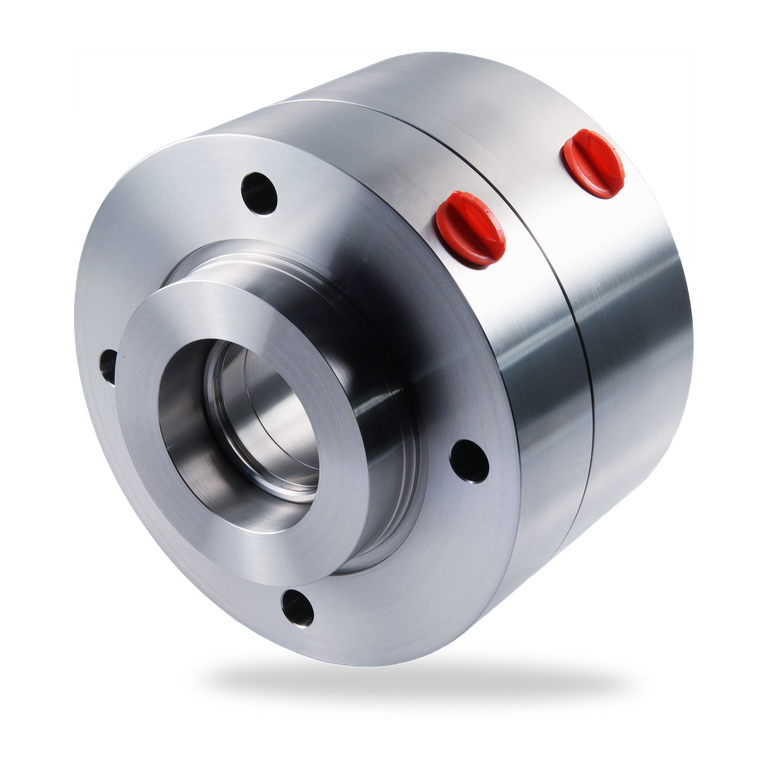

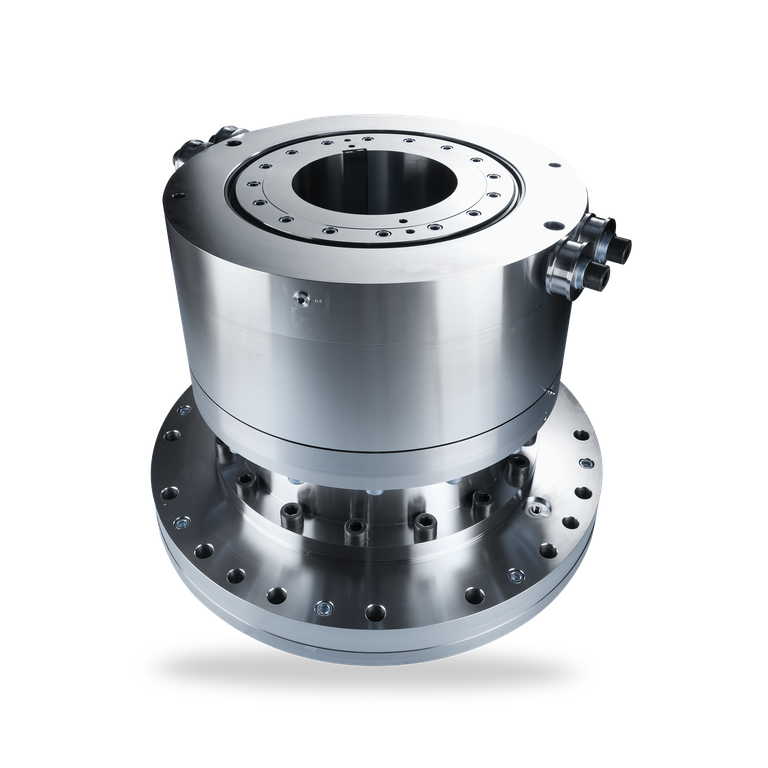

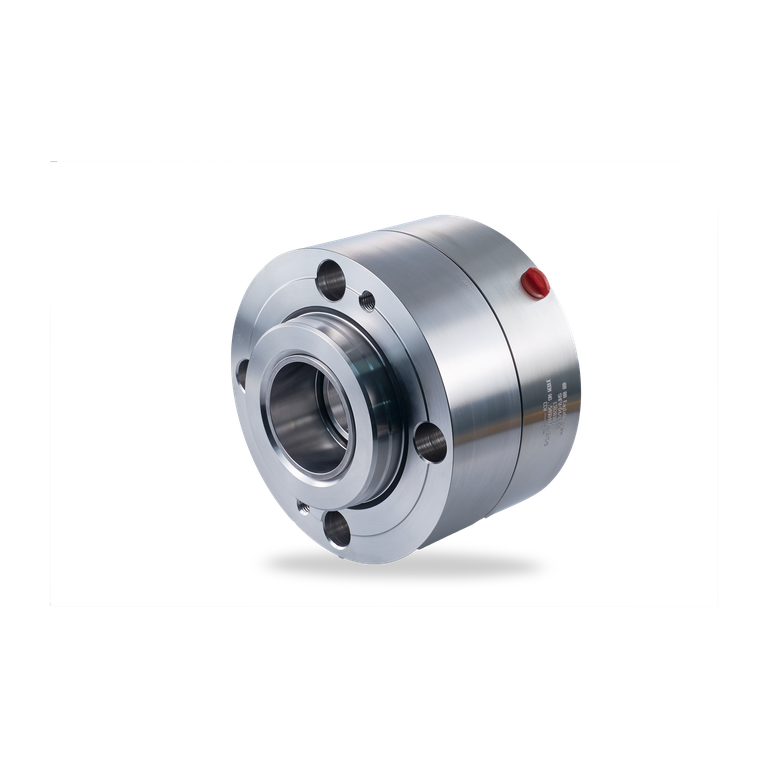

EagleBurgmann MAK66S4-110-6-00, ID-NR.038445001 磁性联轴器

EagleBurgmann SPS2000/A012-00 位移传感器

EagleBurgmann SPU2040/A020-00 密封泵

EagleBurgmann SPU2040/A020-00 密封泵

EagleBurgmann MG1/75-G60-AQ1EGG for pump type NPG300/400-132/4 机械密封

EagleBurgmann MG1/75-G60-AQ1EGG for pump type NPG300/400-132/4 机械密封

Industrial sector

Industrial sector Chemical industry Food processing industry Lime, cement and gypsum industry Machinery and plant building Metal production and processing Mining industry Oil and gas industry Petrochemical industry Power plant technology Pulp and paper industry Refining technology Shipbuilding Waste incineration and removal industry Water and waste water technology

Index

Index Espey WD100 Espey WD200 Espey WD200/500 Espey WD500 Espey WDB200 Espey WDK-BHS Espey WDKS-Eco Espey WDMS500 Espey WKA3 Espey WKA250ND Espey WKA300 Espey WKA400HD Espey WKA700 Espey WKA802HD Espey WKA1100HP

Search

Espey WKA3

Espey WKA3

Espey WDB200

Espey WDB200

Espey WD100

Espey WD100

Espey WD200

Espey WD200

Espey WDK-BHS

Espey WDK-BHS

Espey WDKS-Eco

Espey WDKS-Eco

Espey WD500

Espey WD500

Espey WD200/500

Espey WD200/500

Espey WDMS500

Espey WDMS500

Espey WKA300

Espey WKA300

Espey WKA250ND

Espey WKA250ND

Espey WKA400HD

Espey WKA400HD

Espey WKA700

Espey WKA700

Espey WKA802HD

Espey WKA802HD

Espey WKA1100HP

Espey WKA1100HP

H75VA4-S

H75VA4-S

MBS682

MBS682

WEF6

WEF6

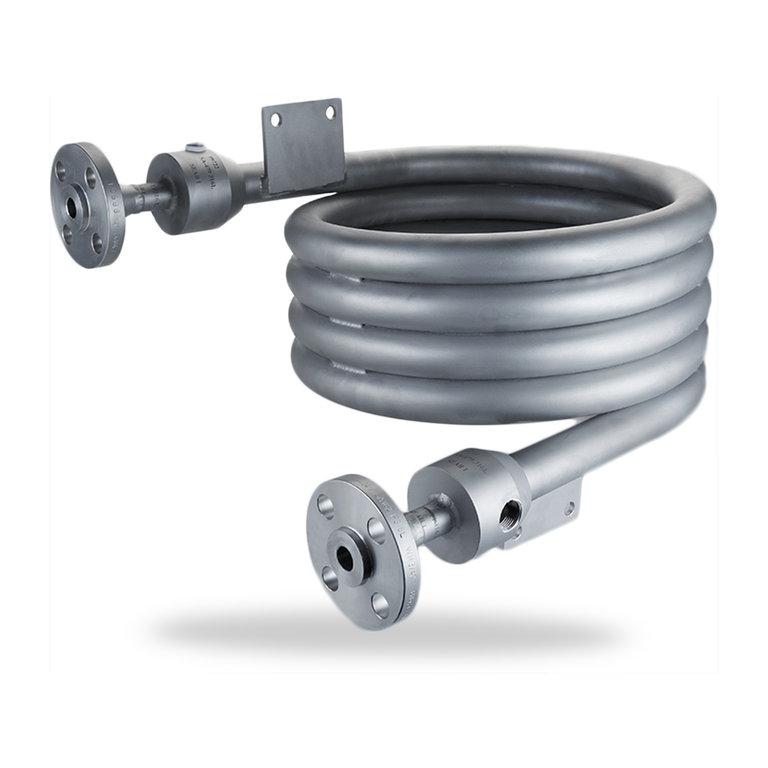

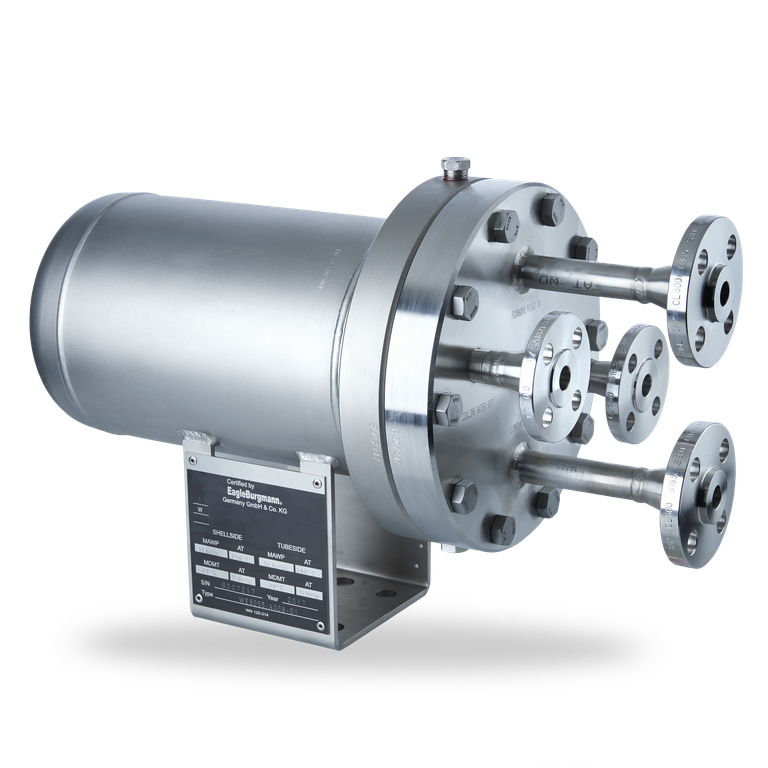

Water coolerHeat exchangers of the WEF6000-A4 range are used to cool process/barrier fluids in seal supply circuits. WEF6000-A4 heat exchangers are fully compliant with API 682 4th edition regulations. The process/barrier medium is directed through the tube, and the cooling medium is directed through the shell.

Venting and draining of the process/barrier medium side as well as the cooling water side is ensured. In addition, the heat exchangers can also be combined with a temperature instrument in the supply line to the mechanical seal (optional in accordance with API 682 4th edition).

SPT6

SPT6

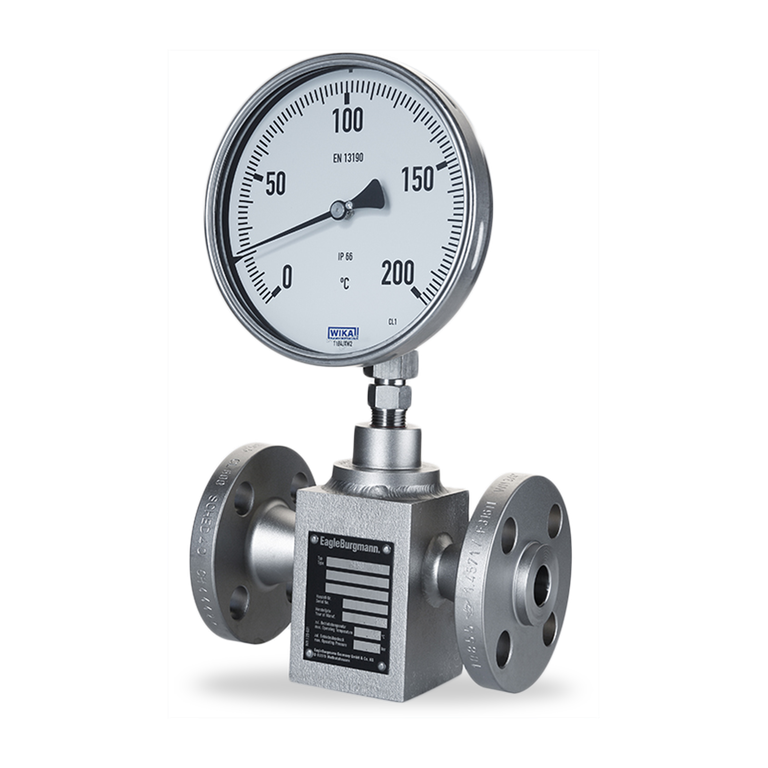

Temperature indicatorThe measuring unit of the SPT6000-A4 range is used to visually monitor the operating temperature.

The measuring unit consists of a bi-metallic temperature gauge (NG100) with protective sleeve installed in a measuring block incl. drain connection.

ZYA6

ZYA6

Cyclone separatorThe ZY6000-A4 range is available in three versions:

ZYA6000-A4

Cyclone separator for high flow rates and high pressures.

ZYB6000-A4

Cyclone separator for high flow rates and high pressures; 100 % X-ray capability.

ZYC6000-A4

Cast version, block-type design with integral flanges.

SPX6

SPX6

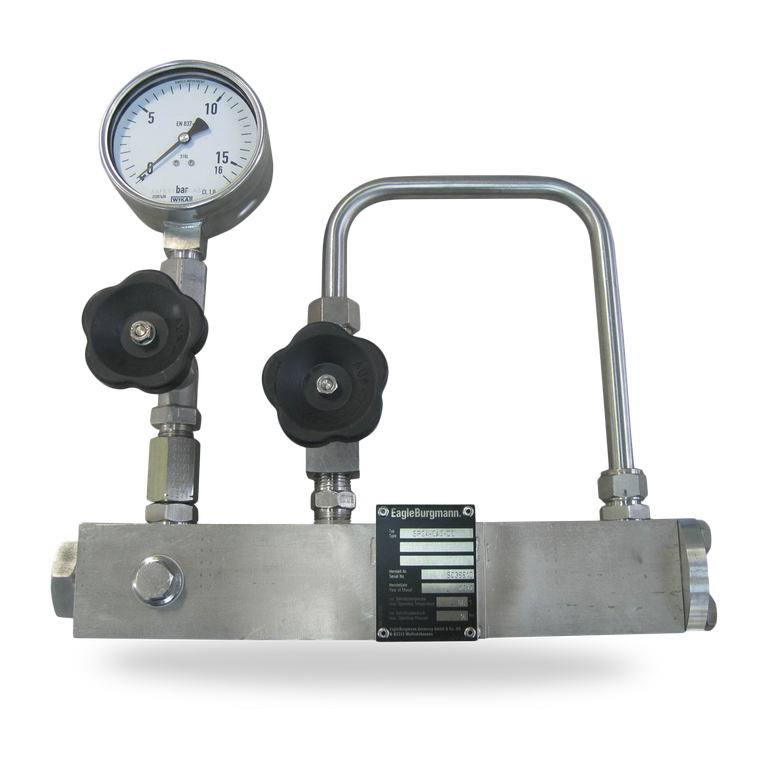

Flush unitThe EagleBurgmann flush unit of the SPX6000-A4 range consist of a manifold with integrated inline filter supplied together with a needle valve and pressure gauge. Optional available with temperature gauge and/or flow indicator. The unit is used to control the flushing of a mechanical seal.

TSA6

TSA6

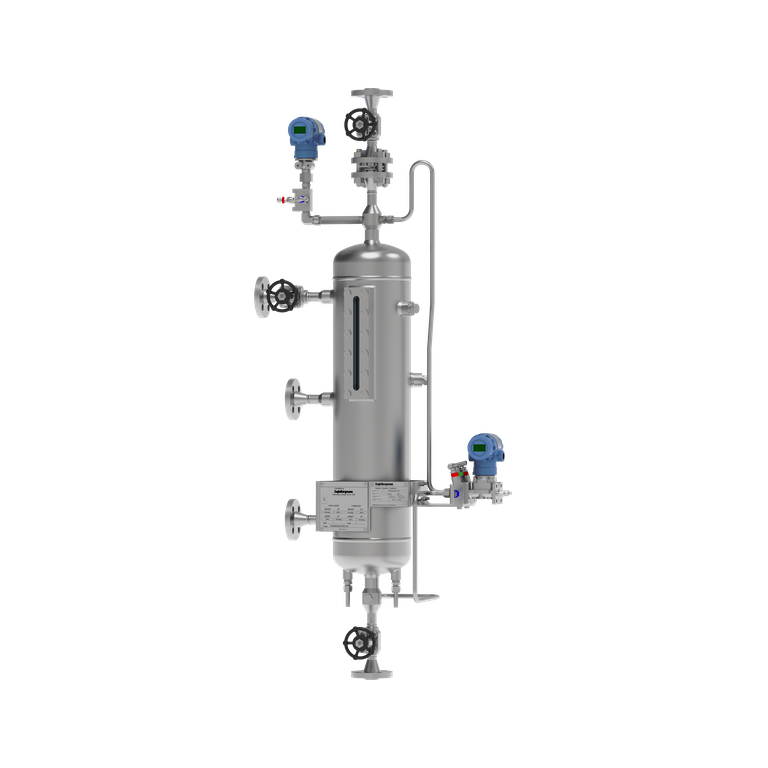

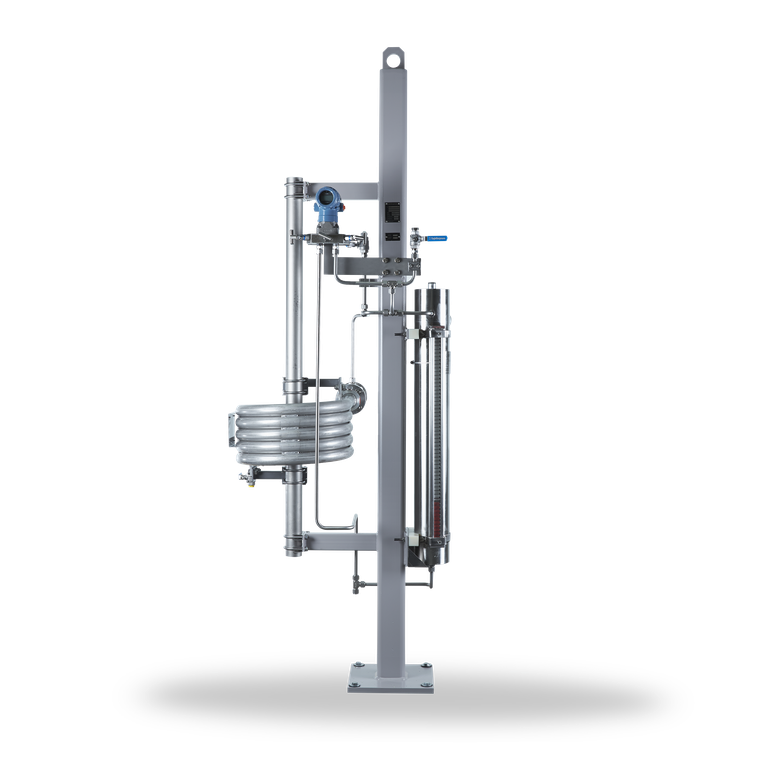

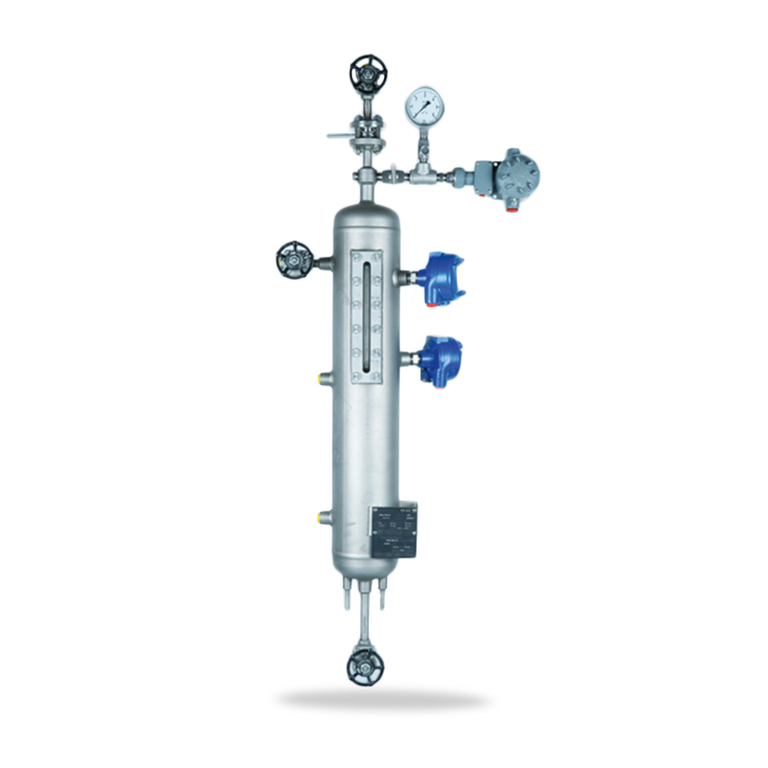

Barrier/buffer fluid systemThe EagleBurgmann barrier/buffer fluid systems of the TSA6000-A4 range meet all the requirements to supply mechanical seals in accordance with the API682 4th edition guidelines. The vessels are equipped with all essential connections for fitting additional components.

The range is available in two standard vessel sizes with dished heads, and a bottom-flanged version which can be dismantled (TSB6000-A4) is also available.

The modular system allows the TSA6000-A4 vessels to be combined with a wide range of system components such as level transmitter, pressure transmitter, base frame, etc.

GSS6000

GSS6000

Gas supply system

LSA6

LSA6

Leakage collection reservoirThe EagleBurgmann leakage control systems of the LSA6000 range in accordance with API Plan 65A consist of a leakage collection tank with integrated orifice and overflow pipe. The level can be monitored with the differential pressure transmitter which is supplied together with a five-way manifold valve.

QFT6

QFT6

Quench systemQuench fluid supply systems are used with single mechanical seals. They act as a convenient fluid reservoir. The QFT6000-A4 stainless steel tank is equipped with a sight-glass for monitoring the MIN/MAX filling level and can be fastened with a lug fixture.

LL9UC

LL9UC

MBS682-PTA

MBS682-PTA

WEL6

WEL6

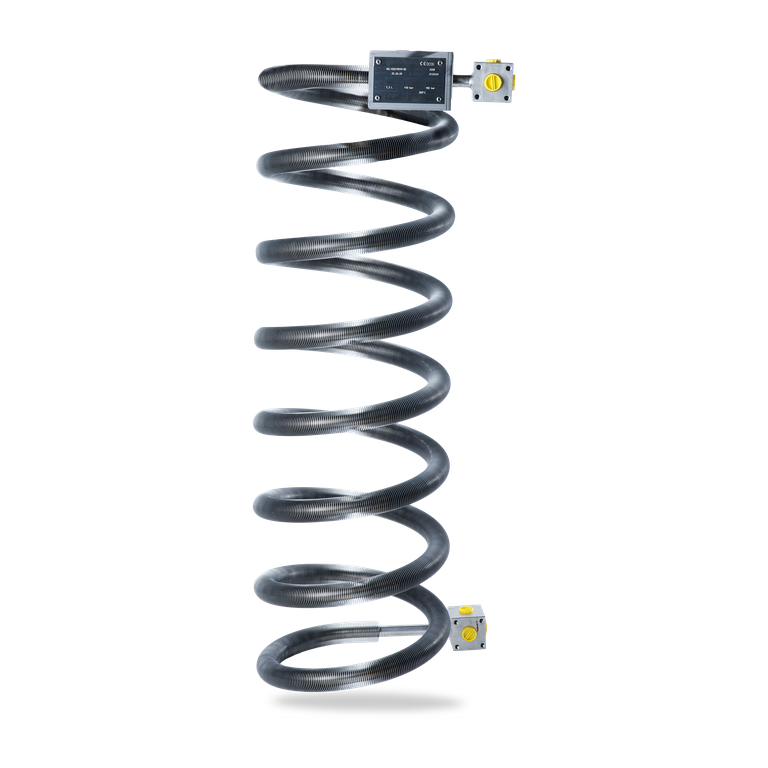

Air coolerHeat exchangers of the WEL6000-A4 range (shown here: WEL6002-A4) are used to cool process/barrier fluids in seal supply circuits. The heat exchangers are made of helical, laser-welded finned tubes. The cooling medium is ambient air. It is important, therefore, for WEL heat exchangers to be installed in well ventilated places indoors or, ideally, outdoors. There is a choice of three different basic versions of the WEL6000-A4 range as well as being supplied fully assembled together with valves, base frame and other system components.

TSB6

TSB6

Barrier/buffer fluid systemThe EagleBurgmann barrier/buffer fluid systems of the TSB6000-A4 range meet all the requirements to supply mechanical seals in accordance with the API682 4th edition guidelines. The vessels are equipped with all essential connections for fitting additional components.

TSB6 bottom-flanged vessels are available in two standard sizes. A version with dished heads (TSA6000-A4) is also available.

The modular system allows the TSB6000-A4 vessels to be combined with a wide range of system components, such as level transmitter, pressure transmitter, base frame, etc.

GSS6001

GSS6001

Gas supply system

LSB6

LSB6

Leakage collection reservoirIn accordance with API Plan 65B, the EagleBurgmann leakage control systems of the LSB6000 range consist of a leakage collection tank with valve and overflow pipe. The level can be monitored with the differential pressure transmitter which is supplied together with a five-way manifold valve.

H75A4-T

H75A4-T

MBS682P-D

MBS682P-D

SPB6 Barrier fluid system

SPB6 Barrier fluid system

with bladder accumulatorPressurized barrier system (closed circuit) for use in seal systems with high pressures and/or for hazardous/environmentally harmful processes. The SPB6000-A4 (Plan 53B) range is available with a pressure accumulator, cooler (finned tube, water or air cooler with fan) and a wide range of instruments.

A refilling unit has to be provided.

LSC6

LSC6

Leakage collection reservoirThe EagleBurgmann leakage control systems of the LSC6000-A4 range are utilized to collect condensing or mixed phase leakage - vapor passing through. A level indicator is installed to determine when the tank needs to be drained. A pressure gauge tracks and indicates seal leakage.

LL9DTUU

LL9DTUU

LY9TC

LY9TC

SPC6 Barrier fluid system

SPC6 Barrier fluid system

with piston accumulatorPressurized barrier system (closed circuit) for use in seal systems with high pressures and/or for hazardous/environmentally harmful processes.

The SPC6000-A4 (Plan 53C) range is available with a pressure booster, cooler (finned tube, water or air cooler with fan) and a wide range of instruments.

A refilling unit must be provided.

SPP6

SPP6

Leakage detection systemThe EagleBurgmann leakage control systems of the SPP6006-A4 range consist of a pressure transmitter which is supplied together with a block and bleed valve as well as an orifice and drain valve.

H75A4-C

H75A4-C

LY9DZTT

LY9DZTT

LL9DTUE

LL9DTUE

LY9DSTT

LY9DSTT

H75LG4-C

H75LG4-C

LY9SA

LY9SA

H75A4-B

H75A4-B

LY9DTSS

LY9DTSS

LL9DKUU

LL9DKUU

LY9DZSS

LY9DZSS

CGSH-KD

CGSH-KD

APItex-S

APItex-S

APItex-T

APItex-T

LEK777

LEK777

SH

SH

LL9DJUU

LL9DJUU

LL9DJUE

LL9DJUE

LL9DSUU

LL9DSUU

SH-D

SH-D

HRGS-DD

HRGS-DD

LNF992

LNF992

RGS-D

RGS-D

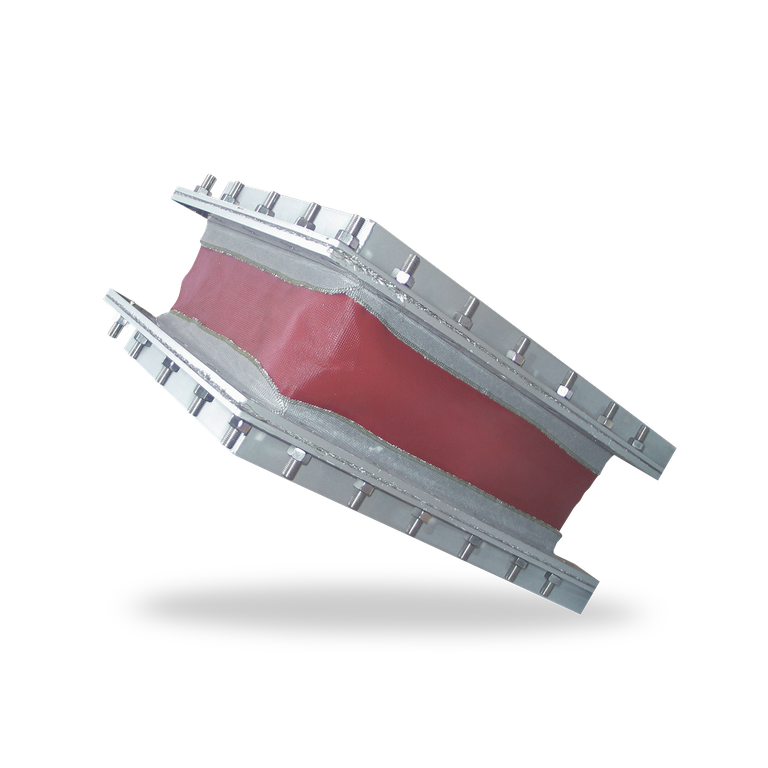

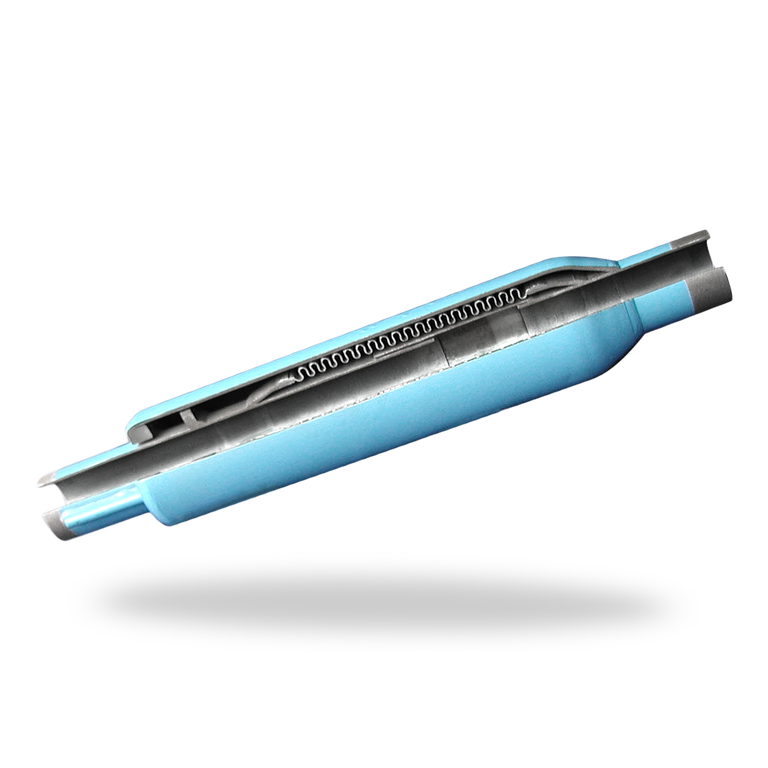

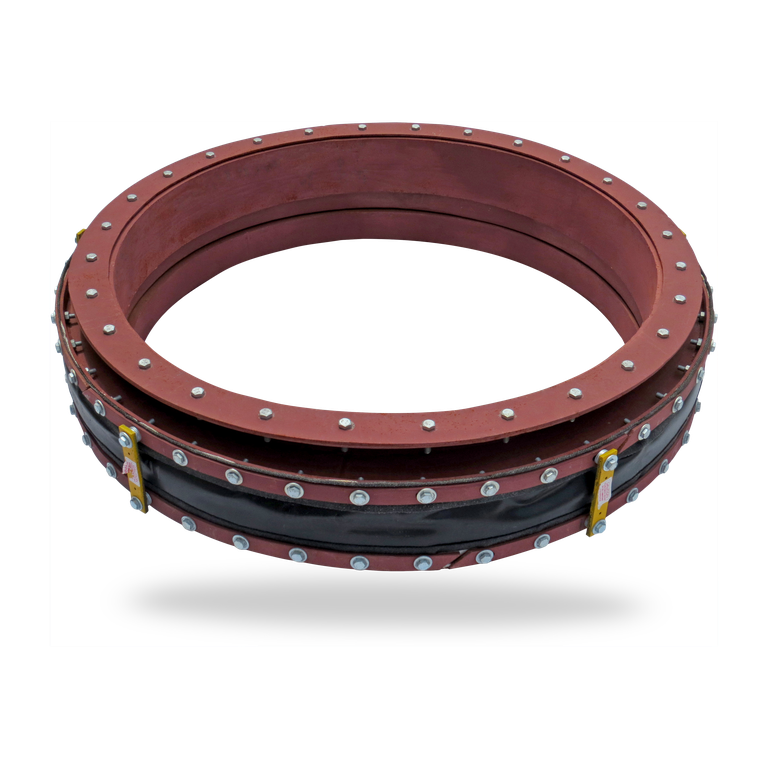

KE-Flex

KE-Flex

expansion joints

* Depending on material selection US Type

US Type

expansion joints

FCCUC Cold wall

FCCUC Cold wall

expansion joints

Fluachem

Fluachem

expansion joints

UM Type

UM Type

expansion joints

FCCUH Hot wall

FCCUH Hot wall

expansion joints

Fluastal

Fluastal

expansion joints

AX Type

AX Type

expansion joints

STY Styrene

STY Styrene

expansion joints

Combine-X

Combine-X

expansion joints

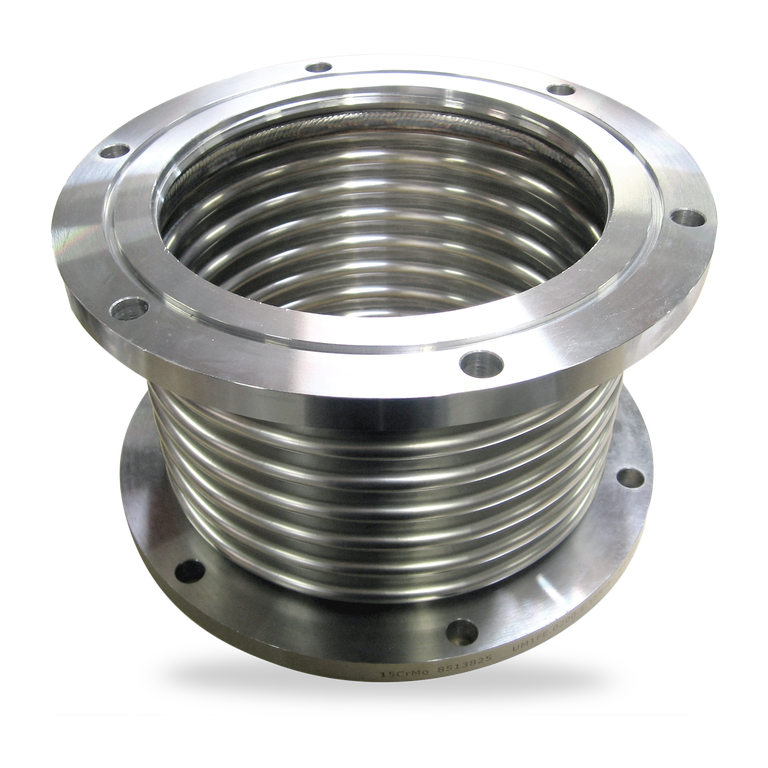

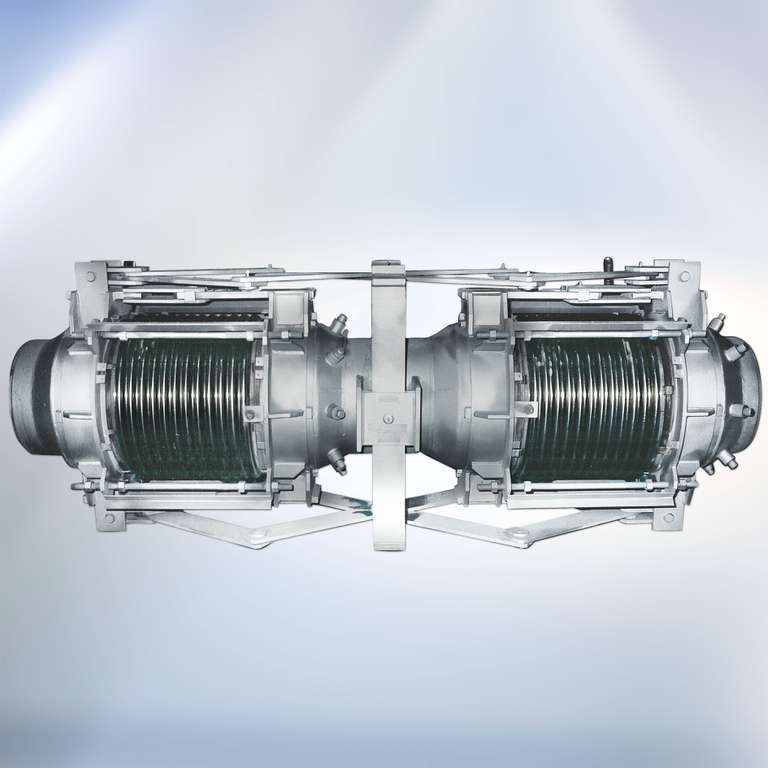

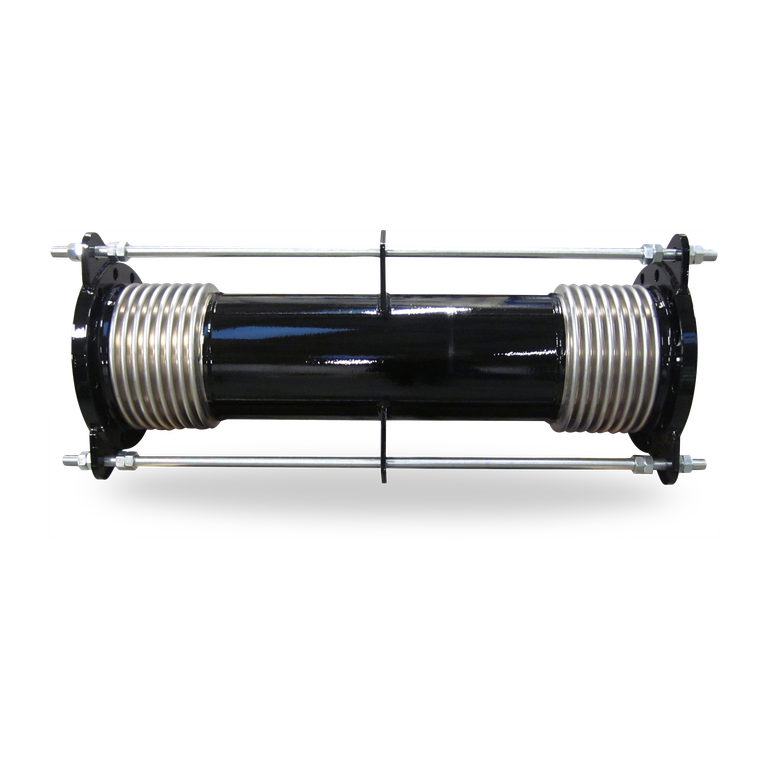

DX3S DanOne

DX3S DanOne

metal expansion joints

CX Codeflex

CX Codeflex

expansion joints

Fluaflex

Fluaflex

expansion joints

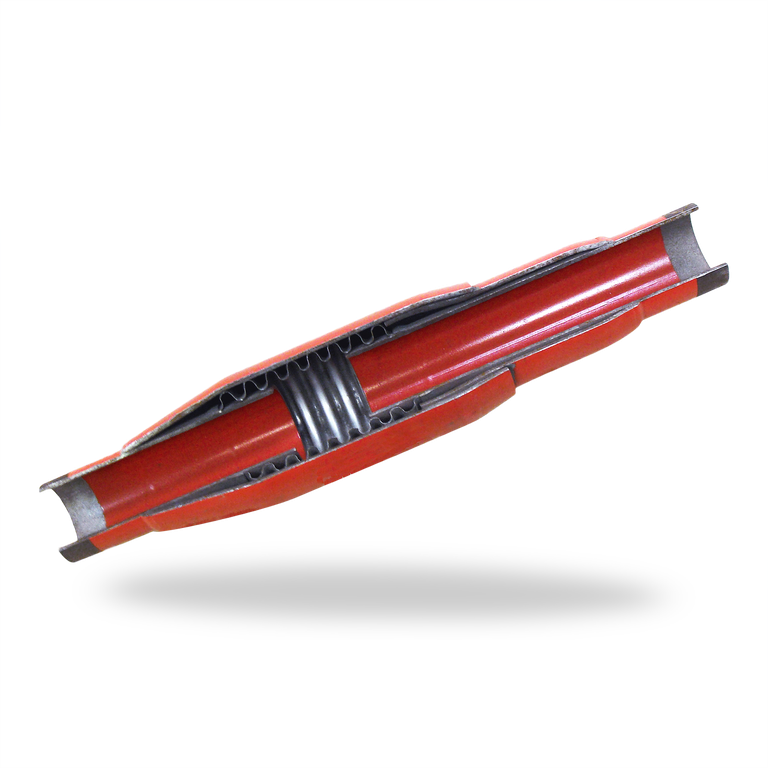

DH1S Danmuff

DH1S Danmuff

metal expansion joints

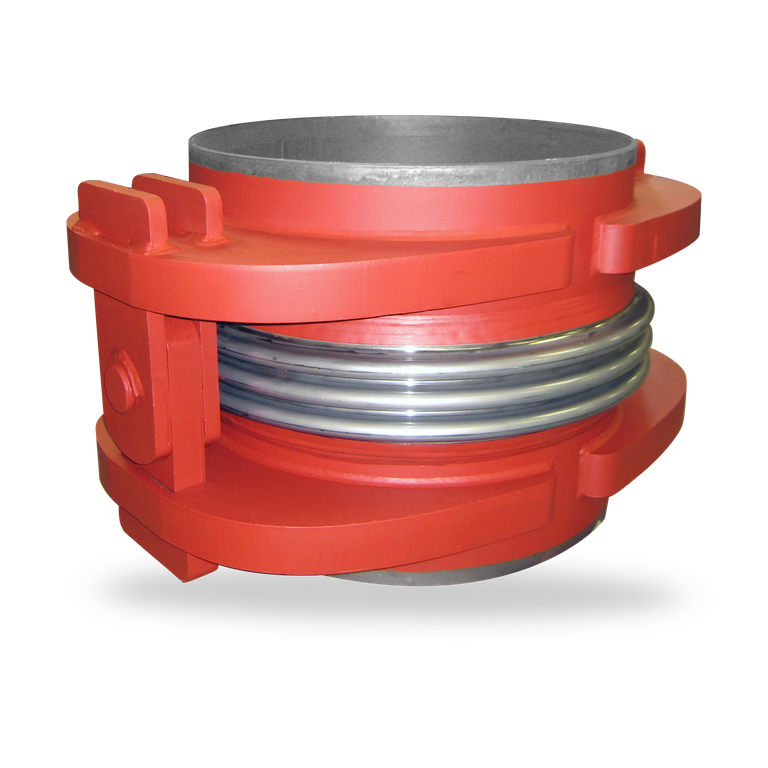

CB Clamshell

CB Clamshell

metal expansion joints

Flexgen

Flexgen

expansion joints

LA Type

LA Type

expansion joints

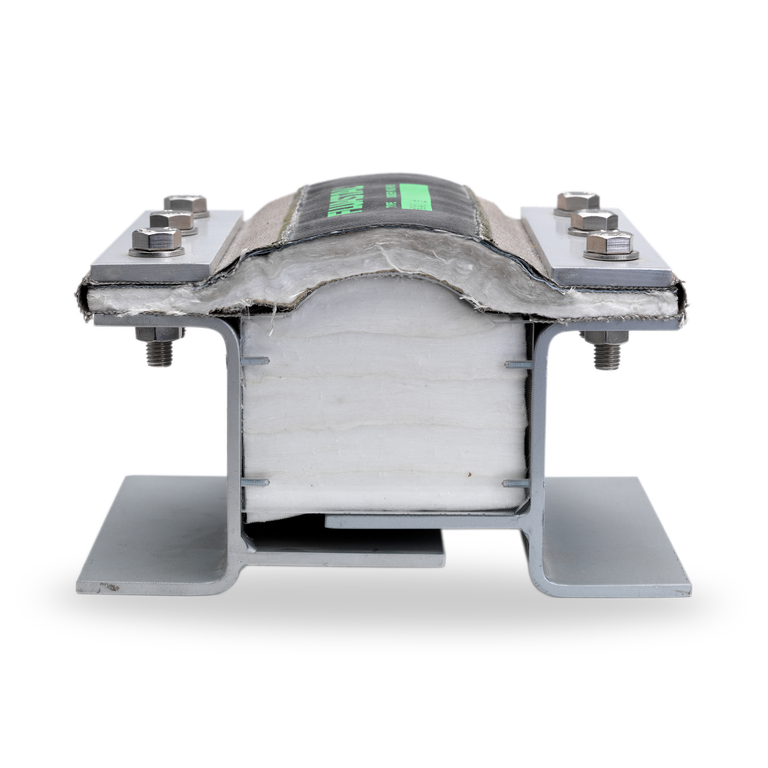

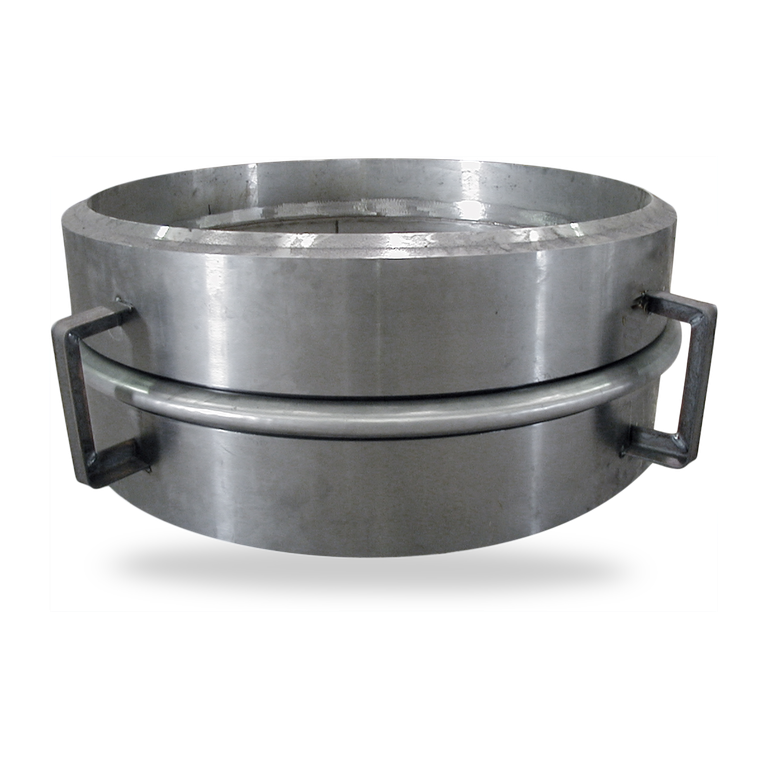

PSS

PSS

Penetration slider seal

Acouseal

Acouseal

expansion joint

AN Type

AN Type

expansion joints

TRD Toroid

TRD Toroid

expansion joints

Thermoflex

Thermoflex

expansion joints

UN Type

UN Type

expansion joints

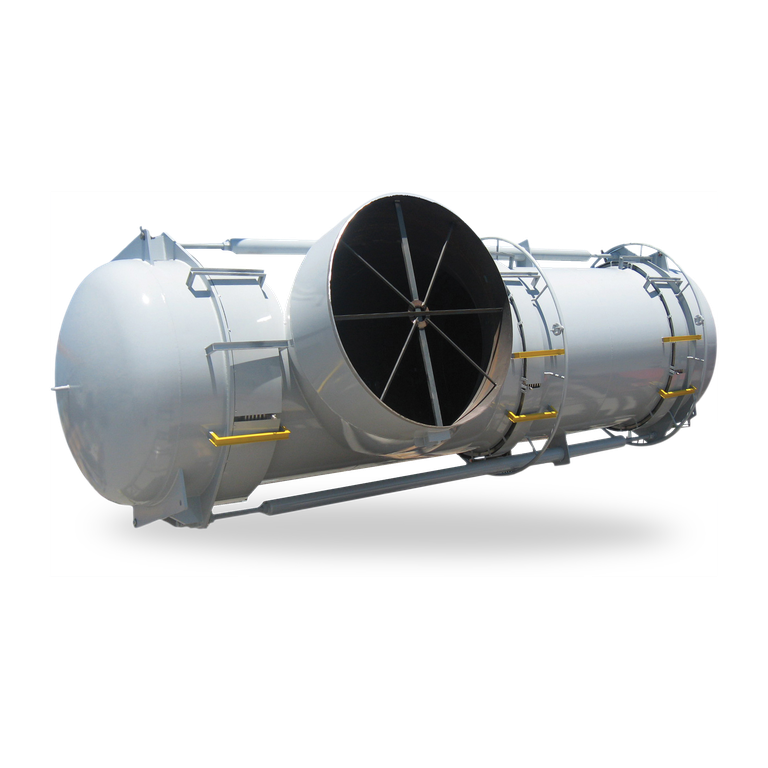

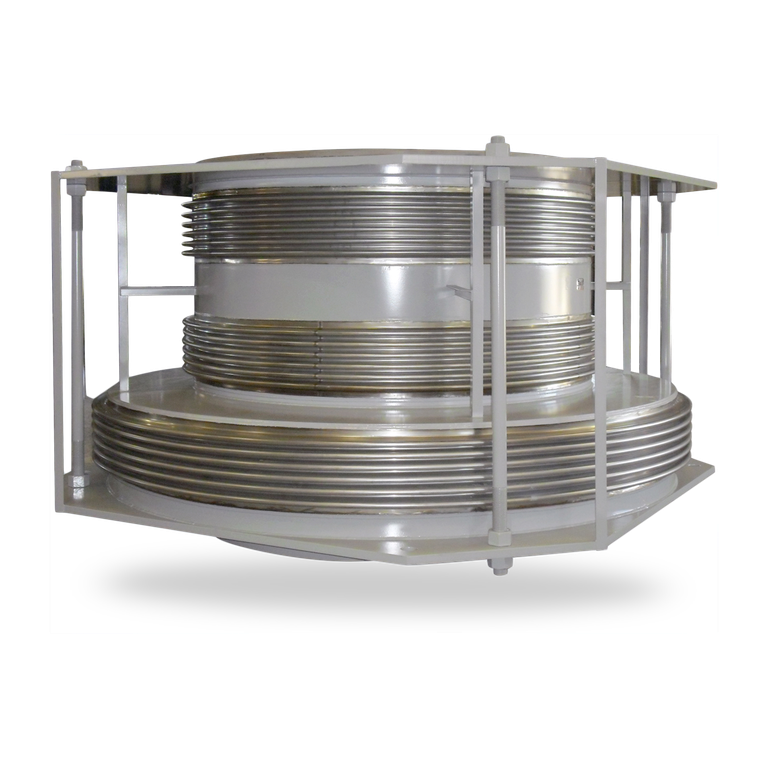

MGTX Gas turbine

MGTX Gas turbine

metal expansion joints

EX Type

EX Type

expansion joints

Penetration seal

Penetration seal

metal expansion joints

TB Type

TB Type

expansion joints

HA Type

HA Type

expansion joints

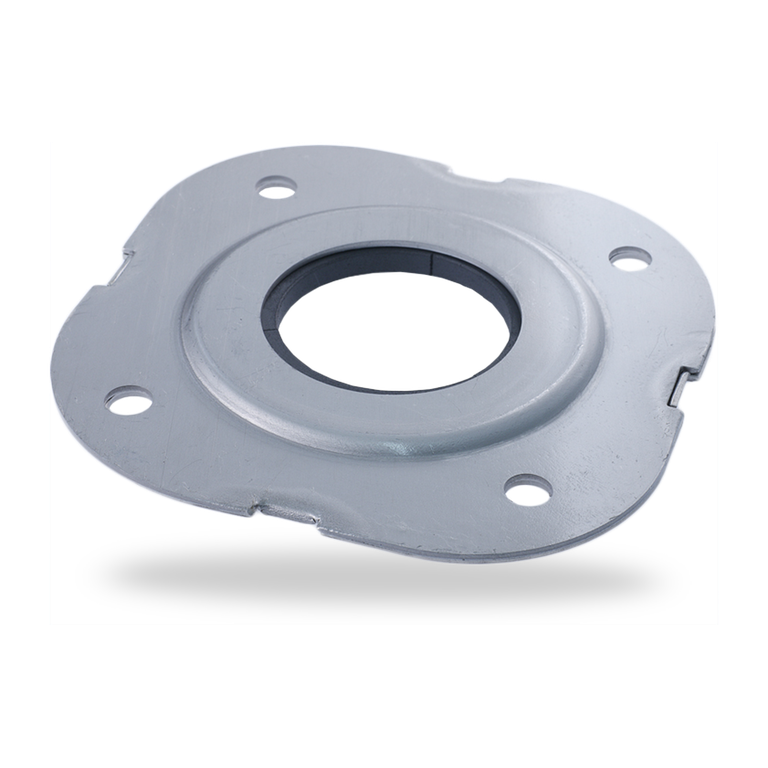

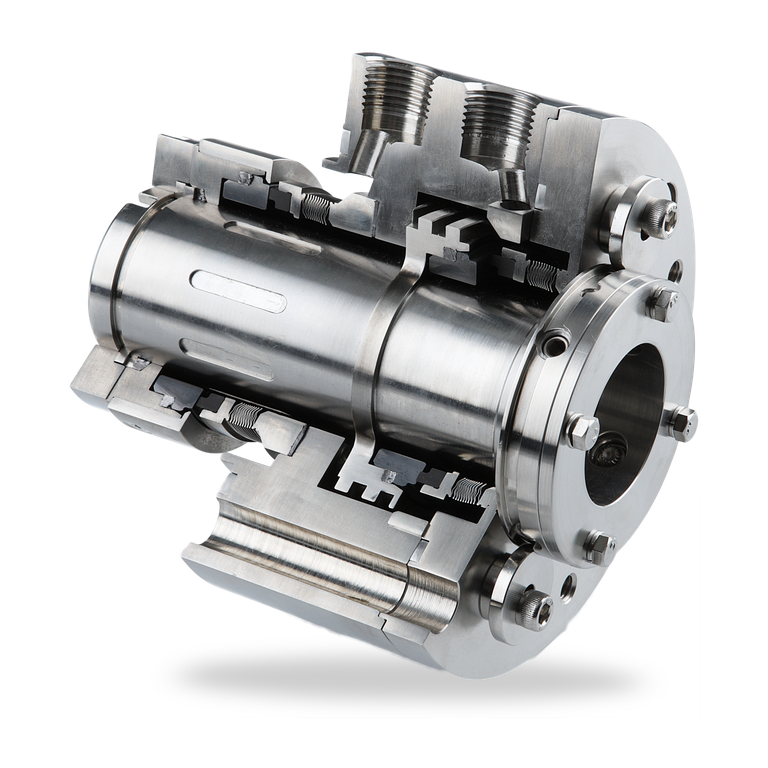

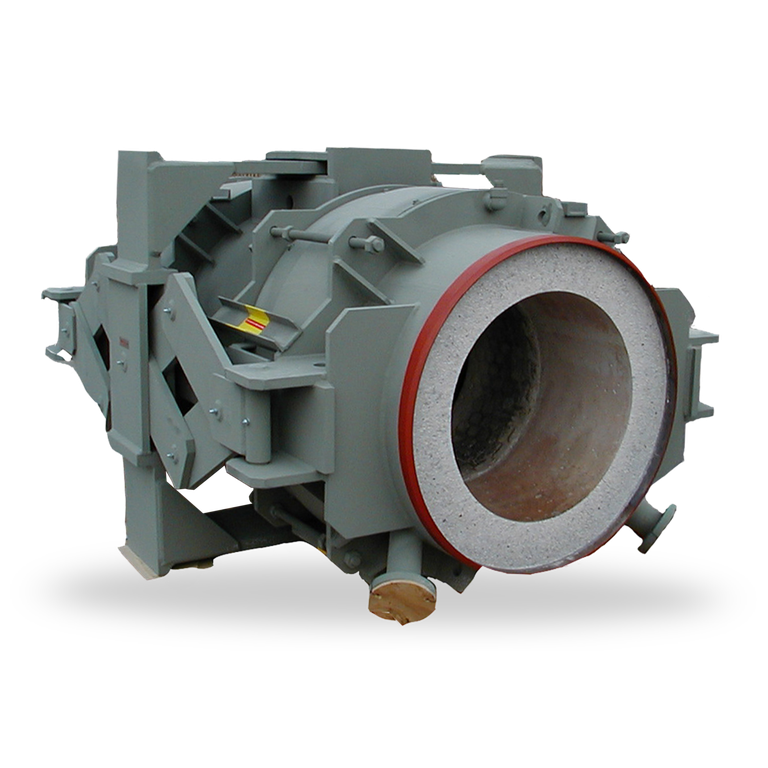

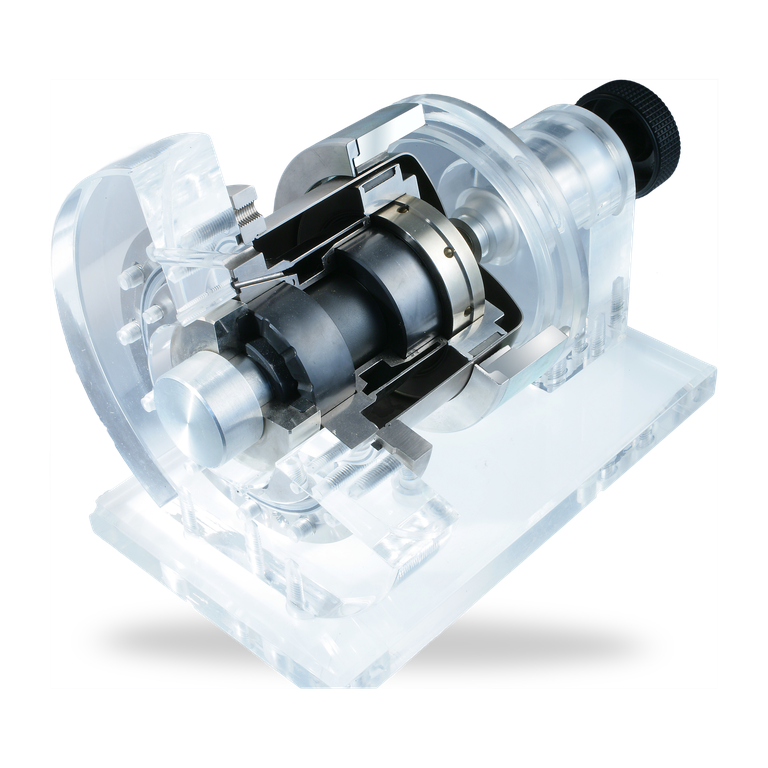

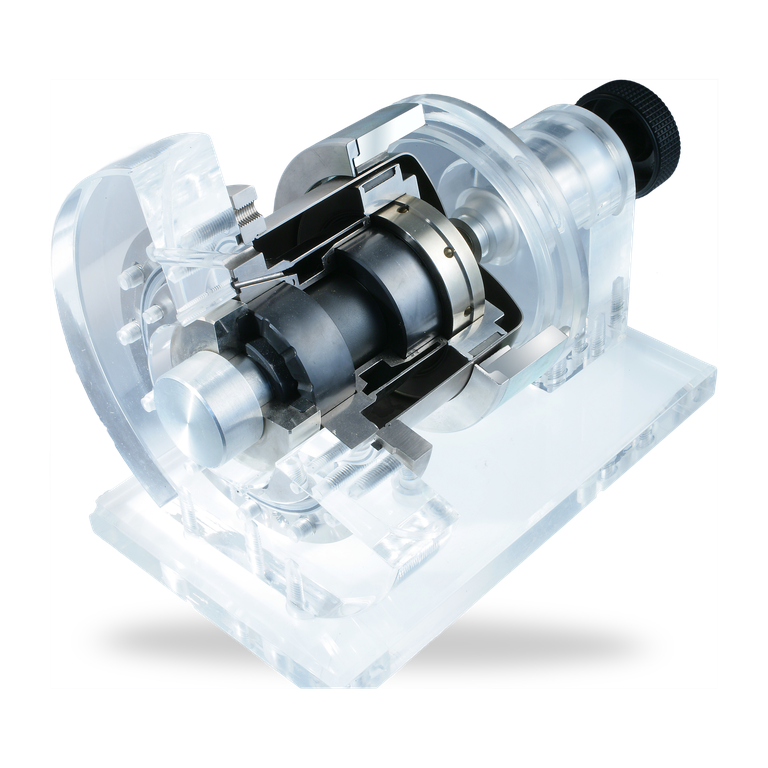

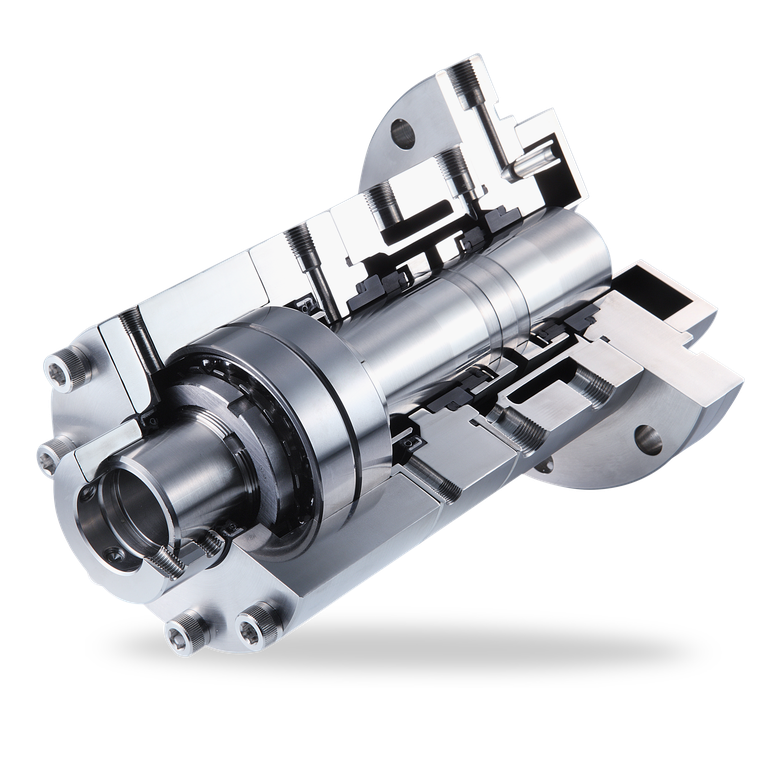

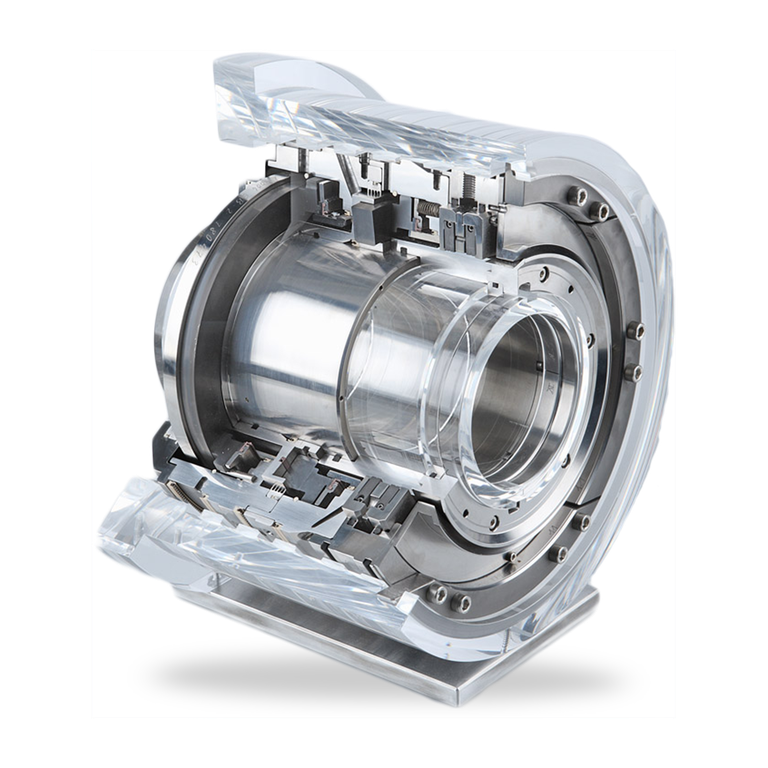

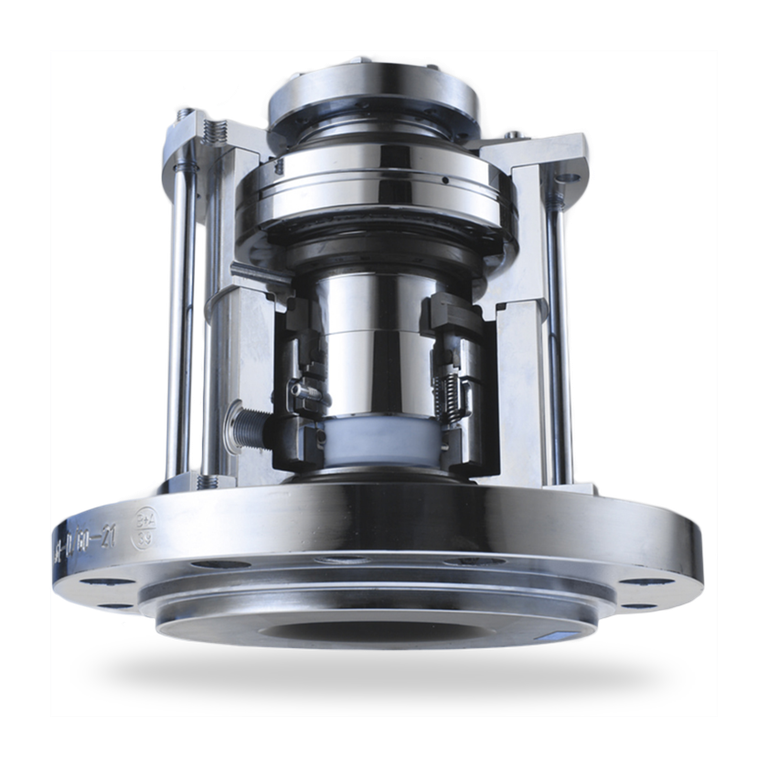

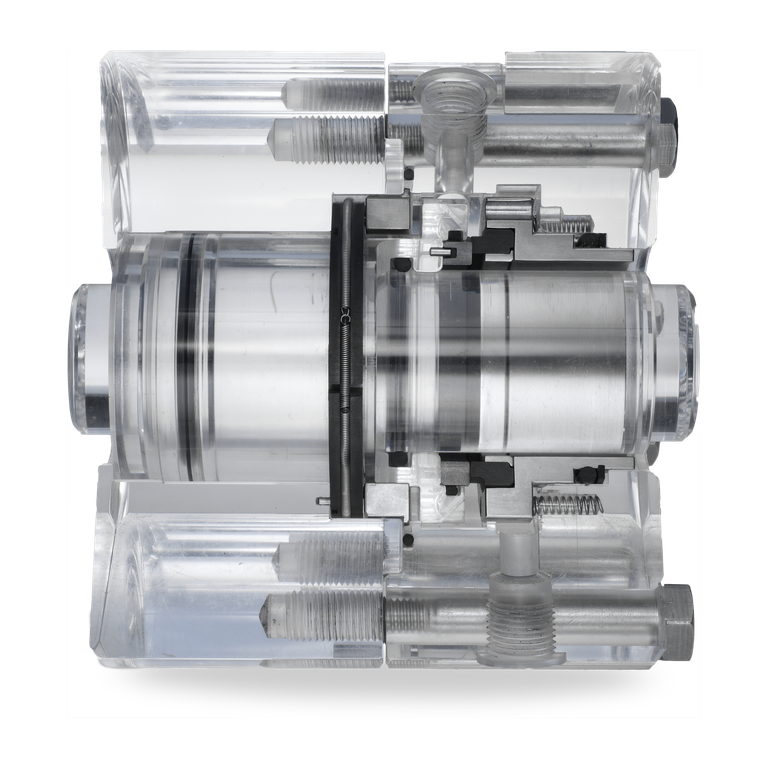

MAK66Magnetic couplings (MAK) are a hermetic sealing solution for pumps and agitators. Dangerous or precious media remains isolated in the closed system circuit.

MAK66Magnetic couplings (MAK) are a hermetic sealing solution for pumps and agitators. Dangerous or precious media remains isolated in the closed system circuit.

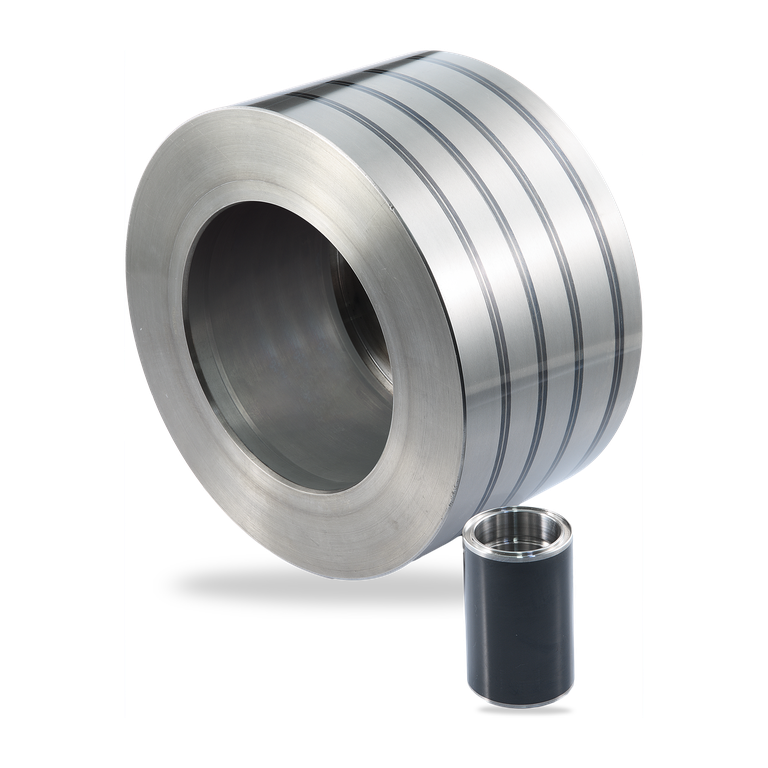

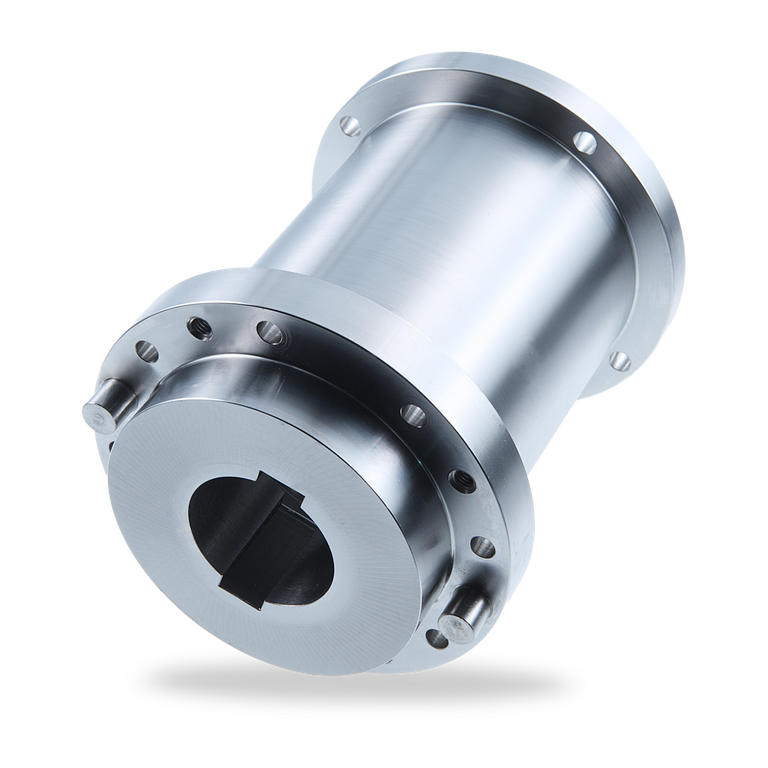

LMF1Sliding bearings are used for the shaft in magnetic coupled centrifugal or displacement pumps. The sliding parts are made of SiC. The pump liquid is circulating between the rotating and static parts to ensure lubrication and cooling. EagleBurgmann LMF bearings are successfully used for many years in applications worldwide. They are almost wearless and therefore extremely durable.

LMF1Sliding bearings are used for the shaft in magnetic coupled centrifugal or displacement pumps. The sliding parts are made of SiC. The pump liquid is circulating between the rotating and static parts to ensure lubrication and cooling. EagleBurgmann LMF bearings are successfully used for many years in applications worldwide. They are almost wearless and therefore extremely durable.

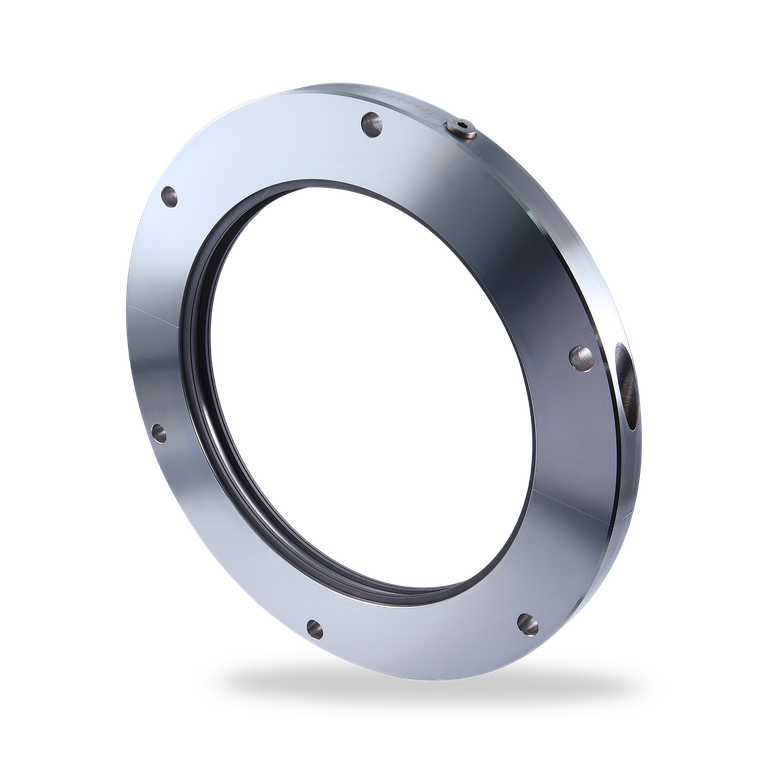

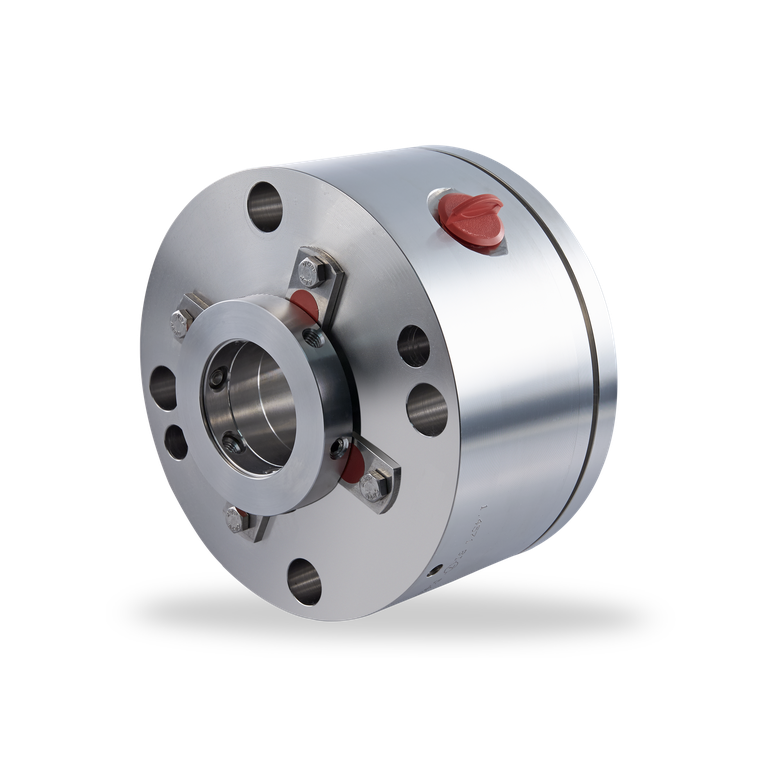

MAK685Magnetic couplings (MAK) are a hermetic sealing solution for pumps and agitators. Dangerous or precious media remain isolated in the closed system circuit.

MAK685Magnetic couplings (MAK) are a hermetic sealing solution for pumps and agitators. Dangerous or precious media remain isolated in the closed system circuit.

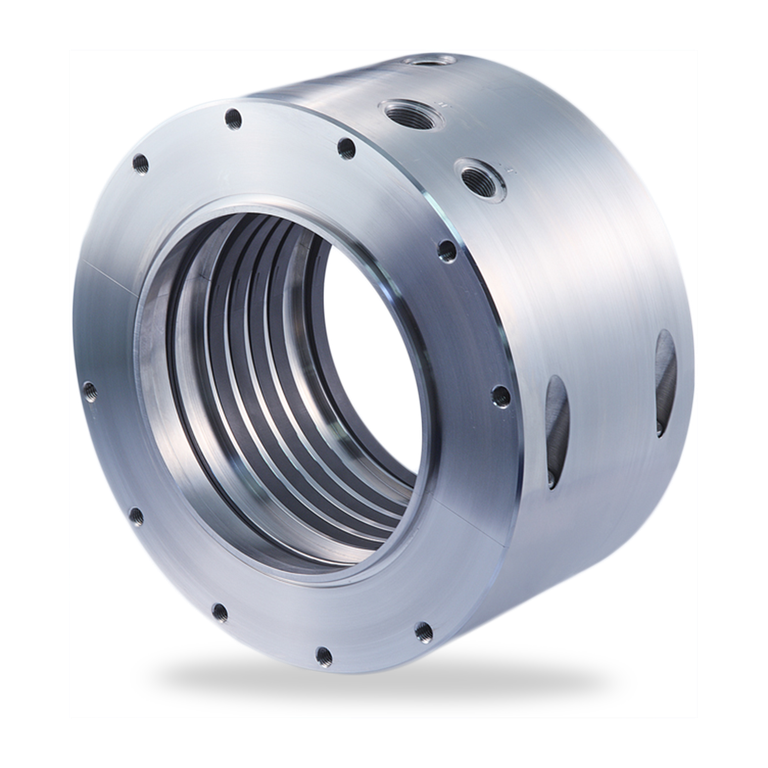

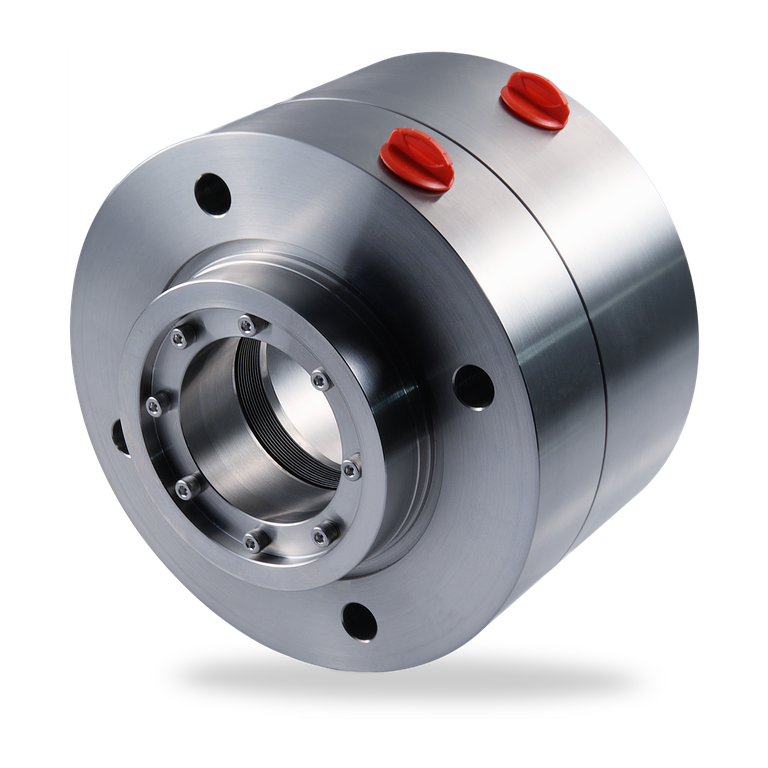

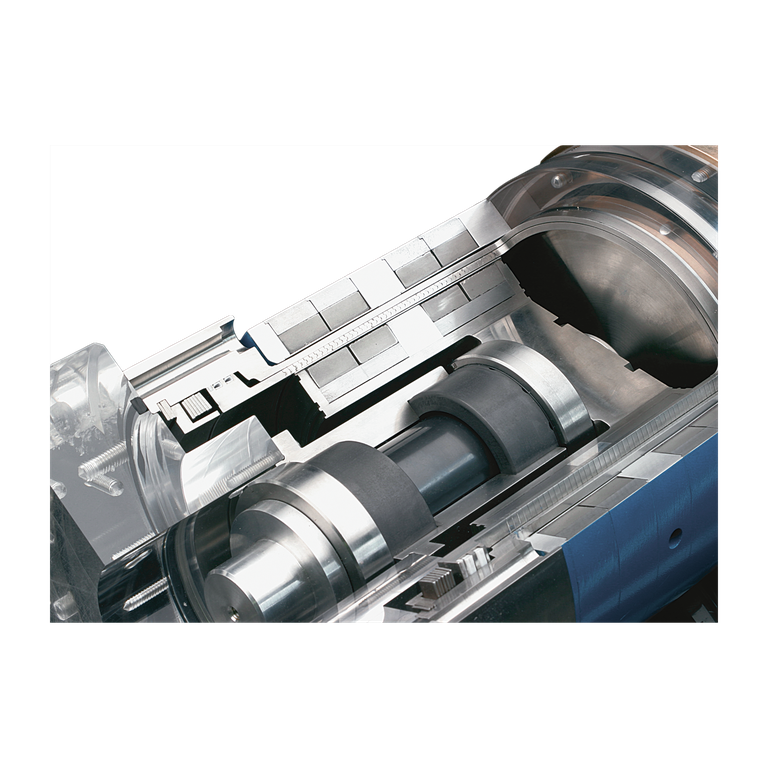

NMB High EfficiencyThe NMB series is used successful in many applications worldwide. The can is made from PTFE-seal insulated rings and a slotted outer can, what reduces EC-losses to a minimum. They are designed for increased safety and energy savings. Thus they can handle large motor torques, high speed and high pressure.

NMB High EfficiencyThe NMB series is used successful in many applications worldwide. The can is made from PTFE-seal insulated rings and a slotted outer can, what reduces EC-losses to a minimum. They are designed for increased safety and energy savings. Thus they can handle large motor torques, high speed and high pressure.

SMAKMagnetic couplings of the SMAK series are used to transfer torque into mixers and agitators. Top drive, bottom drive or lateral drive. Dangerous or precious media remain isolated in the closed vessel.

SMAKMagnetic couplings of the SMAK series are used to transfer torque into mixers and agitators. Top drive, bottom drive or lateral drive. Dangerous or precious media remain isolated in the closed vessel.

Industrial sector

Industrial sector Chemical industry Food and beverage industry Oil and gas industry Petrochemical industry Pharmaceutical industry Power plant technology Process industry Pulp and paper industry Refining technology Water and waste water technology

Index

Index BestFlow DHE Pressure accumulator DRE Pressure control unit DRU2000 ESPro Supply system for electrical submersible pumps GSS Gas supply system HPS Screw pump LS050 (Plan 65) LS050 (Plan 75) MAA Magnetic separator MAF203 Magnetic filter MAF2001 Magnetic filter MFU Multi Flow Unit QFT1000 QFT2000 QFT3000 QFT6000 RoTechBooster SMS Seal Management SP23 (Plan 76) SP23 Flow meter SP23 Pressure gauge SP23 Temperature gauge SPA SPI Measuring unit SPK Contact unit SPL Level indicator SPN SPN Automatic SPO (Plan 53B) SPO (Plan 53C) SPS Level switch SPU Circulation pump TS1000 TS2000 TS3000 TS3016 TS4000 TS5000 TS6000 VTE Distribution unit WDK WE WED WEL1000 WEL2000 ZY Cyclone separators

Search

QFT1000Quench fluid supply systems are used to supply single or tandem mechanical seals. They act as a convenient fluid reservoir. The exchange of fluid takes place by the thermosiphon principle or by forced circulation, e.g. with a pumping screw. The QFT1000 is made of transparent polyethylene, complete with clips made of stainless steel. The QFT1000 is resistant to water, glycerine, glycols and methanol; not resistant to mineral oils and toluene.

QFT1000Quench fluid supply systems are used to supply single or tandem mechanical seals. They act as a convenient fluid reservoir. The exchange of fluid takes place by the thermosiphon principle or by forced circulation, e.g. with a pumping screw. The QFT1000 is made of transparent polyethylene, complete with clips made of stainless steel. The QFT1000 is resistant to water, glycerine, glycols and methanol; not resistant to mineral oils and toluene.

Supply of mechnical seal in accordance with API 682 / ISO 21049, Plan 51.

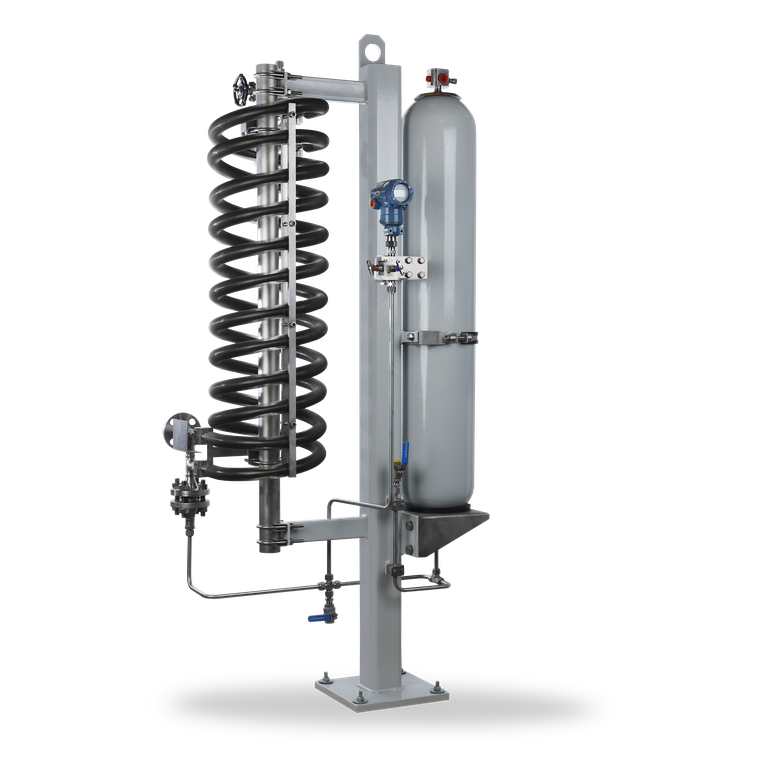

TS1000With the EagleBurgmann TS1016 thermosiphon system it is possible to supply buffer/barrier fluid to double and tandem mechanical seals for a broad range of applications. The TS1016 thermosiphon vessel is available in 2 standard sizes with flat ends, sight-glasses for level monitoring and with or without cooling coil. TS vessels are equipped as standard with all the necessary system connections and brackets. The modular system allows the TS1016 vessels to be combined with a wide range of system components such as, e.g. level switch, circulation pump, hand refill pump, thermometer, base frame, etc.

TS1000With the EagleBurgmann TS1016 thermosiphon system it is possible to supply buffer/barrier fluid to double and tandem mechanical seals for a broad range of applications. The TS1016 thermosiphon vessel is available in 2 standard sizes with flat ends, sight-glasses for level monitoring and with or without cooling coil. TS vessels are equipped as standard with all the necessary system connections and brackets. The modular system allows the TS1016 vessels to be combined with a wide range of system components such as, e.g. level switch, circulation pump, hand refill pump, thermometer, base frame, etc.

Circulation in accordance with API 682 / ISO 21 049: Plan 52, Plan 53A

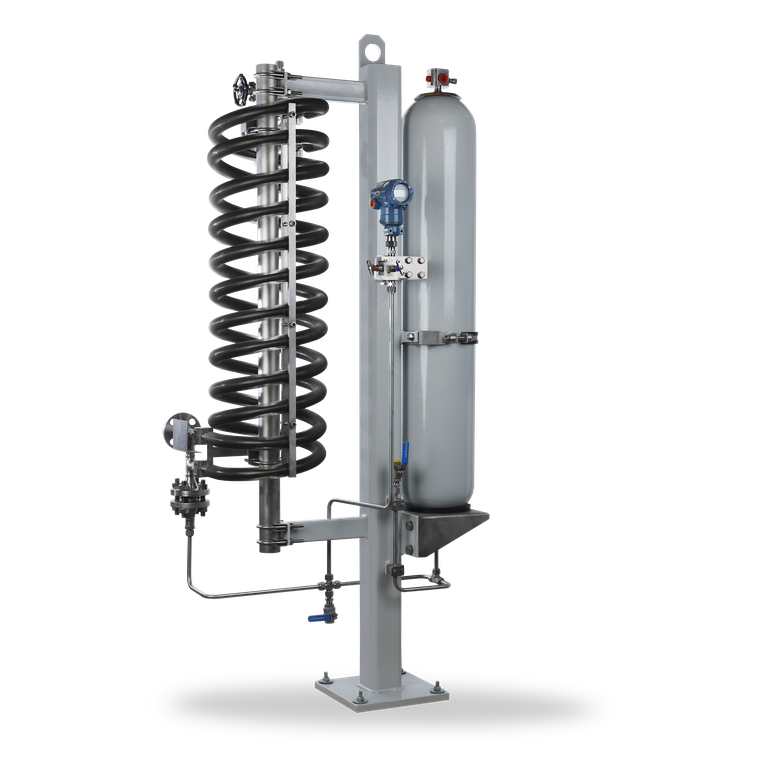

SPO (Plan 53B)Pressurized barrier system (closed circuit) for use in seal systems with high pressures and/or for hazardous/environmentally harmful processes. The SPO (Plan 53B) range is available with a pressure accumulator, cooler (finned tube, water or air cooler with fan) and a wide range of instruments.

SPO (Plan 53B)Pressurized barrier system (closed circuit) for use in seal systems with high pressures and/or for hazardous/environmentally harmful processes. The SPO (Plan 53B) range is available with a pressure accumulator, cooler (finned tube, water or air cooler with fan) and a wide range of instruments.

Circulation in accordance with API 682 / ISO 21049: Plan 53B

DRU2000With the EagleBurgmann DRU system it is possible to supply barrier fluid to double and tandem mechanical seals for a broad range of applications. The maximum operating pressure of 63 bar applies to the housing of the pressure booster, i.e. the process/medium pressure at the connection must be lower and is conditional on the transmission ratio:

DRU2000With the EagleBurgmann DRU system it is possible to supply barrier fluid to double and tandem mechanical seals for a broad range of applications. The maximum operating pressure of 63 bar applies to the housing of the pressure booster, i.e. the process/medium pressure at the connection must be lower and is conditional on the transmission ratio:

DRU2063/A001 up to 57 bar

DRU2063/A002 up to 42 bar

Circulation in accordance with API 682 / ISO 21049: Plan 53C

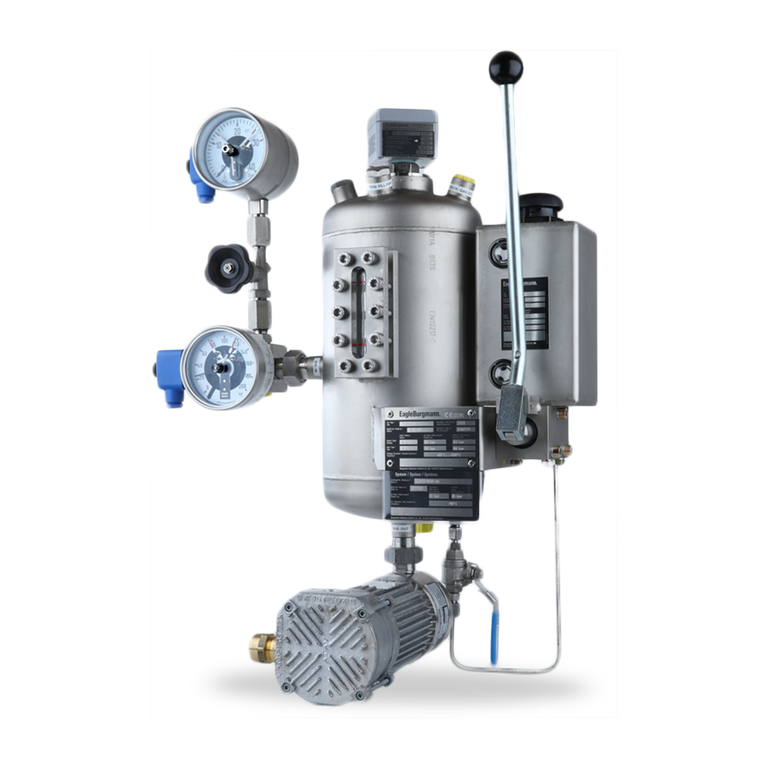

SPABarrier pressure units of the SPA range perform all the functions of a barrier system essential for operating double seals (circulation and cooling of the barrier medium, pressurization of the barrier fluid and compensation of leakage).

SPABarrier pressure units of the SPA range perform all the functions of a barrier system essential for operating double seals (circulation and cooling of the barrier medium, pressurization of the barrier fluid and compensation of leakage).

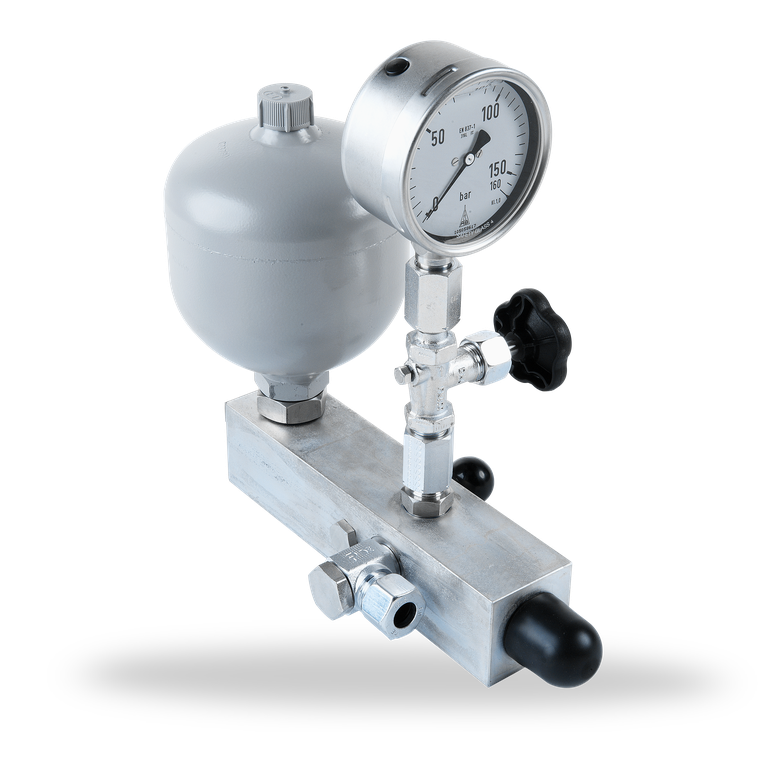

DHE Pressure accumulatorThe DHE consists of an accumulator, a pressure gauge with a shut-off valve and a check valve. The DHE can also be retrofitted to an SPA (Conversion kit no.: DHE140/R001-00).

DHE Pressure accumulatorThe DHE consists of an accumulator, a pressure gauge with a shut-off valve and a check valve. The DHE can also be retrofitted to an SPA (Conversion kit no.: DHE140/R001-00).

SPNThe hand refill pump (shown: SPN4016) consists of a storage vessel with level indicator, filling filter and a hand pump with integrated check valve. It is mounted directly on the thermosiphon vessel or pressure booster. There is a choice of two basic types in the SPN range of products:

SPNThe hand refill pump (shown: SPN4016) consists of a storage vessel with level indicator, filling filter and a hand pump with integrated check valve. It is mounted directly on the thermosiphon vessel or pressure booster. There is a choice of two basic types in the SPN range of products:

SPN2000: Stainless steel refill pump for universal applications

SPN4000: specifically for use with TS1016 systems

SPN AutomaticThe SPN is an automatic refill unit for barrier fluid pressurization in seal circuits. Pressurization by pneumatic or electric power, or a combination of both. The refill unit tank is designed for pressureless operation and is equipped with a level switch and a sight-glass. The refill unit has all pipework as far as the distributor unit. Separate components are installed in the seal circuit to cool and to circulate the barrier medium.

SPN AutomaticThe SPN is an automatic refill unit for barrier fluid pressurization in seal circuits. Pressurization by pneumatic or electric power, or a combination of both. The refill unit tank is designed for pressureless operation and is equipped with a level switch and a sight-glass. The refill unit has all pipework as far as the distributor unit. Separate components are installed in the seal circuit to cool and to circulate the barrier medium.

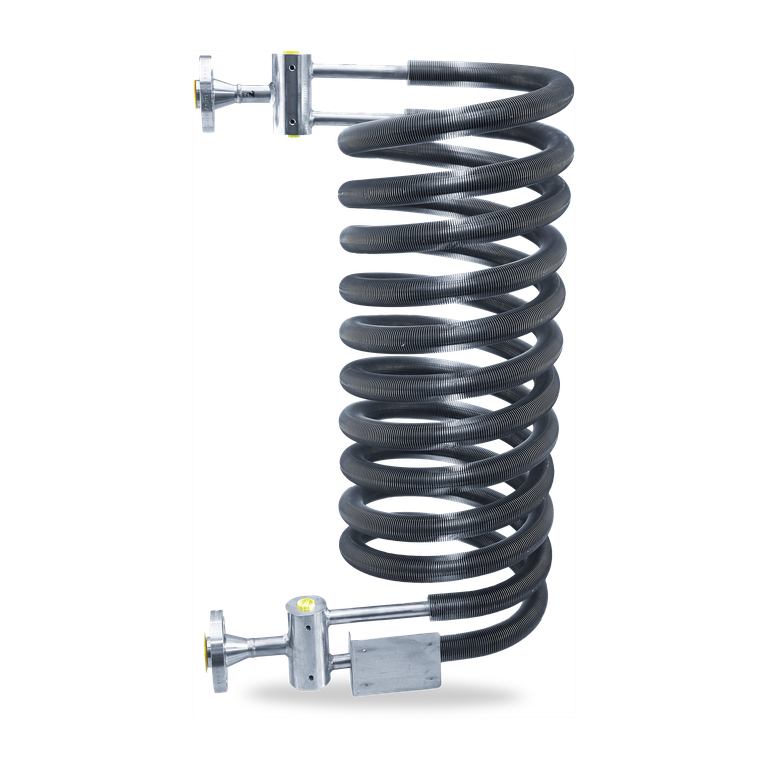

WDKWDK5120 heat exchangers are used to cool process/barrier fluids in seal supply circuits. The heat exchanger has a wound double helix around the guide tube. Process/barrier medium in the tubes, cooling medium around the tubes.

WDKWDK5120 heat exchangers are used to cool process/barrier fluids in seal supply circuits. The heat exchanger has a wound double helix around the guide tube. Process/barrier medium in the tubes, cooling medium around the tubes.

Circulation in accordance with API 682 / ISO 21049: Plan 21, Plan 22, Plan 23, Plan 41.

QFT2000Quench fluid supply systems are used to supply single or tandem mechanical seals. They act as a convenient fluid reservoir. The exchange of fluid takes place by the thermosiphon principle or by forced circulation, e.g. with a pumping screw. The QFT2000 stainless steel tank is equipped with sight-glasses for monitoring the MIN/MAX level and can be fastened with a lug fixture. The leakage overflow can be selectively discharged.

QFT2000Quench fluid supply systems are used to supply single or tandem mechanical seals. They act as a convenient fluid reservoir. The exchange of fluid takes place by the thermosiphon principle or by forced circulation, e.g. with a pumping screw. The QFT2000 stainless steel tank is equipped with sight-glasses for monitoring the MIN/MAX level and can be fastened with a lug fixture. The leakage overflow can be selectively discharged.

Supply of mechanical seal in accordance with API 682 / ISO 21049, Plan 51.

TS2000With the EagleBurgmann TS2000 thermosiphon system it is possible to supply buffer/barrier fluid to double and tandem mechanical seals for a broad range of applications. The range is available in 2 different pressure levels with dished heads, sight-glass for level monitoring and with or without cooling coil. TS vessels are equipped as standard with all the necessary system connections and brackets. The modular system allows the TS2000 vessels to be combined with a wide range of system components such as, level switch, circulation pump, hand refill pump, thermometer, base frame, etc.

TS2000With the EagleBurgmann TS2000 thermosiphon system it is possible to supply buffer/barrier fluid to double and tandem mechanical seals for a broad range of applications. The range is available in 2 different pressure levels with dished heads, sight-glass for level monitoring and with or without cooling coil. TS vessels are equipped as standard with all the necessary system connections and brackets. The modular system allows the TS2000 vessels to be combined with a wide range of system components such as, level switch, circulation pump, hand refill pump, thermometer, base frame, etc.

Circulation in accordance with API 682 / ISO 21 049: Plan 52, Plan 53A

SPO (Plan 53C)Pressurized barrier system (closed circuit) for use in seal systems with high pressures and/or for hazardous/environmentally harmful processes. The SPO Plan 53C range is available with a pressure booster, cooler (finned tube, water or air cooler with fan) and a wide range of instruments.

SPO (Plan 53C)Pressurized barrier system (closed circuit) for use in seal systems with high pressures and/or for hazardous/environmentally harmful processes. The SPO Plan 53C range is available with a pressure booster, cooler (finned tube, water or air cooler with fan) and a wide range of instruments.

Circulation in accordance with API 682 / ISO 21049: Plan 53C

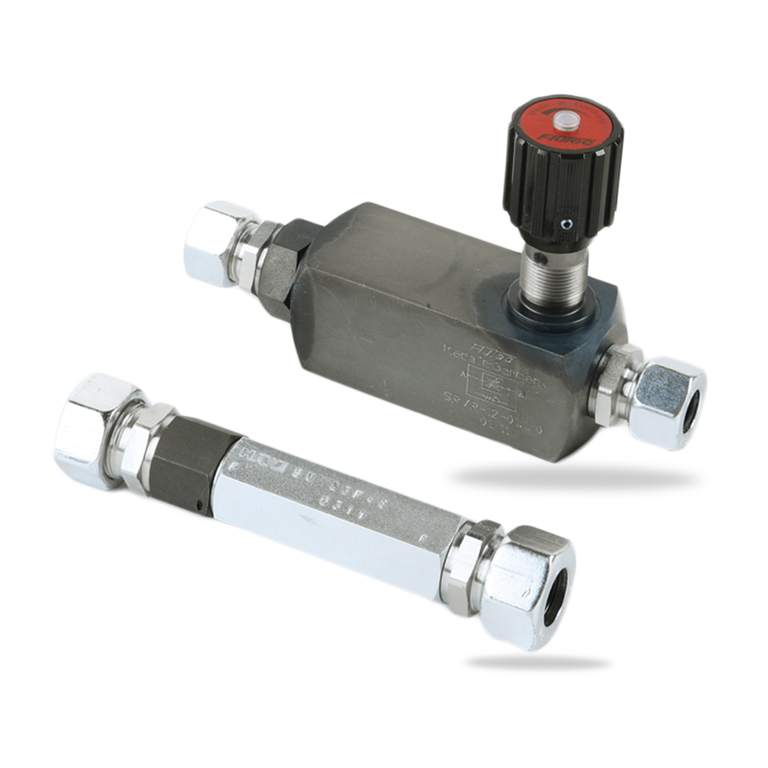

DRE Pressure control unitThe pressure control unit is used for setting different levels of barrier pressure when supplying several individual mechanical seals via an SPA with a VTE. There is a choice of four basic types.

DRE Pressure control unitThe pressure control unit is used for setting different levels of barrier pressure when supplying several individual mechanical seals via an SPA with a VTE. There is a choice of four basic types.

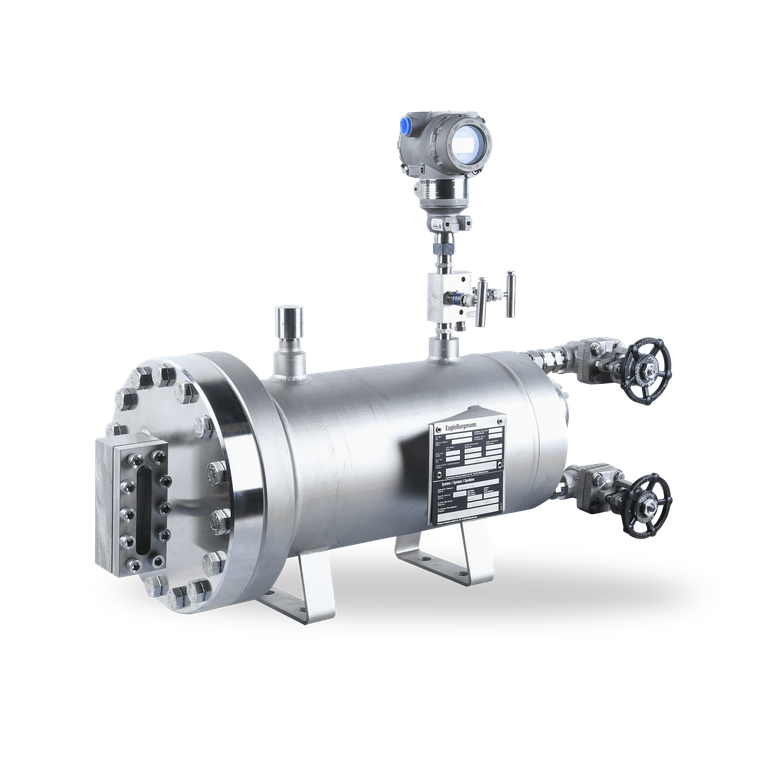

WEDHeat exchangers of the WED range are used to cool process/barrier fluids in seal supply circuits. Designed as a tubular heat exchanger with integrated guide plates, the process/barrier medium is directed through the shell of the WED and the cooling medium through the tubes.

WEDHeat exchangers of the WED range are used to cool process/barrier fluids in seal supply circuits. Designed as a tubular heat exchanger with integrated guide plates, the process/barrier medium is directed through the shell of the WED and the cooling medium through the tubes.

Circulation in accordance with API 682 / ISO 21 049: Plan 21, Plan 22, Plan 23, Plan 41

QFT3000Quench fluid supply systems are used to supply single or tandem mechanical seals. They act as a convenient fluid reservoir. The exchange of fluid takes place by the thermosiphon principle or by forced circulation, e.g. with a pumping screw. The QFT3000 stainless steel tank is equipped with a sight-glass for monitoring the MIN filling level and can be fastened with a lug fixture.

QFT3000Quench fluid supply systems are used to supply single or tandem mechanical seals. They act as a convenient fluid reservoir. The exchange of fluid takes place by the thermosiphon principle or by forced circulation, e.g. with a pumping screw. The QFT3000 stainless steel tank is equipped with a sight-glass for monitoring the MIN filling level and can be fastened with a lug fixture.

Supply of mechanical seal in accordance with API 682 / ISO 21049, Plan 51.

TS3000Thermosiphon systems of the TS3000 range designed specifically for the operation and supply of mechanical seals in sterile processes. The TS3000 thermosiphon vessel is available in two standard sizes, designed for dismantling, with cooling coil. The modular system allows the TS3000 vessels to be combined with a wide range of system components.

TS3000Thermosiphon systems of the TS3000 range designed specifically for the operation and supply of mechanical seals in sterile processes. The TS3000 thermosiphon vessel is available in two standard sizes, designed for dismantling, with cooling coil. The modular system allows the TS3000 vessels to be combined with a wide range of system components.

Circulation in accordance with API 682 / ISO 21 049: Plan 52, Plan 53A

VTE Distribution unitThe distribution unit is used when two or more mechanical seals are to be supplied from a single barrier fluid unit of the SPA1000, SPA2000 or SPA3000 range. The VTE is suitable for hydraulic oil as barrier medium. It is delivered as a separate unit which the customer must install in the pipe work at a suitable position. There is a choice of two basic types:

VTE Distribution unitThe distribution unit is used when two or more mechanical seals are to be supplied from a single barrier fluid unit of the SPA1000, SPA2000 or SPA3000 range. The VTE is suitable for hydraulic oil as barrier medium. It is delivered as a separate unit which the customer must install in the pipe work at a suitable position. There is a choice of two basic types:

VTE02/M...: Distribution unit for supplying two or more mechanical seals in between bearing pumps.

VTE../S...: Distribution unit for supplying two or more mechanical seals in different pumps. It contains an overflow valve and one flow control valve per seal. DRE pressure control units are necessary if different barrier pressures are used on the mechanical seals.

WEHeat exchangers of the WE range are used to cool process/barrier fluids in seal supply circuits. WE heat exchangers are available in two standard sizes and are API 682 conform. The process/barrier medium is directed through the tube and the cooling medium through the shell.

WEHeat exchangers of the WE range are used to cool process/barrier fluids in seal supply circuits. WE heat exchangers are available in two standard sizes and are API 682 conform. The process/barrier medium is directed through the tube and the cooling medium through the shell.

For simple draining or venting of the cooling water side, the heat exchanger can also be supplied with ventilation/drainage ball valves. In addition, the heat exchangers can also be combined with a temperature instrument in the supply line to the mechanical seal (optional in accordance with API 682).

Circulation in accordance with API 682 / ISO 21 049: Plan 21, Plan 22, Plan 23, Plan 41

QFT6000Quench fluid supply systems are used to supply single mechanical seals. They act as a convenient fluid reservoir. The QFT6000 stainless steel tank is equipped with a sight-glass for monitoring the MIN/MAX filling level and can be fastened with a lug fixture.

QFT6000Quench fluid supply systems are used to supply single mechanical seals. They act as a convenient fluid reservoir. The QFT6000 stainless steel tank is equipped with a sight-glass for monitoring the MIN/MAX filling level and can be fastened with a lug fixture.

Supply of mechnical seal in accordance with API 682 / ISO 21049, Plan 51.

TS3016The EagleBurgmann TS3016 thermosiphon system presents a simple and quick way to clean the vessel interior. For this purpose it is designed for easy dismantling. A quick-release coupling should therefore be used to connect the pressure gas to the vessel. The modular system allows the TS3016 vessels to be combined with a wide range of system components.

TS3016The EagleBurgmann TS3016 thermosiphon system presents a simple and quick way to clean the vessel interior. For this purpose it is designed for easy dismantling. A quick-release coupling should therefore be used to connect the pressure gas to the vessel. The modular system allows the TS3016 vessels to be combined with a wide range of system components.

Circulation in accordance with API 682 / ISO 21049: Plan 52, Plan 53A

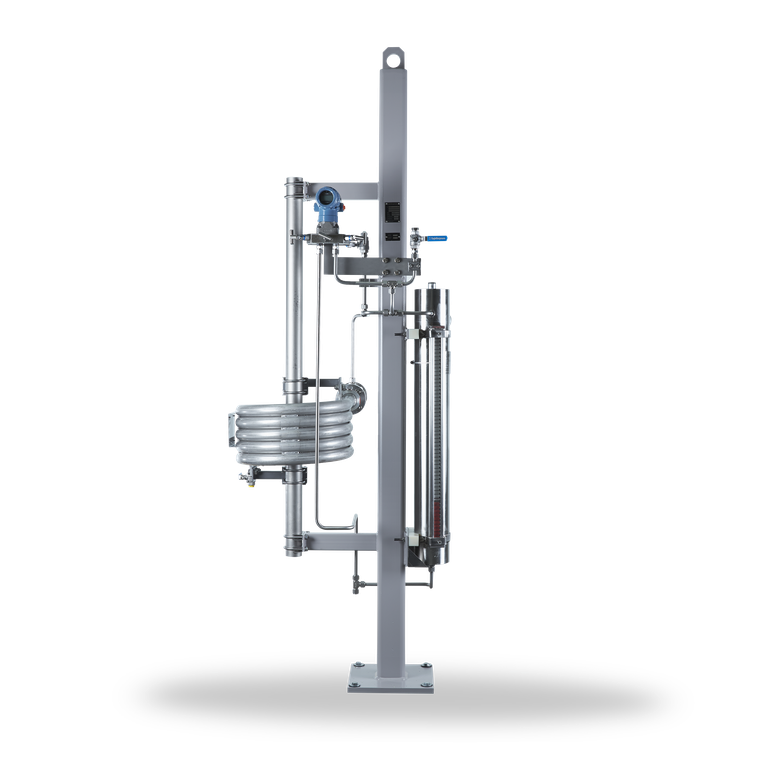

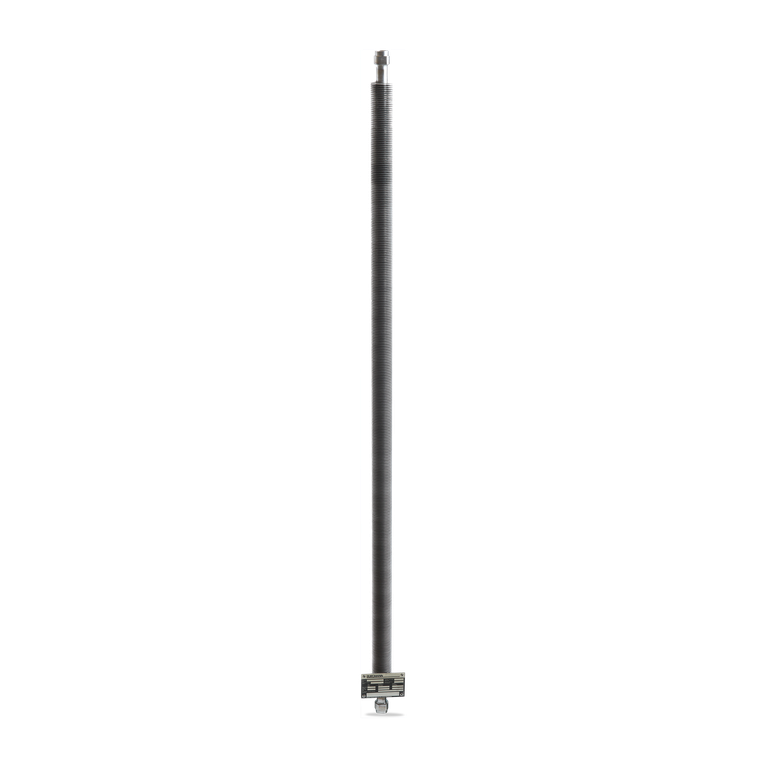

WEL1000Heat exchangers of the WEL1000 range are used to cool process/barrier fluids in seal supply circuits. The heat exchangers are made of straight, laser-welded finned tubes. The cooling medium is ambient air. It is important, therefore, for WEL heat exchangers to be installed in well ventilated places indoors or, ideally, outdoors. There is a choice of two different basic versions of the WEL1000 range (1 or 2 tubes), supplied fully assembled along with valves, base frame and other system components.

WEL1000Heat exchangers of the WEL1000 range are used to cool process/barrier fluids in seal supply circuits. The heat exchangers are made of straight, laser-welded finned tubes. The cooling medium is ambient air. It is important, therefore, for WEL heat exchangers to be installed in well ventilated places indoors or, ideally, outdoors. There is a choice of two different basic versions of the WEL1000 range (1 or 2 tubes), supplied fully assembled along with valves, base frame and other system components.

Circulation in accordance with API 682 / ISO 21049: Plan 21, Plan 22, Plan 23, Plan 41

TS4000With the EagleBurgmann gap-free executed TS4000 thermosiphon system it is possible to supply buffer/barrier fluid to double and tandem mechanical seals for a broad range of applications. The range is available in compley gap-free design with torispherical heads, sight-glass for level monitoring and with cooling coil. TS vessels are equipped as standard with all the necessary system connections and brackets.

TS4000With the EagleBurgmann gap-free executed TS4000 thermosiphon system it is possible to supply buffer/barrier fluid to double and tandem mechanical seals for a broad range of applications. The range is available in compley gap-free design with torispherical heads, sight-glass for level monitoring and with cooling coil. TS vessels are equipped as standard with all the necessary system connections and brackets.

Circulation in accordance with API 682 / ISO 21049: Plan 52, Plan 53A

WEL2000Heat exchangers of the WEL2000 range (shown: WEL2001/A040) are used to cool process/barrier fluids in seal supply circuits. The heat exchangers are made of helical, laser-welded finned tubes. The cooling medium is ambient air. There is a choice of three different basic versions of the WEL2000 range, supplied fully assembled along with valves, base frame and other system components.

WEL2000Heat exchangers of the WEL2000 range (shown: WEL2001/A040) are used to cool process/barrier fluids in seal supply circuits. The heat exchangers are made of helical, laser-welded finned tubes. The cooling medium is ambient air. There is a choice of three different basic versions of the WEL2000 range, supplied fully assembled along with valves, base frame and other system components.

Circulation in accordance with API 682 / ISO 21049: Plan 21, Plan 22, Plan 23, Plan 41

TS5000With the gap-free executed EagleBurgmann TS5000 thermosiphon system it is possible to supply buffer/barrier fluid to double and tandem mechanical seals for a broad range of applications. This range is designed as a flanged version with a sight-glass for level monitoring and with cooling coil. TS vessels are equipped as standard with all the necessary system connections and brackets.

TS5000With the gap-free executed EagleBurgmann TS5000 thermosiphon system it is possible to supply buffer/barrier fluid to double and tandem mechanical seals for a broad range of applications. This range is designed as a flanged version with a sight-glass for level monitoring and with cooling coil. TS vessels are equipped as standard with all the necessary system connections and brackets.

Circulation in accordance with API 682 / ISO 21049: Plan 52, Plan 53A

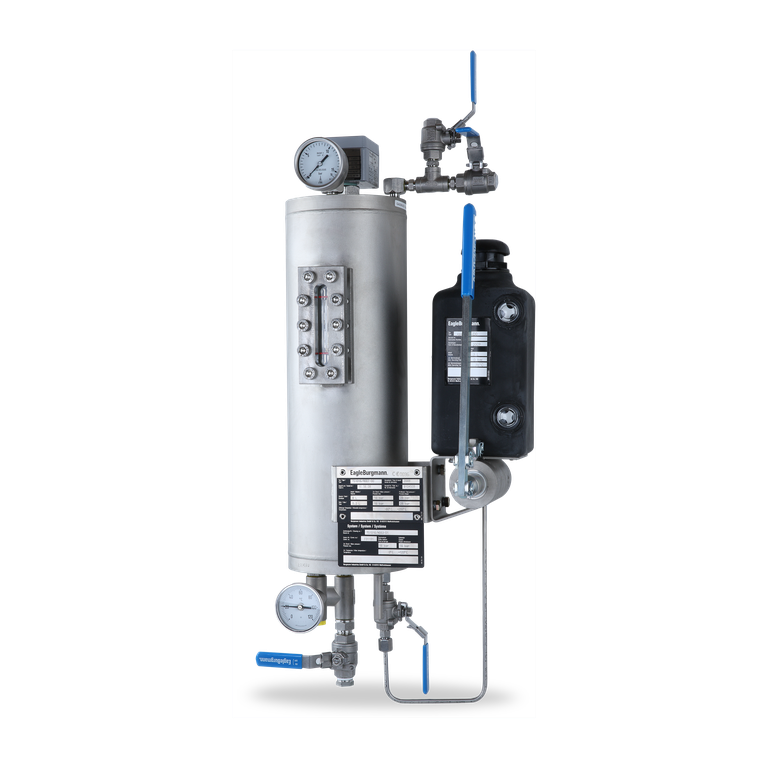

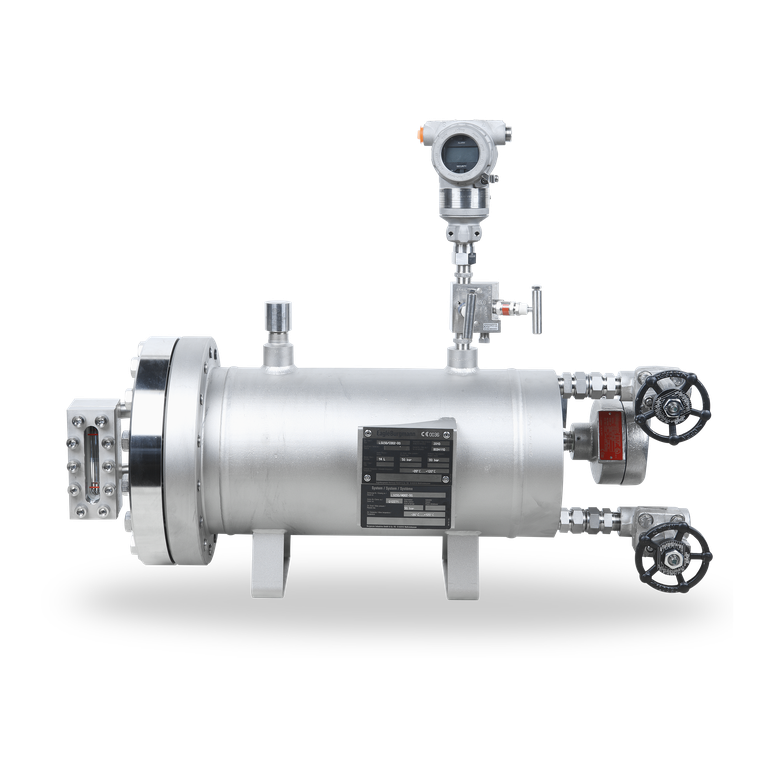

TS6000The EagleBurgmann Thermosiphon systems of the TS6000 range meet all the requirements to supply mechanical seals in accordance with the API 682 guidelines. The vessels are equipped with all essential connections for fitting additional components. The range is available in two standard vessel sizes (shown: TS6000) with dished heads; a version which can be dismantled is also available as an option. The modular system allows the TS6000 vessels to be combined with a wide range of system components such as, level switch/transmitter, pressure switch/transmitter, base frame, etc.

TS6000The EagleBurgmann Thermosiphon systems of the TS6000 range meet all the requirements to supply mechanical seals in accordance with the API 682 guidelines. The vessels are equipped with all essential connections for fitting additional components. The range is available in two standard vessel sizes (shown: TS6000) with dished heads; a version which can be dismantled is also available as an option. The modular system allows the TS6000 vessels to be combined with a wide range of system components such as, level switch/transmitter, pressure switch/transmitter, base frame, etc.

Circulation in accordance with API 682 / ISO 21049: Plan 52, Plan 53A

LS050 (Plan 65)The EagleBurgmann leakage control systems of the LS050 range in accordance with API Plan 65 consist of a leakage collection tank with integrated orifice and overflow pipe along with two shut-off valves. The level can be monitored with the a level switch.

LS050 (Plan 65)The EagleBurgmann leakage control systems of the LS050 range in accordance with API Plan 65 consist of a leakage collection tank with integrated orifice and overflow pipe along with two shut-off valves. The level can be monitored with the a level switch.

Circulation in accordance with API 682 / ISO 21049: Plan 65

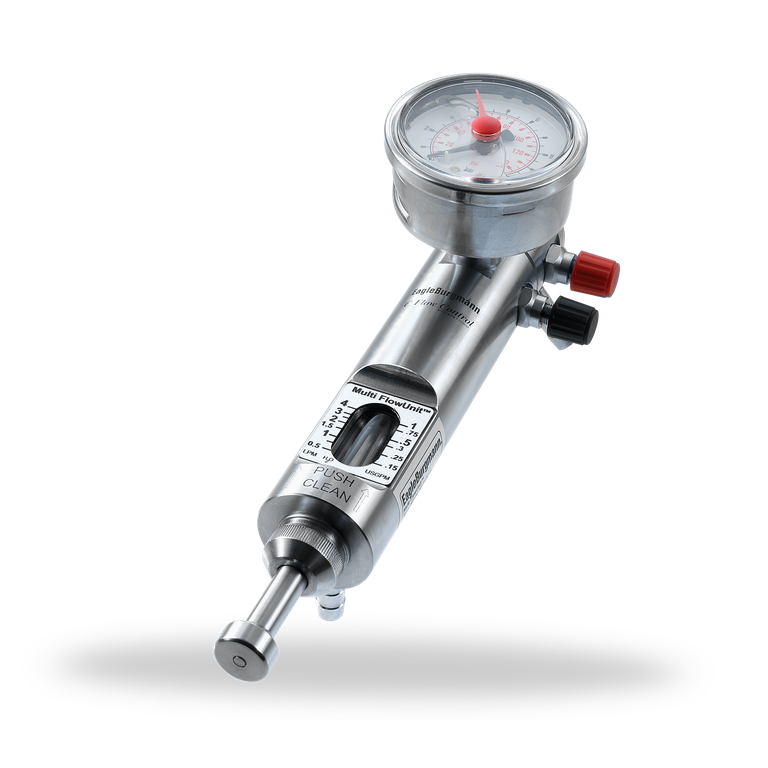

MFU Multi Flow UnitThe Multi Flow Unit (MFU) is an economical sealing water management solution for reducing operating costs through minimized rates of fresh water and waste water. The MFU series is available in three basic versions:

MFU Multi Flow UnitThe Multi Flow Unit (MFU) is an economical sealing water management solution for reducing operating costs through minimized rates of fresh water and waste water. The MFU series is available in three basic versions:

MFU-MP: for single seals with flush

MFU-MQ: for seals with quench

MFU-MD: for double seals

These are available for different indicated flow ranges and with numerous system components (e.g. mounting supports, stands, hoses, alarm sensors, etc.) and other material combinations.

Circulation in accordance with API 682 Plan 32, Plan 62.

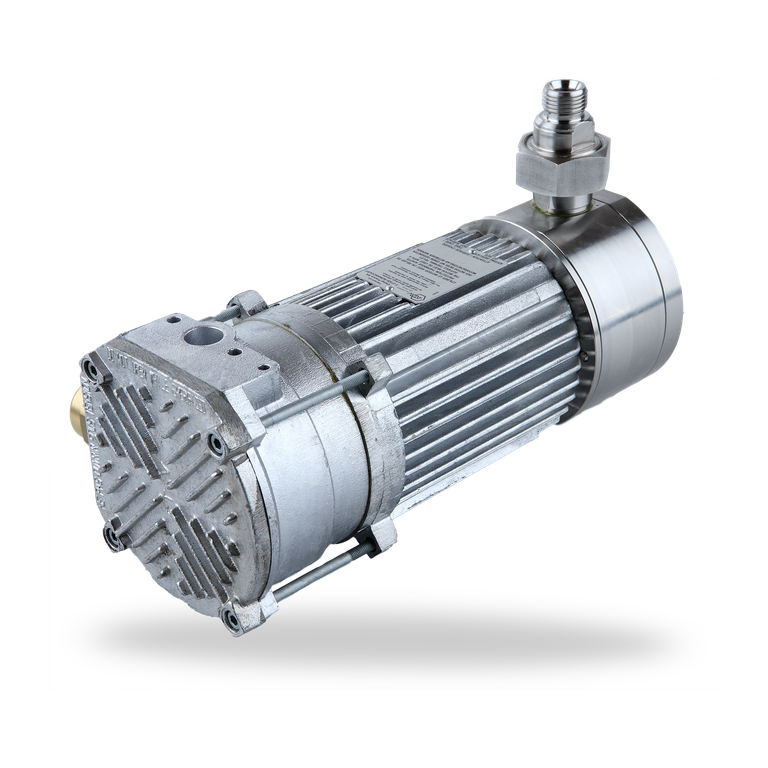

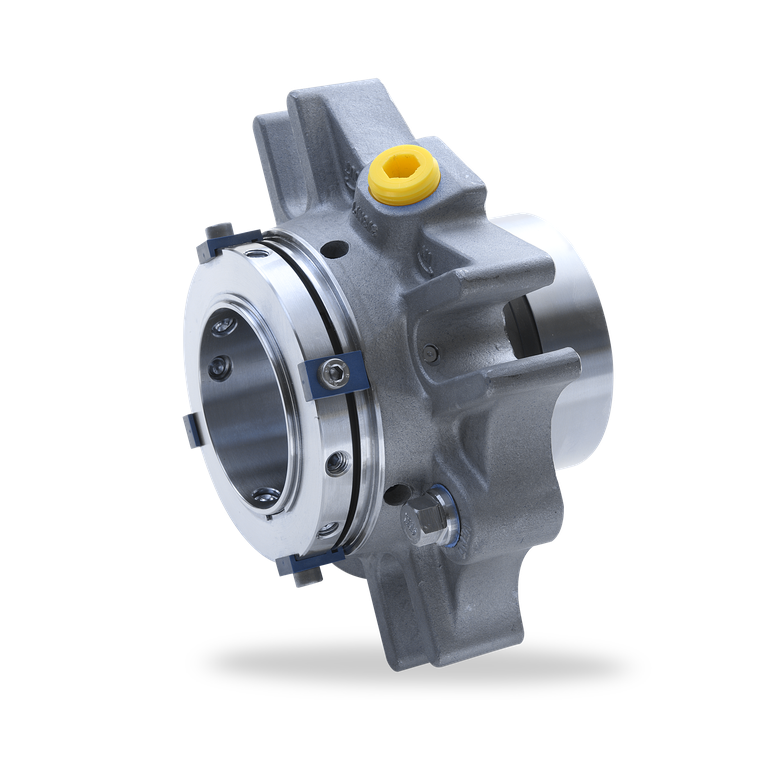

SPU Circulation pumpThe SPU circulating pump (shown: SPU5000) is used for circulating buffer/barrier fluid in seal supply systems (to increase the cooling capacity). The SPU is suitable for water and other liquids of similarly low viscosity. The SPU is available in 5 basic versions:

SPU Circulation pumpThe SPU circulating pump (shown: SPU5000) is used for circulating buffer/barrier fluid in seal supply systems (to increase the cooling capacity). The SPU is suitable for water and other liquids of similarly low viscosity. The SPU is available in 5 basic versions:

SPU1010: without explosion protection

SPU2040: with mechanical seal, with magnetic coupling as an option, ATEX conform

SPU2063: with mechanical seal, with magnetic coupling as an option, ATEX conform

SPU4040: with magnetic coupling, ATEX conform

SPU5000: sealless pump, ATEX conform

ZY Cyclone separatorsThe ZY range (shown: ZY62) is available in three basic versions:

ZY Cyclone separatorsThe ZY range (shown: ZY62) is available in three basic versions:

ZY61: cyclone separator with replaceable insert made of elastomer or ceramic

ZY62: cast version of the cyclone separator

ZY203: cyclone separator for high flow rates and high pressures

Circulation in accordance with API 682 / ISO 21049: Plan 31, Plan 41

SP23 Flow meterFlow meters of the SP23 range are used for checking the amount of fluid used to refill the barrier fluid circuit in closed systems (e.g. SPN1000/3000). The indicated volume equals the amount lost from the circuit through leakage.

SP23 Flow meterFlow meters of the SP23 range are used for checking the amount of fluid used to refill the barrier fluid circuit in closed systems (e.g. SPN1000/3000). The indicated volume equals the amount lost from the circuit through leakage.

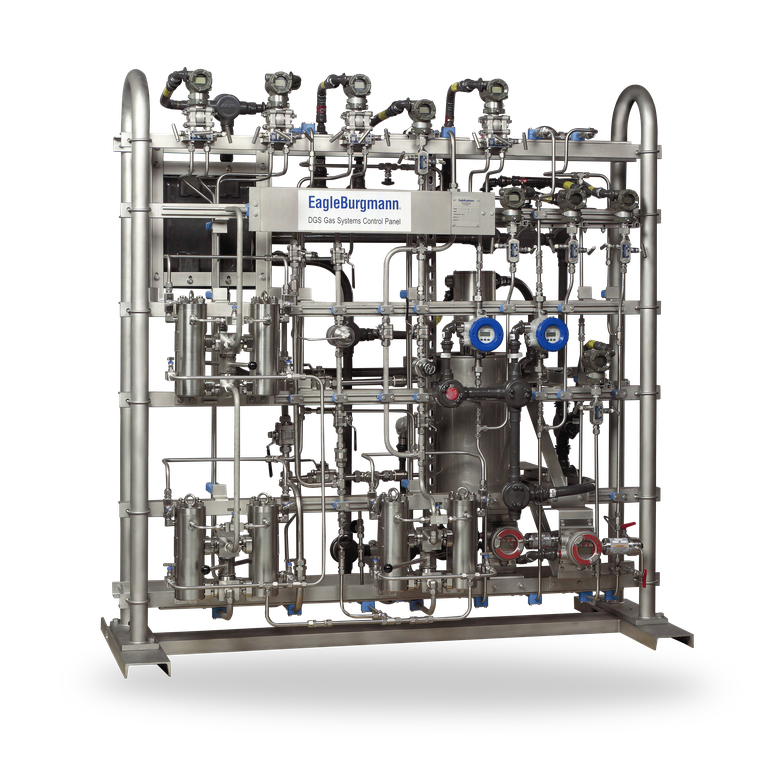

GSS

GSS

Gas supply systemGas supply systems of the GSS range are specially designed for contact-free operated, gas-lubricated mechanical seals. The gas supplied from the supply network (e.g. air or nitrogen) is regulated/monitored by the GSS in accordance with the requirements of the seals being supplied. The GSS systems are equipped with alarm and/or switch-off points depending on specific safety requirements. Centralized monitoring of the measurement values is also possible on request.

Circulation in accordance with API 682 / ISO 21 049: Plan 72, Plan 74

ESPro Supply system for

ESPro Supply system for

electrical submersible pumps

LS050 (Plan 75)The EagleBurgmann leakage control systems of the LS050 range in accordance with API Plan 75 consist of a leakage collection tank with sight-glass and can be equipped with a wide range of measuring instruments.

LS050 (Plan 75)The EagleBurgmann leakage control systems of the LS050 range in accordance with API Plan 75 consist of a leakage collection tank with sight-glass and can be equipped with a wide range of measuring instruments.

Circulation in accordance with API 682 / ISO 21049: Plan 75

BestFlowThe EagleBurgmann BestFlow is a temperature-controlled "money-saving valve" for double seals on which the barrier water connection extends directly into the seal chamber, e.g. Cartex-DN.

BestFlowThe EagleBurgmann BestFlow is a temperature-controlled "money-saving valve" for double seals on which the barrier water connection extends directly into the seal chamber, e.g. Cartex-DN.

HPS Screw pumpScrew pumps of the HPS range are canned pumps. Their ideal area of application is closed high-pressure circuits within hydraulic process engineering systems. Here the HPS represents a genuine, low-price alternative to the centrifugal pump without stuffing box. HPS pumps are not self-priming, so the pump circuit must be well vented.

HPS Screw pumpScrew pumps of the HPS range are canned pumps. Their ideal area of application is closed high-pressure circuits within hydraulic process engineering systems. Here the HPS represents a genuine, low-price alternative to the centrifugal pump without stuffing box. HPS pumps are not self-priming, so the pump circuit must be well vented.

HPS4100: screw pump for a max. permissible operating pressure of 100 bar

HPS4200: screw pump for a max. permissible operating pressure of 200 bar

MAF203 Magnetic filterMagnetic filters of the MAF203 range are inline filters for installation inside pipelines. The combination of magnetic rod and filter element guarantees a high level of efficiency. Magnetic filters are used in seal supply systems and any other such systems in which a liquid has to be cleaned of magnetic and non-magnetic impurities up to a certain size.

MAF203 Magnetic filterMagnetic filters of the MAF203 range are inline filters for installation inside pipelines. The combination of magnetic rod and filter element guarantees a high level of efficiency. Magnetic filters are used in seal supply systems and any other such systems in which a liquid has to be cleaned of magnetic and non-magnetic impurities up to a certain size.

SP23 Pressure gaugeBourdon pressure gauges of the SP23 range are used for visual monitoring of the operating pressure.

SP23 Pressure gaugeBourdon pressure gauges of the SP23 range are used for visual monitoring of the operating pressure.

SMS Seal ManagementThe EagleBurgmann SMS is a customizable system based on four modules. It is used to continuously supply and monitor gas-lubricated mechanical seals.

SMS Seal ManagementThe EagleBurgmann SMS is a customizable system based on four modules. It is used to continuously supply and monitor gas-lubricated mechanical seals.

SP23 (Plan 76)The EagleBurgmann leakage control systems of the SP23 range in accordance with API Plan 76 consist of an orifice, valves and instruments for pressure monitoring.

SP23 (Plan 76)The EagleBurgmann leakage control systems of the SP23 range in accordance with API Plan 76 consist of an orifice, valves and instruments for pressure monitoring.

Circulation in accordance with API 682 / ISO 21049: Plan 76

MAF2001 Magnetic filterMagnetic filters of the MAF2001 range are inline filters for installation inside pipelines. The combination of magnetic rod and filter element guarantees a high level of efficiency. Magnetic filters are used in seal supply systems and any other such systems in which a liquid has to be cleaned of magnetic and non-magnetic impurities up to a certain size.

MAF2001 Magnetic filterMagnetic filters of the MAF2001 range are inline filters for installation inside pipelines. The combination of magnetic rod and filter element guarantees a high level of efficiency. Magnetic filters are used in seal supply systems and any other such systems in which a liquid has to be cleaned of magnetic and non-magnetic impurities up to a certain size.

SP23 Temperature gaugeThe bi-metallic thermometers of the SP23 range are used for visual monitoring of the operating temperature.

SP23 Temperature gaugeThe bi-metallic thermometers of the SP23 range are used for visual monitoring of the operating temperature.

RoTechBooster

RoTechBooster

MAA Magnetic separatorMagnetic separators of the MAA range consist of a pressure casing with integrated magnetic rod. Magnetic separators are used in seal supply systems and any other such systems in which a liquid has to be cleaned of magnetic impurities.

MAA Magnetic separatorMagnetic separators of the MAA range consist of a pressure casing with integrated magnetic rod. Magnetic separators are used in seal supply systems and any other such systems in which a liquid has to be cleaned of magnetic impurities.

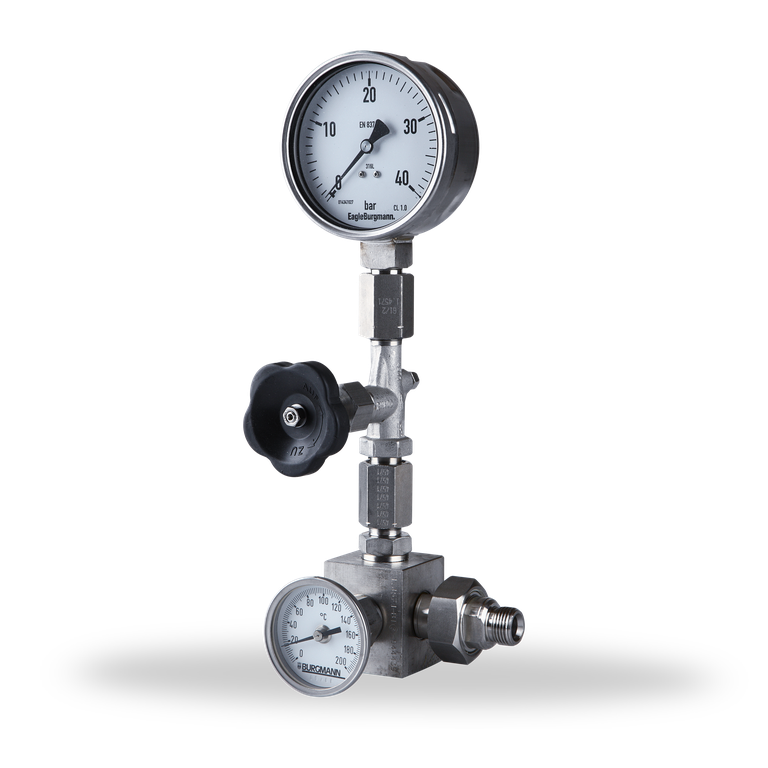

SPI Measuring unitThe measuring unit of the SPI range is used for visual monitoring of the operating temperature and the operating pressure. The measuring unit consists of a pressure gauge (NG 100) with a gauge shut-off valve in accordance with DIN 16270, a bi-metallic thermometer with protective sleeve, and a connector. The SPI is suitable for deployment with the TS2000, TS4000, TS5000 and DRU2063.

SPI Measuring unitThe measuring unit of the SPI range is used for visual monitoring of the operating temperature and the operating pressure. The measuring unit consists of a pressure gauge (NG 100) with a gauge shut-off valve in accordance with DIN 16270, a bi-metallic thermometer with protective sleeve, and a connector. The SPI is suitable for deployment with the TS2000, TS4000, TS5000 and DRU2063.

SPL Level indicatorThe tank-top mounted level indicators of the SPL range are used for continuous measuring, indication and monitoring of fluid levels. The level indicator consists of a vertical pipe with an integrated floating ball and a magnet system. The indicator strip can be positioned through 360° and is fixed to the outside of the vertical pipe.

SPL Level indicatorThe tank-top mounted level indicators of the SPL range are used for continuous measuring, indication and monitoring of fluid levels. The level indicator consists of a vertical pipe with an integrated floating ball and a magnet system. The indicator strip can be positioned through 360° and is fixed to the outside of the vertical pipe.

SPS Level switchLevel switches of the SPS range are used for monitoring and/or controlling fluid levels in vessels, with alarm and/or control of automatic refill units. The SPS is suitable for deployment with the TS1016/A007, TS2000, TS4000 and TS5000 range.

SPS Level switchLevel switches of the SPS range are used for monitoring and/or controlling fluid levels in vessels, with alarm and/or control of automatic refill units. The SPS is suitable for deployment with the TS1016/A007, TS2000, TS4000 and TS5000 range.

SPK Contact unitThe contact unit of the SPK range is used for fluid level monitoring through zero contact magnetic actuation of a contact. The contact unit consists of one or more magnetic elements which transmit the position of the fluid level or of the pressure booster piston rod to the switches without touching. The switches are reed contacts or inductive contacts in accordance with NAMUR.

SPK Contact unitThe contact unit of the SPK range is used for fluid level monitoring through zero contact magnetic actuation of a contact. The contact unit consists of one or more magnetic elements which transmit the position of the fluid level or of the pressure booster piston rod to the switches without touching. The switches are reed contacts or inductive contacts in accordance with NAMUR.

Industrial sector

Industrial sector Building services industry Cement industry Chemical industry Food and beverage industry Household appliances Metal production and processing Mining industry Oil and gas industry Petrochemical industry Pharmaceutical industry Pool and spa applications Power plant technology Process industry Pulp and paper industry Refining technology Shipbuilding Sugar industry Water and waste water technology

Index

Index AD510 / AD520 AGSR AGSZ AX5 AX25 AX25D AX30 AX40K BT-A2 BT-AR BT-PN Cartex Dual seals Cartex Single seals Cartex ANSI Single seals Cartex ANSI Dual seals Cartex-GSDN CGSH-K CobaSeal CSE CSR DF-(P)DGS6 DiamondFace DF-SA DiamondFace DGS EA100 EA560 EBU800 eCartex Dual seals eCartex Single seals eCartex ANSI Dual seals eCartex ANSI Single seals ED560 EH700 EK700 EM300 eMG eMG1 ERB GSO-DN H3B H7N H10 / H8 H12N H74-D H75VK H75VN HA211 HGH201 HJ92N HR HRC...N HRGS-D HRN HS-D HSH-D HSHLU-D LB500 LP-D LP-S M2N M3N M7N M74-D M461 M481 MA290 / MA390 MBS100 MDGS MF95N MFL65 MFL85N MFLCT MFLWT MG1 MG9 MR-D Mtex Dual seals Mtex Single seals NF941 PDGS Pulace SAF(V) / SAP(V) SeccoMix SH(V) SHF / SHP SHF(V)-D / SHP(V)-D SHPV / SHFV Splitex STD1 TDGS Type 4600 Type 4600 Pneumostop Type 4604 Unitex WRS YE400

Search

M2N

M2N

Cartex

Cartex

Single seals

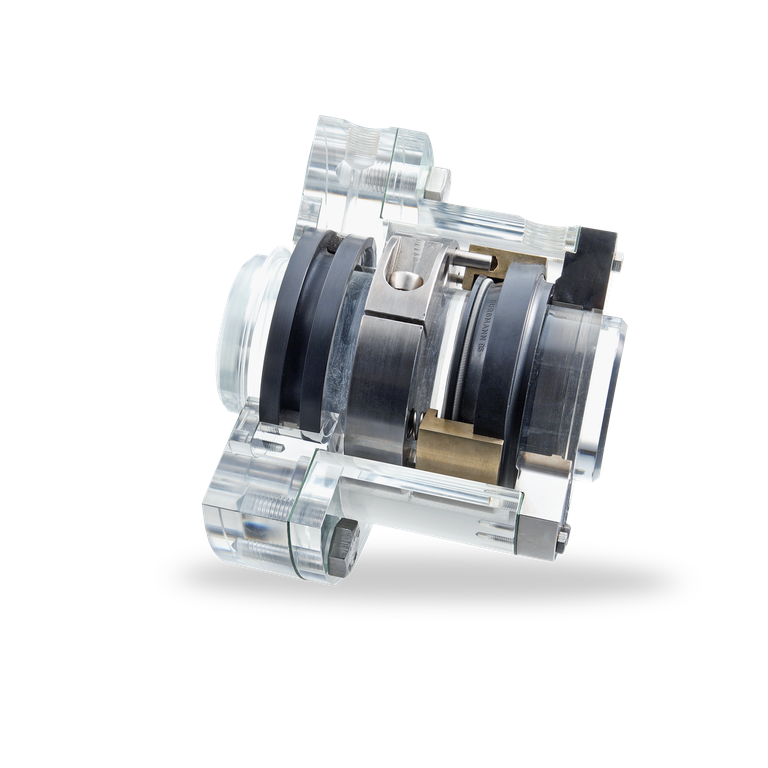

eMG1

eMG1

MBS100

MBS100

HR

HR

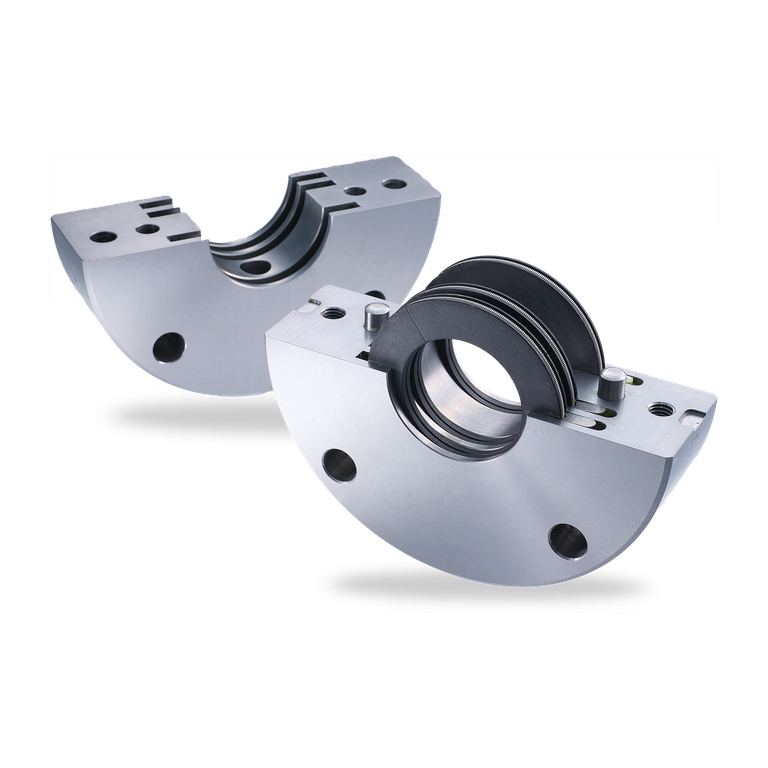

Splitex

Splitex

Cartex-GSDN

Cartex-GSDN

SeccoMix

SeccoMix

AGSZ

AGSZ

ERB

ERB

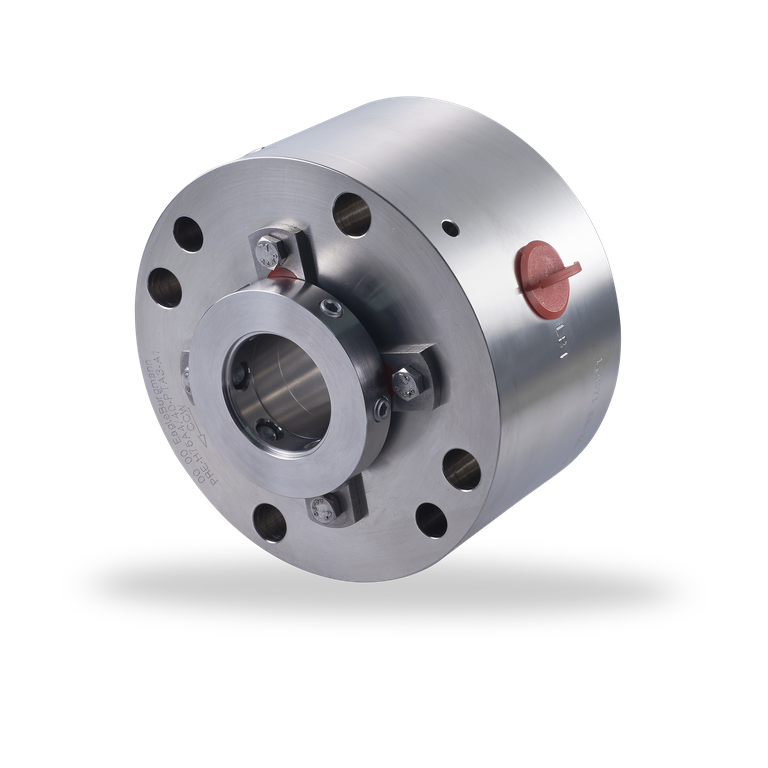

STD1If a STD is employed, it is possible to change seals with the vessel loaded and under pressure (shaft must be stationary!). Installation dimensions according to DIN 28138 Part 1 are possible. Material properties have to be taken into account.

STD1If a STD is employed, it is possible to change seals with the vessel loaded and under pressure (shaft must be stationary!). Installation dimensions according to DIN 28138 Part 1 are possible. Material properties have to be taken into account.

WRS

WRS

CSE

CSE

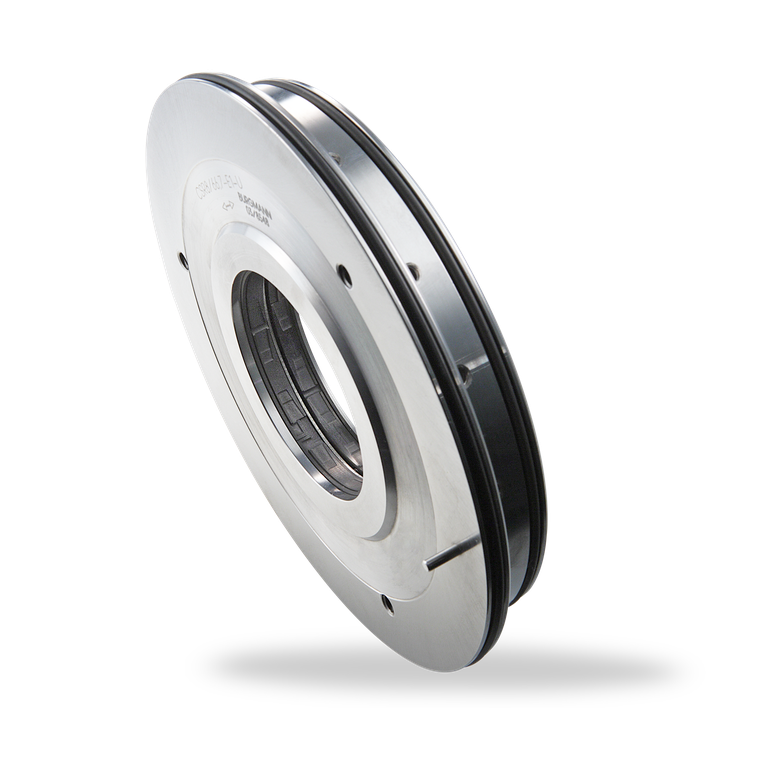

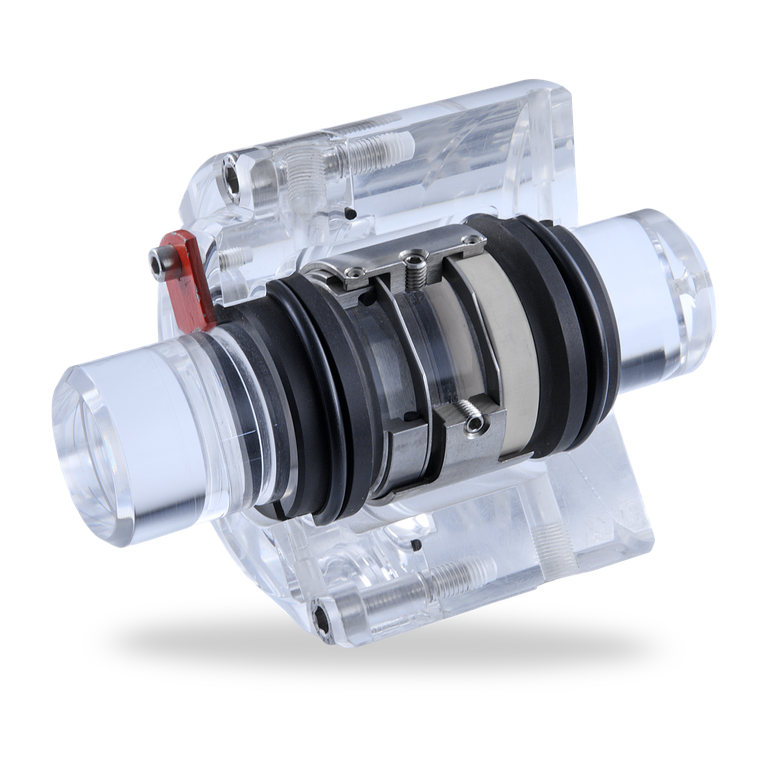

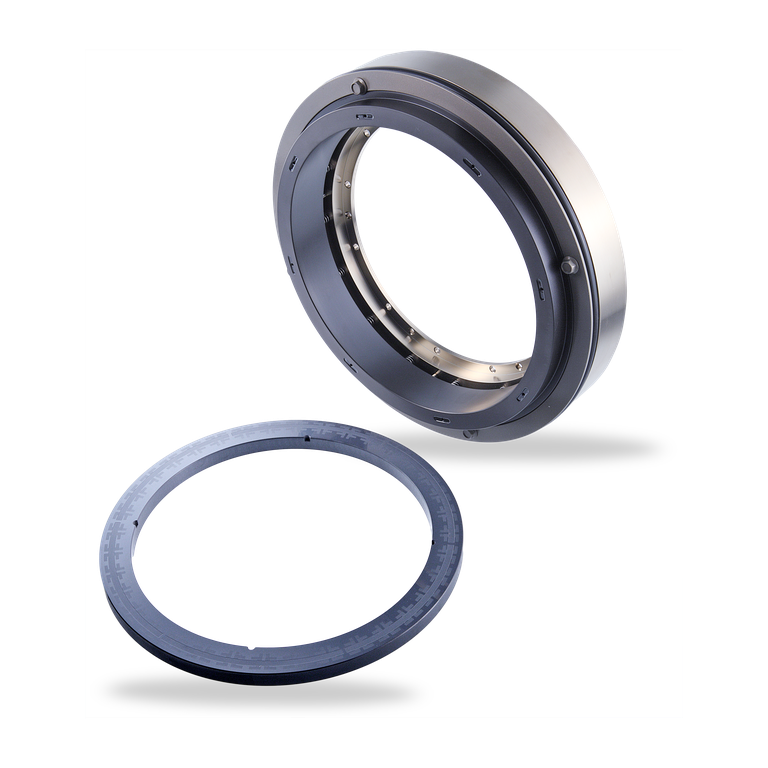

Type 4600The water-lubricated stern tube seals type 4600 from EagleBurgmann are not alone an environment-friendly solution. They meet all technical requirements of modern sealing technology: modular design, convenient installation, little maintenance, no adjustments.

Type 4600The water-lubricated stern tube seals type 4600 from EagleBurgmann are not alone an environment-friendly solution. They meet all technical requirements of modern sealing technology: modular design, convenient installation, little maintenance, no adjustments.

Type 4600 water-lubricated stern tube seals are virtually leak-free and are leaving no oil or grease residues in the waterway. And because they prevent getting water into the bilge, no elaborate actions are required for its disposal.

Please ask us for references.

M3N

M3N

Cartex

Cartex

Dual seals

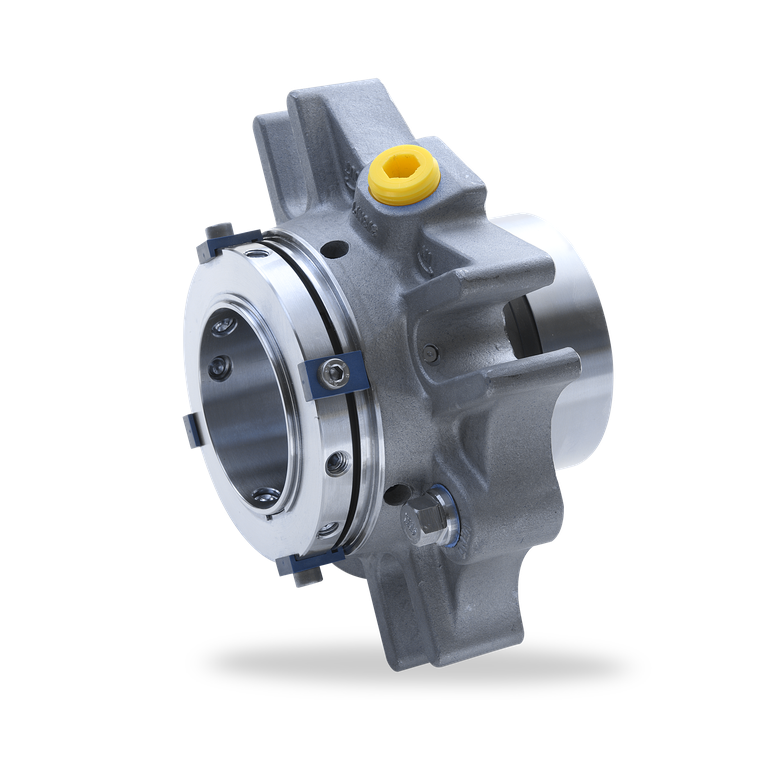

eMG

eMG

MFL85N

MFL85N

HRC...N

HRC...N

HGH201

HGH201

EM300

EM300

AD510 / AD520

AD510 / AD520

AGSR

AGSR

M481

M481

EBU800

EBU800

CSR

CSR

Type 4600 PneumostopThe water-lubricated stern tube seals type 4600 from EagleBurgmann are not alone an environment-friendly solution. They meet all technical requirements of modern sealing technology: modular design, convenient installation, little maintenance, no adjustments. Applying a Pneumostop eliminates costly and time-consuming dry-docking. Maintenance and repairs can be performed with vessel afloat.

Type 4600 PneumostopThe water-lubricated stern tube seals type 4600 from EagleBurgmann are not alone an environment-friendly solution. They meet all technical requirements of modern sealing technology: modular design, convenient installation, little maintenance, no adjustments. Applying a Pneumostop eliminates costly and time-consuming dry-docking. Maintenance and repairs can be performed with vessel afloat.

Type 4600 water-lubricated stern tube seals are virtually leak-free and are leaving no oil or grease residues in the waterway. And because they prevent getting water into the bilge, no elaborate actions are required for its disposal.

Please ask us for references.

M7N

M7N

Cartex ANSI

Cartex ANSI

Single seals

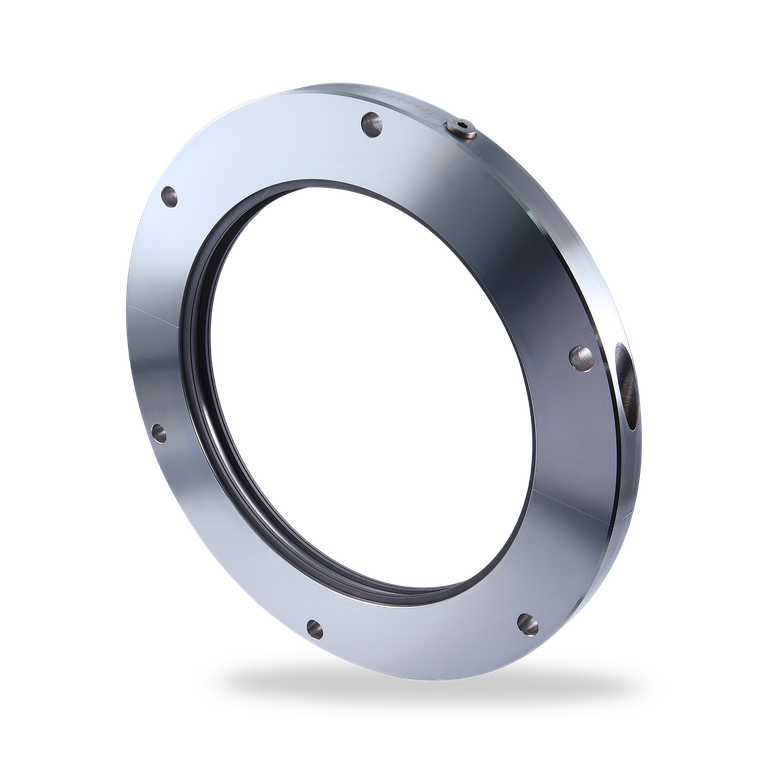

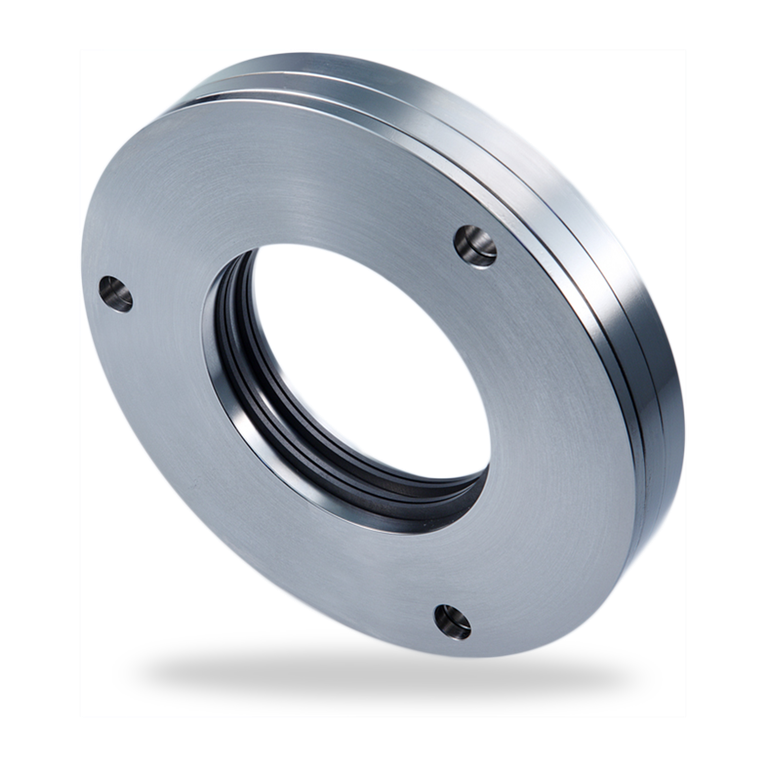

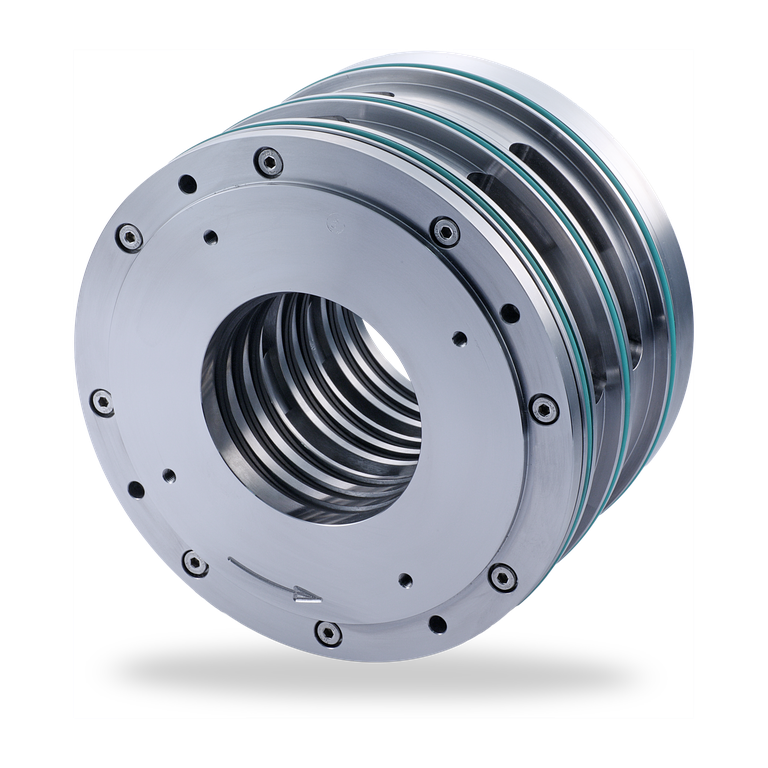

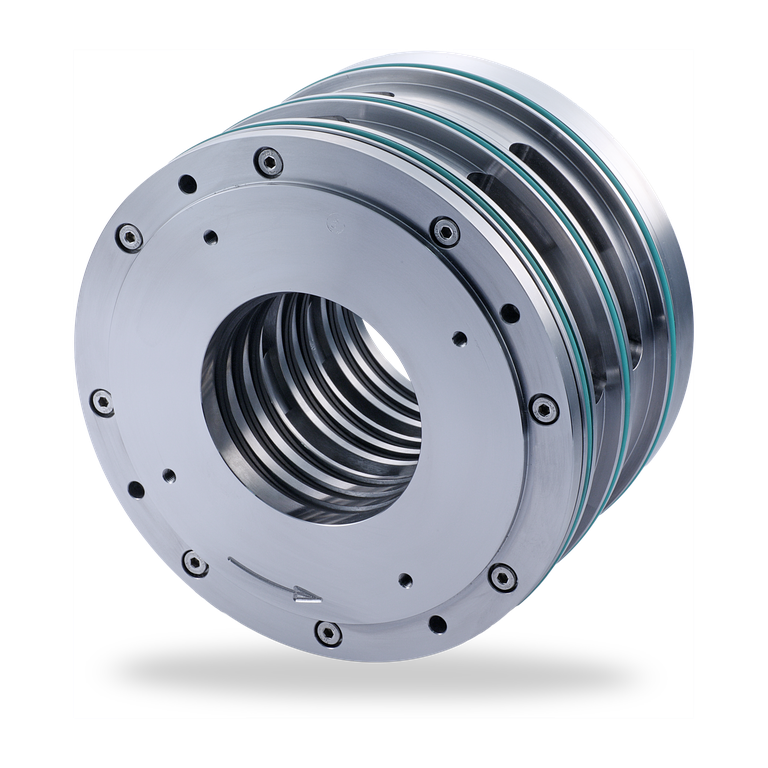

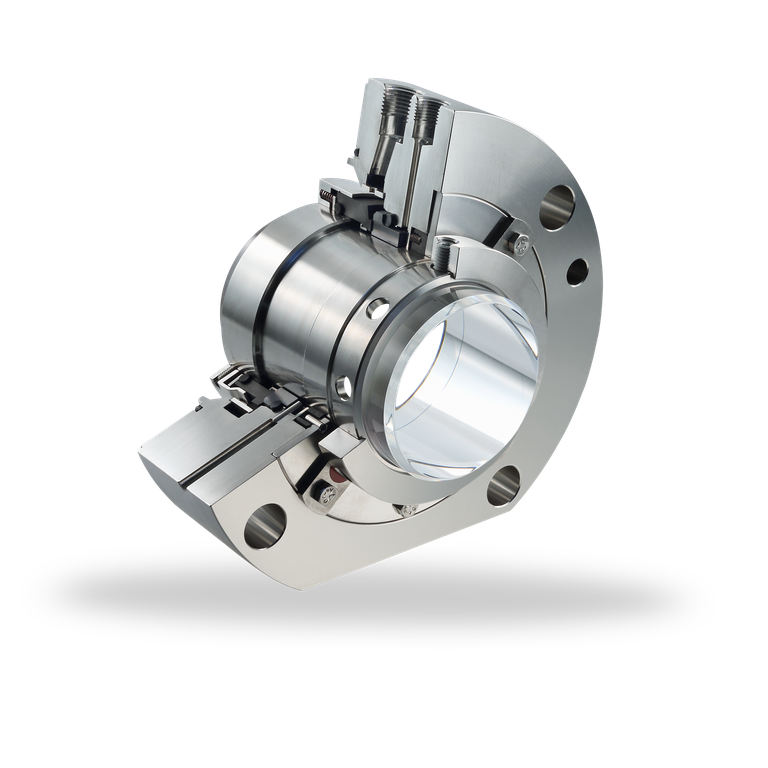

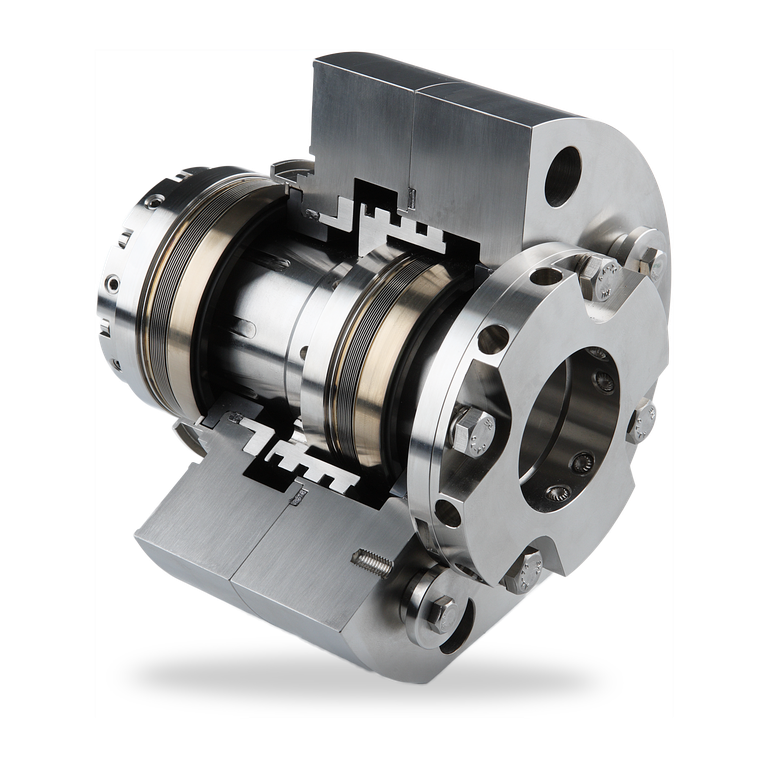

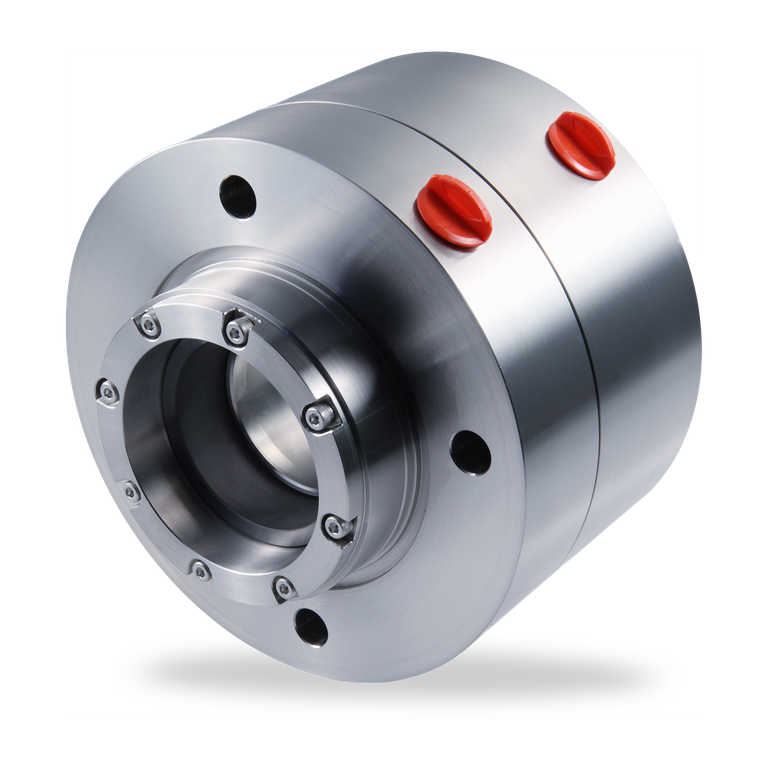

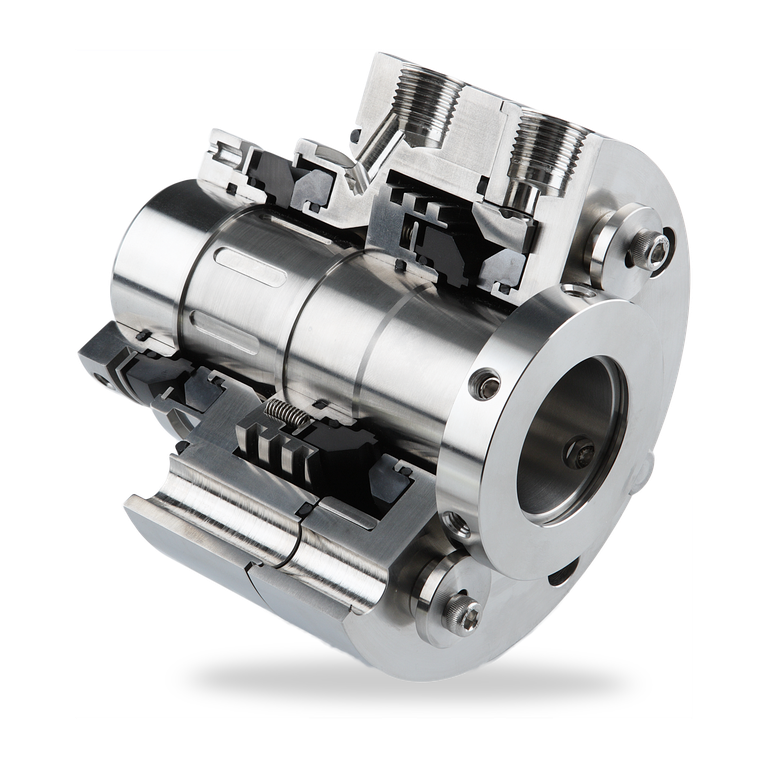

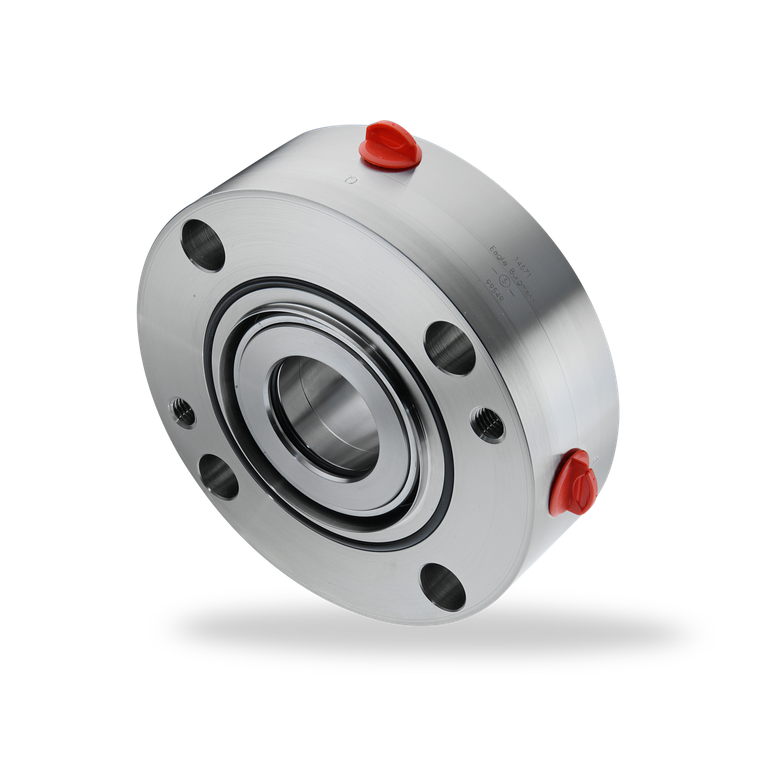

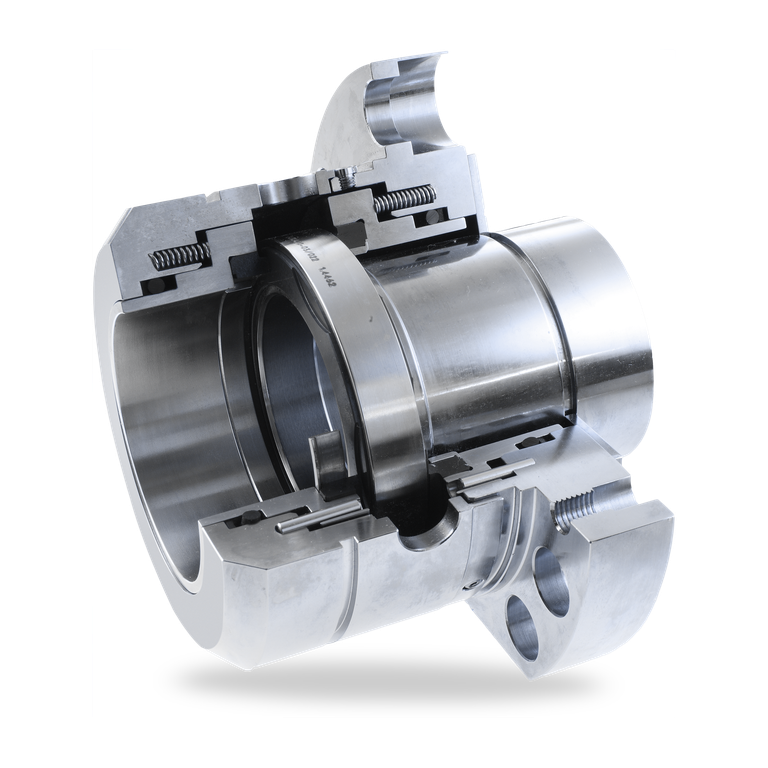

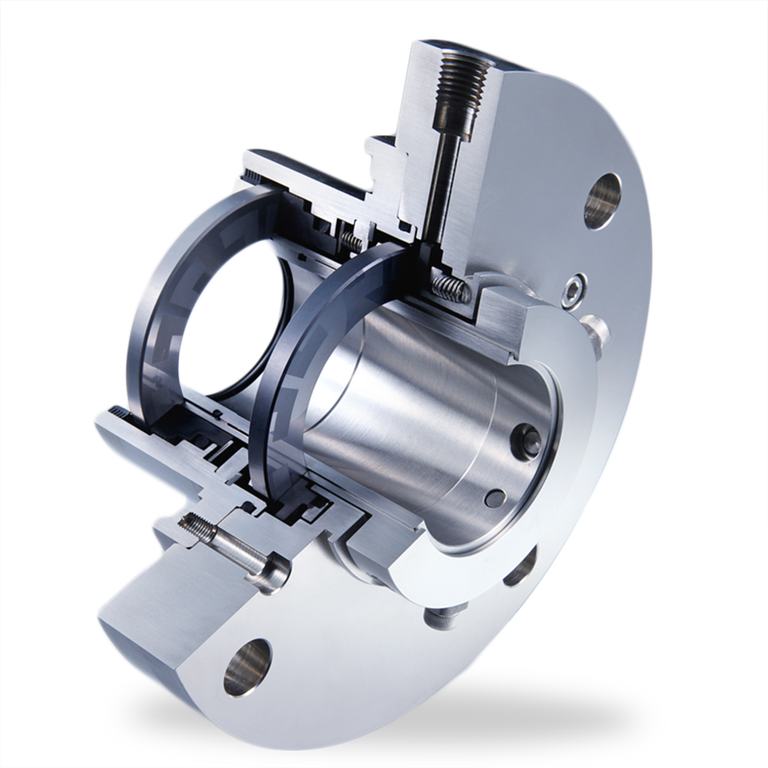

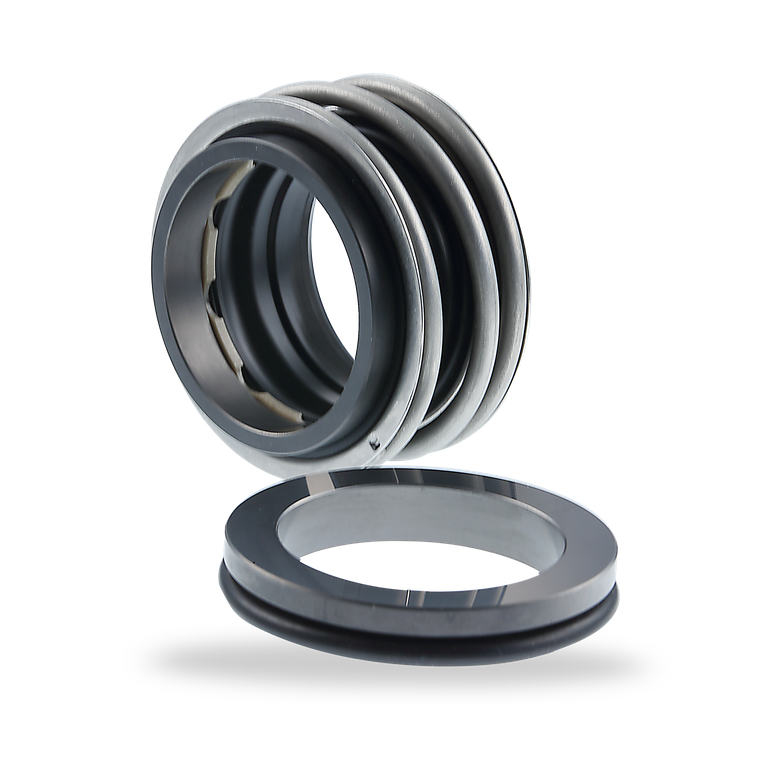

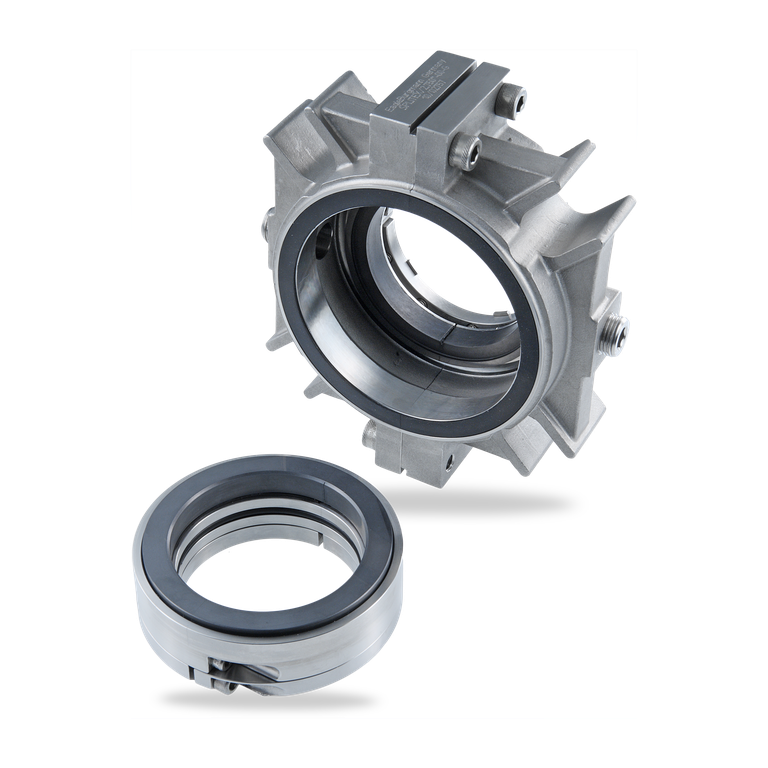

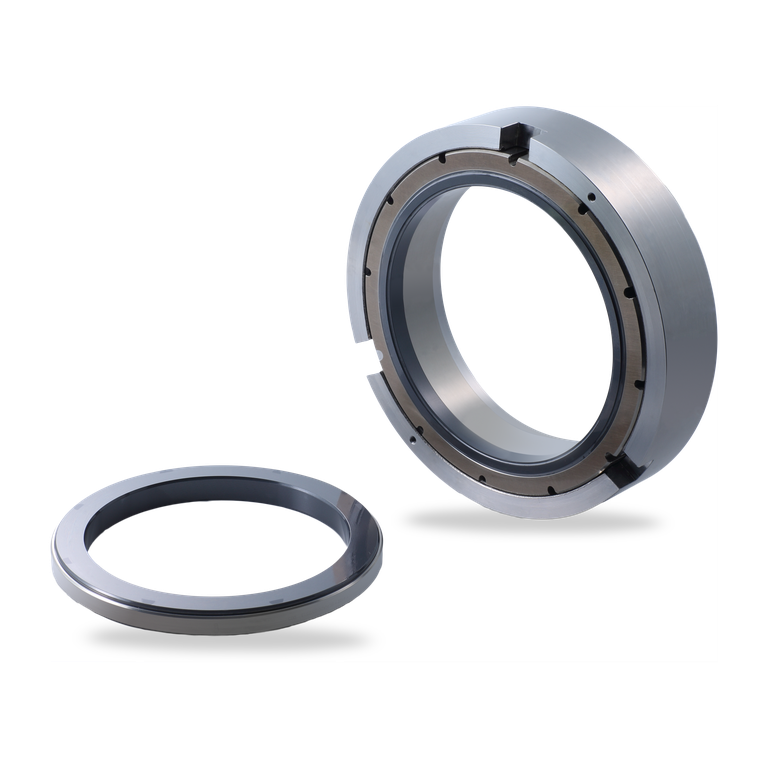

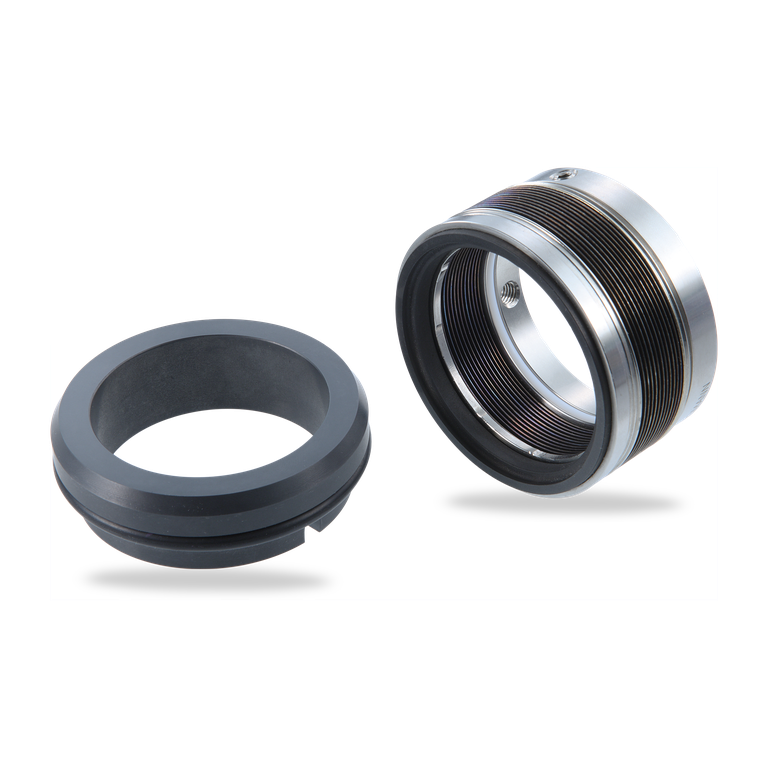

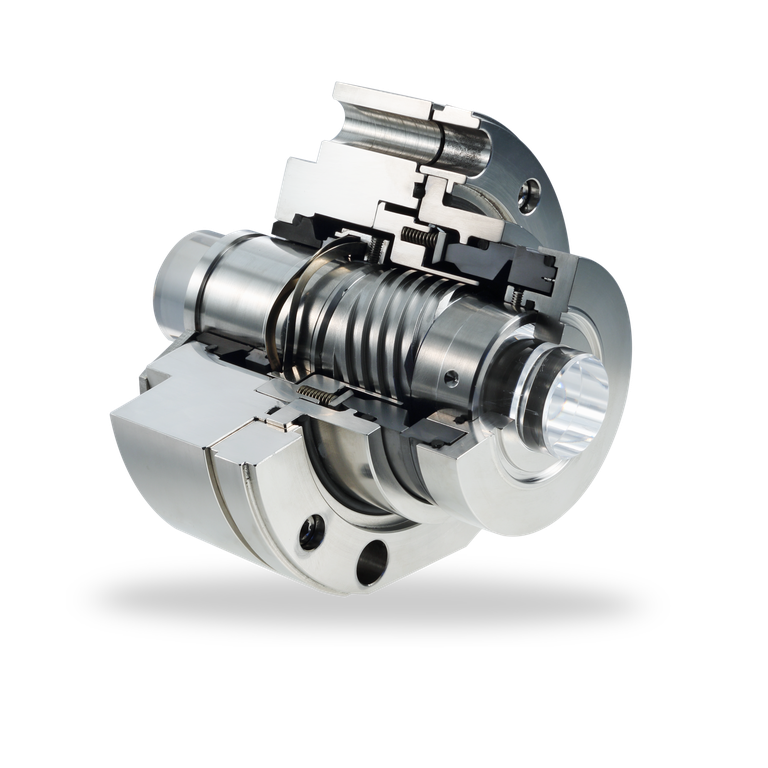

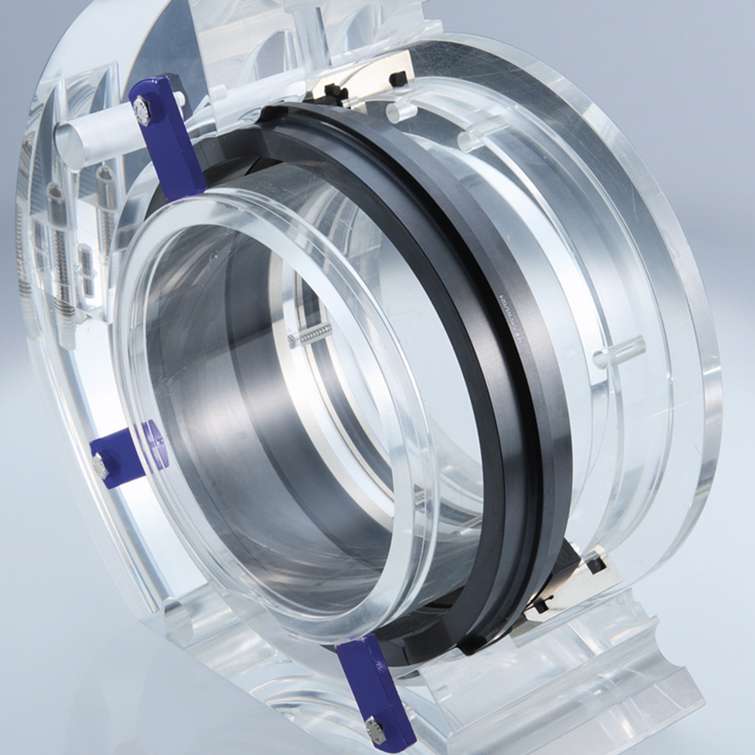

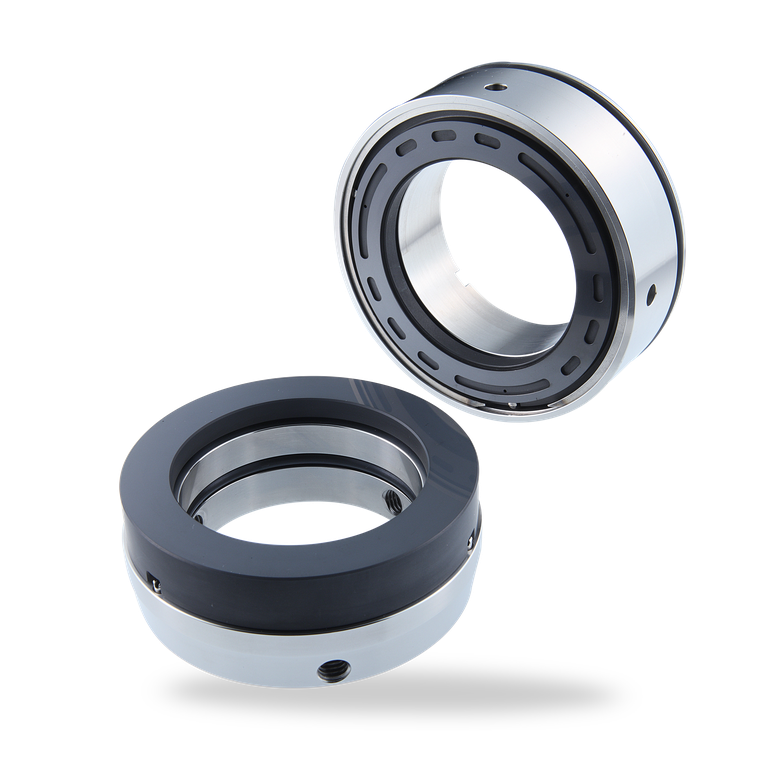

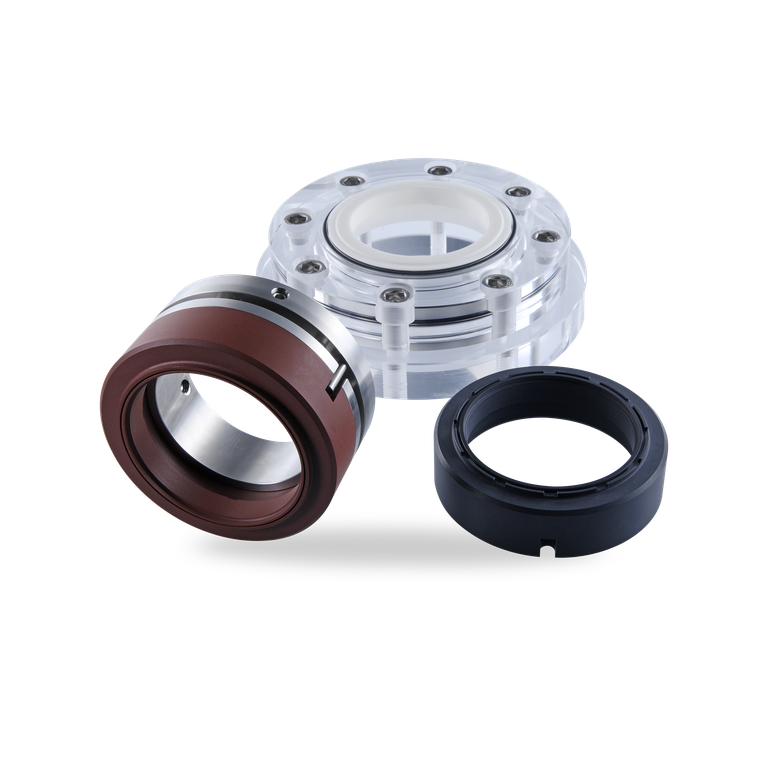

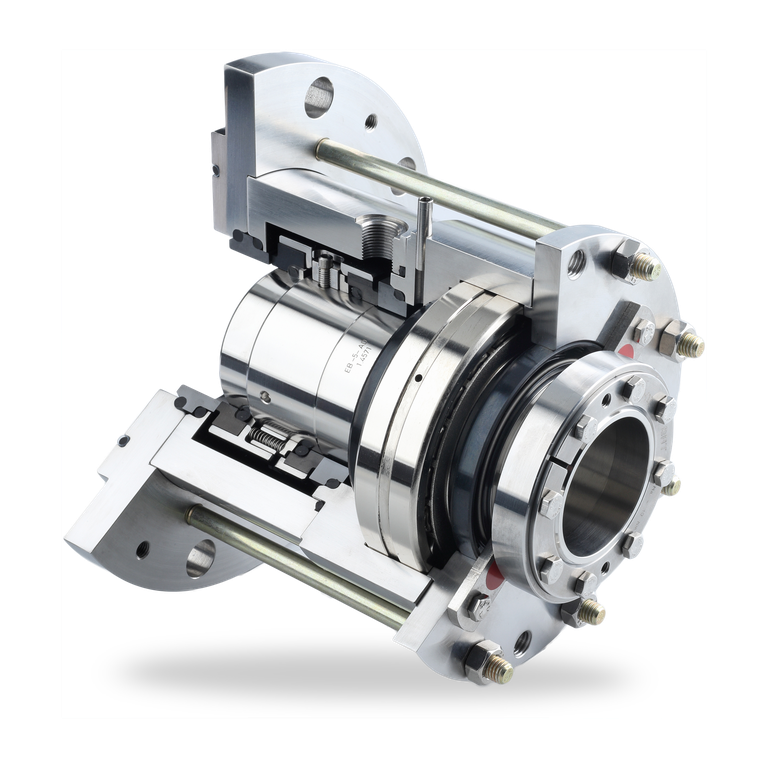

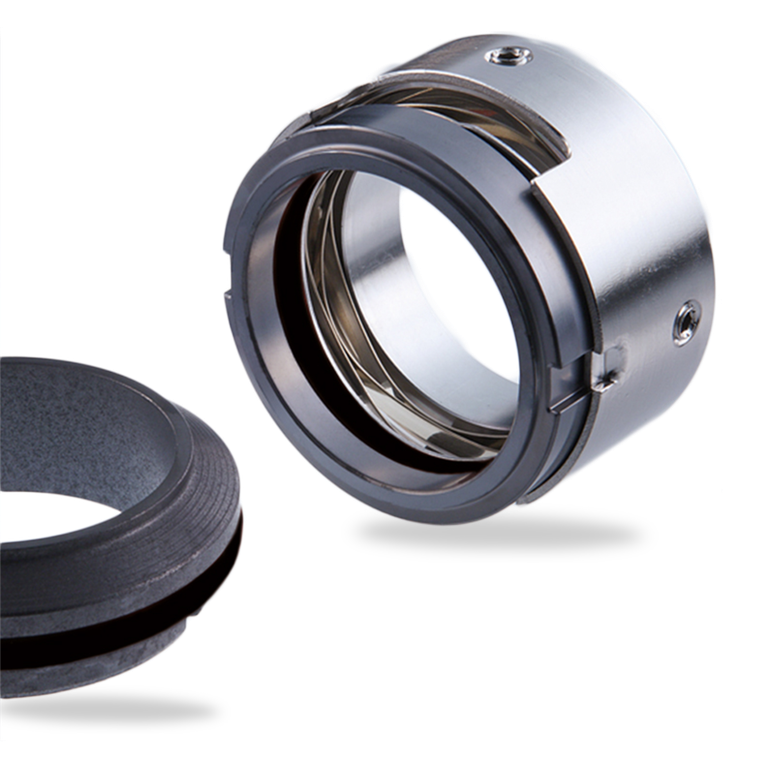

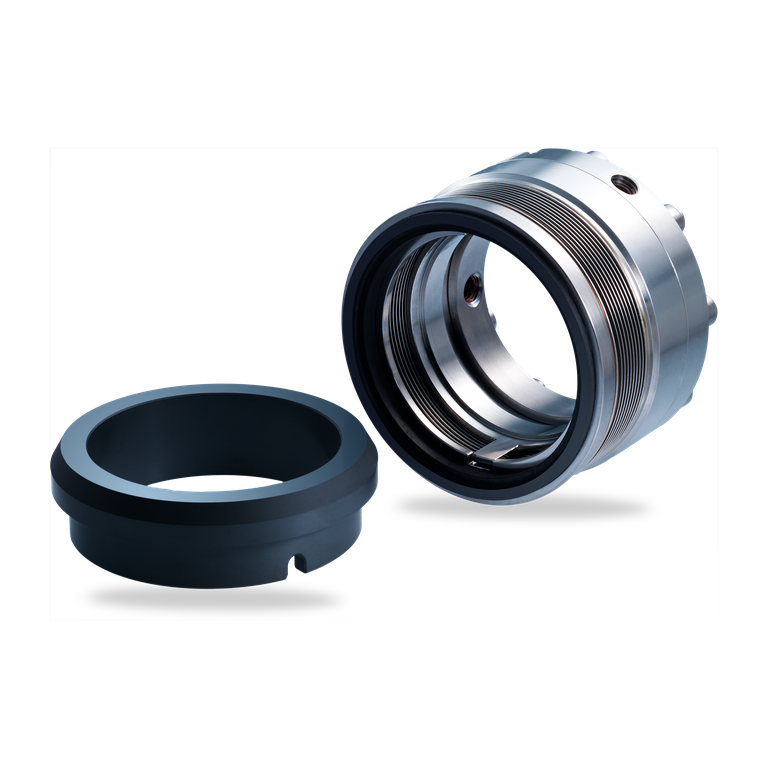

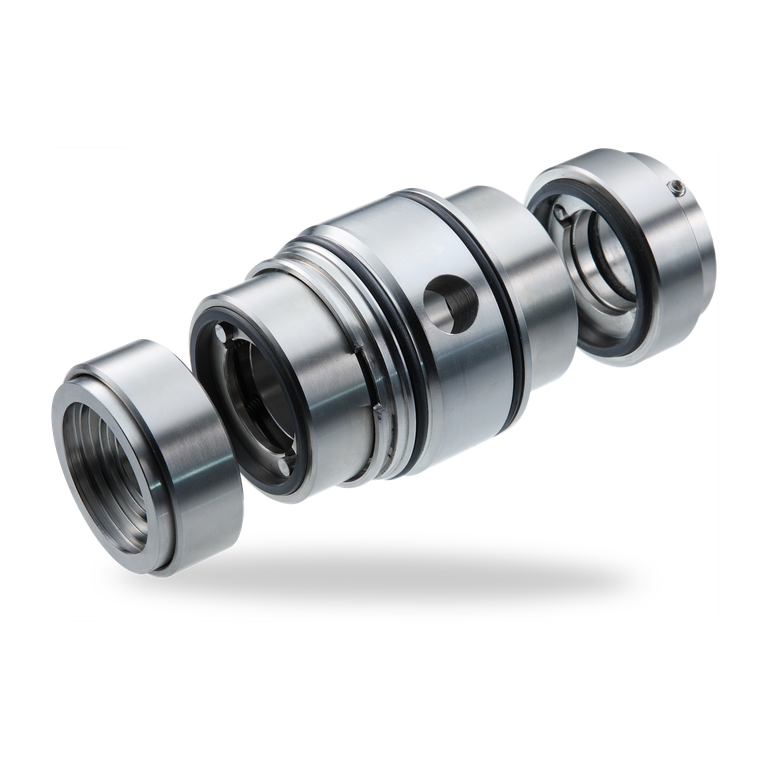

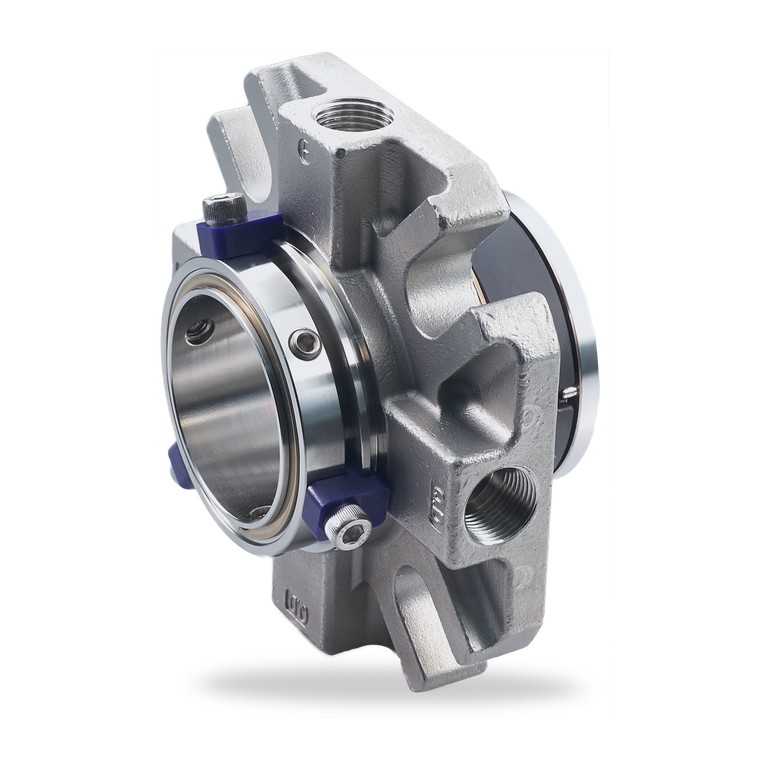

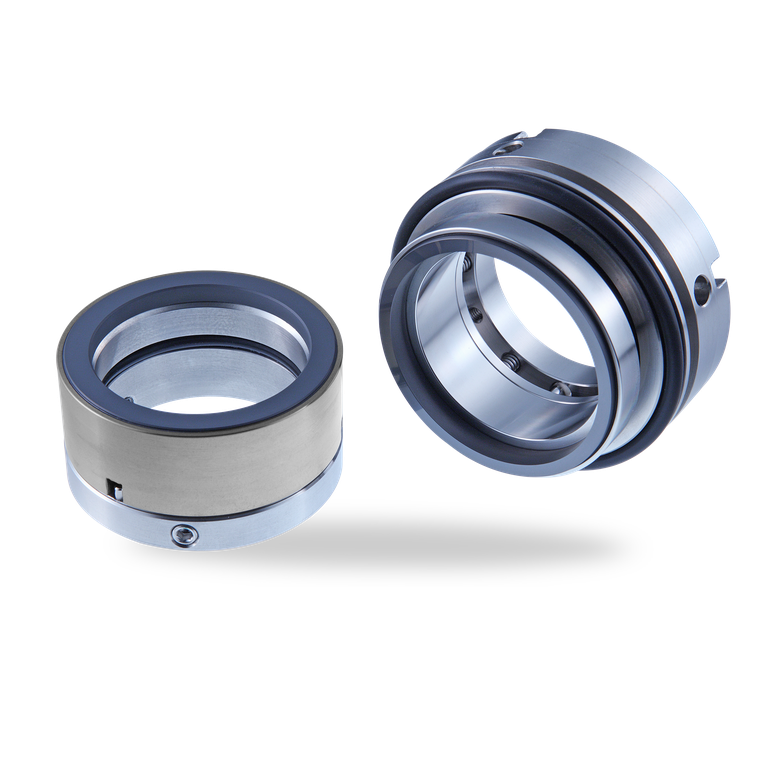

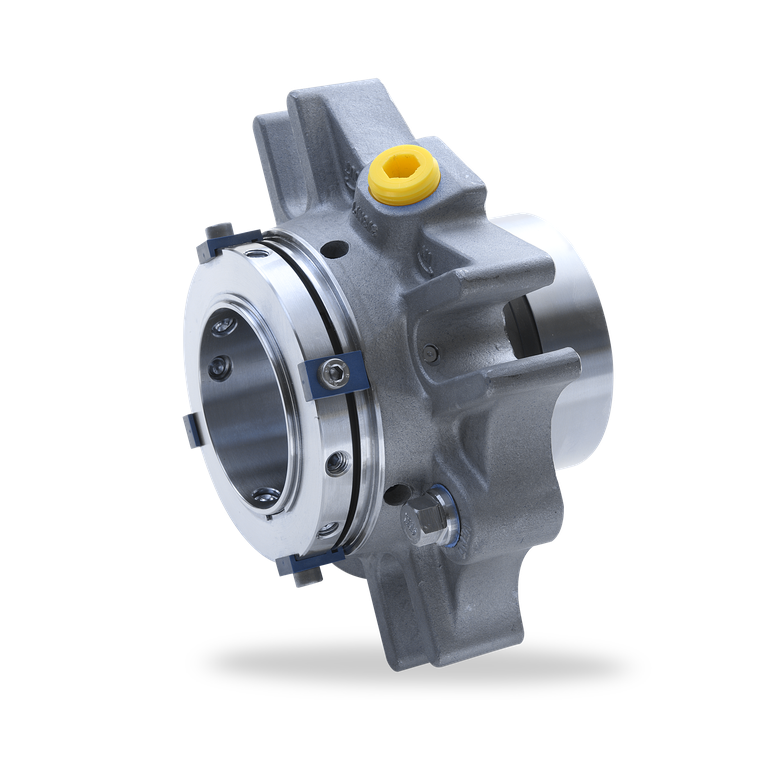

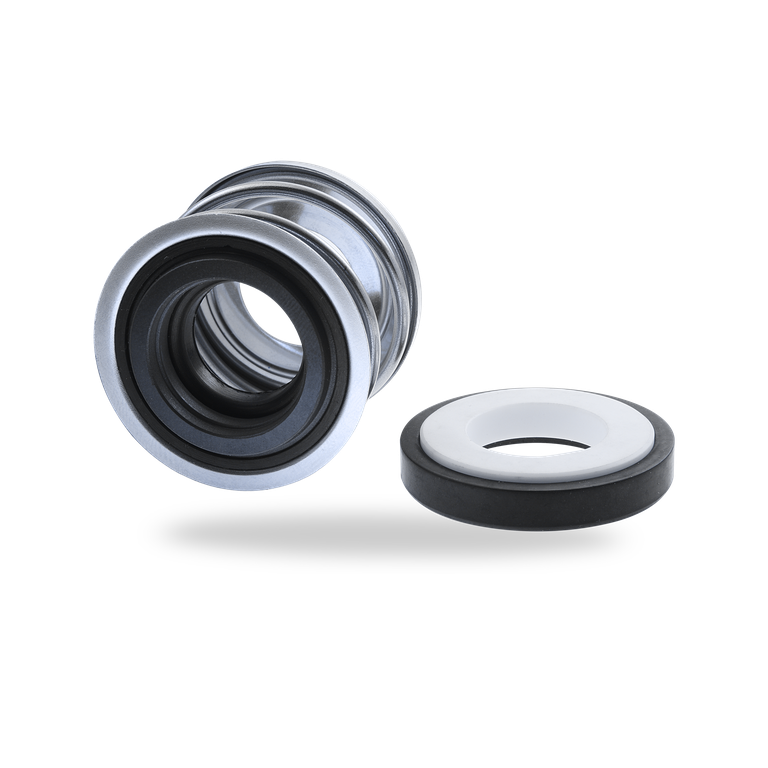

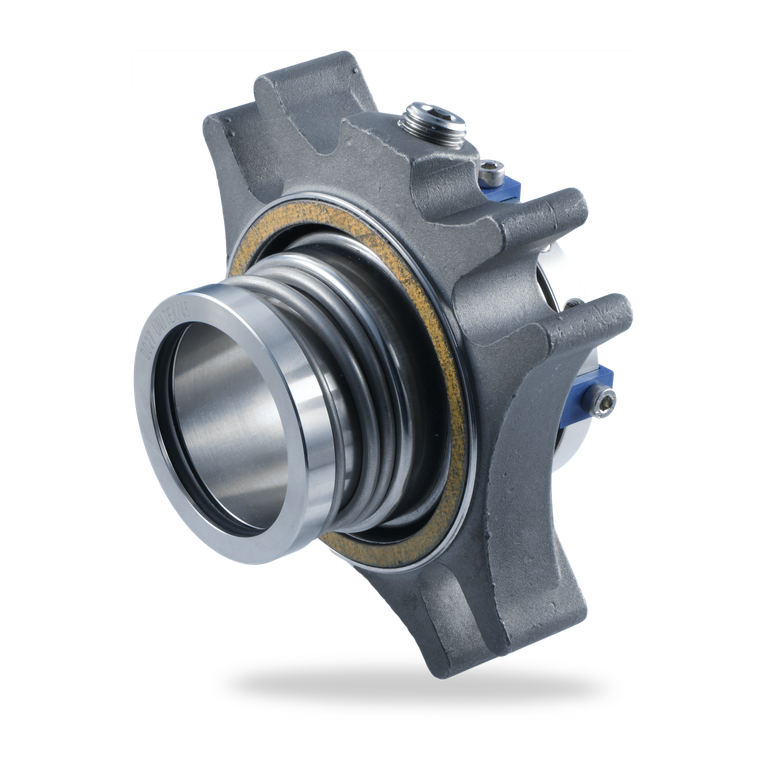

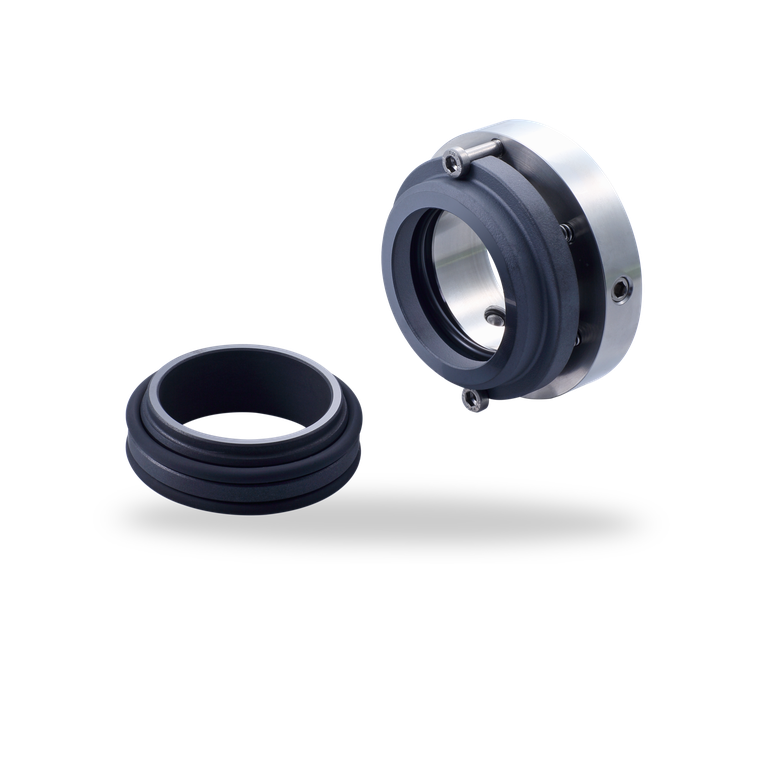

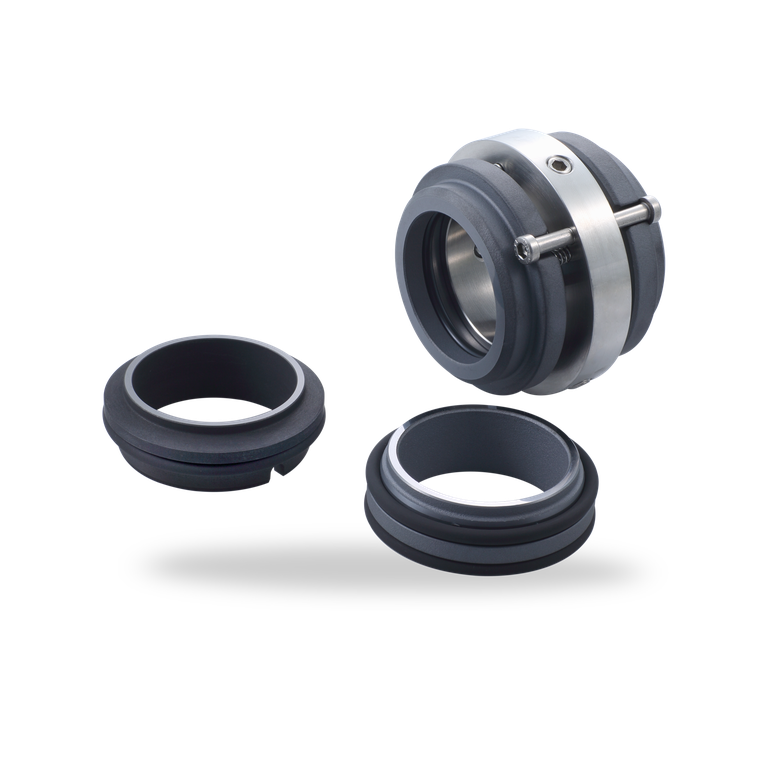

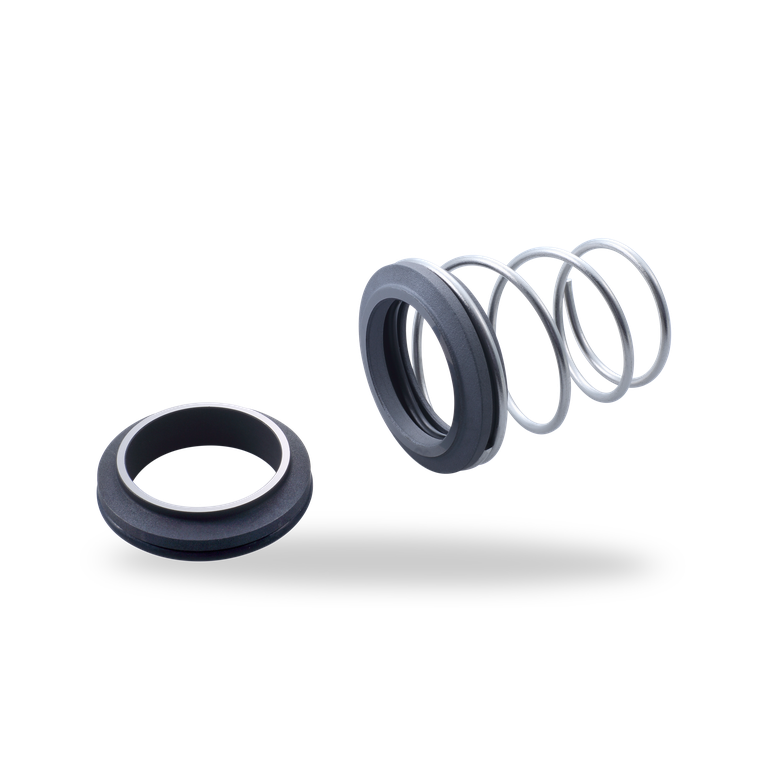

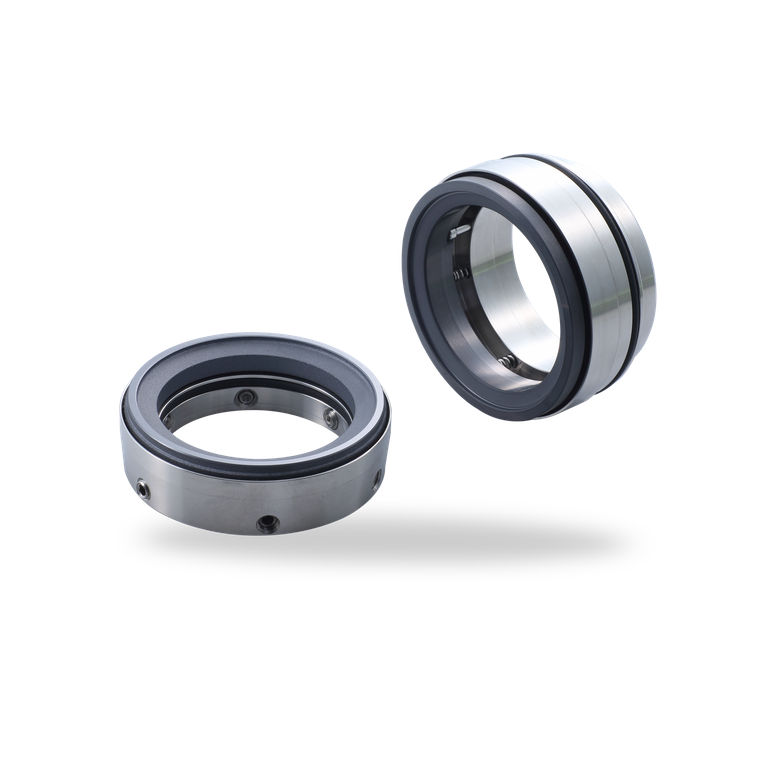

MG1

MG1

MFLWT

MFLWT

LP-D

LP-D

CGSH-K

CGSH-K

M461

M461

MDGS

MDGS

CobaSeal

CobaSeal

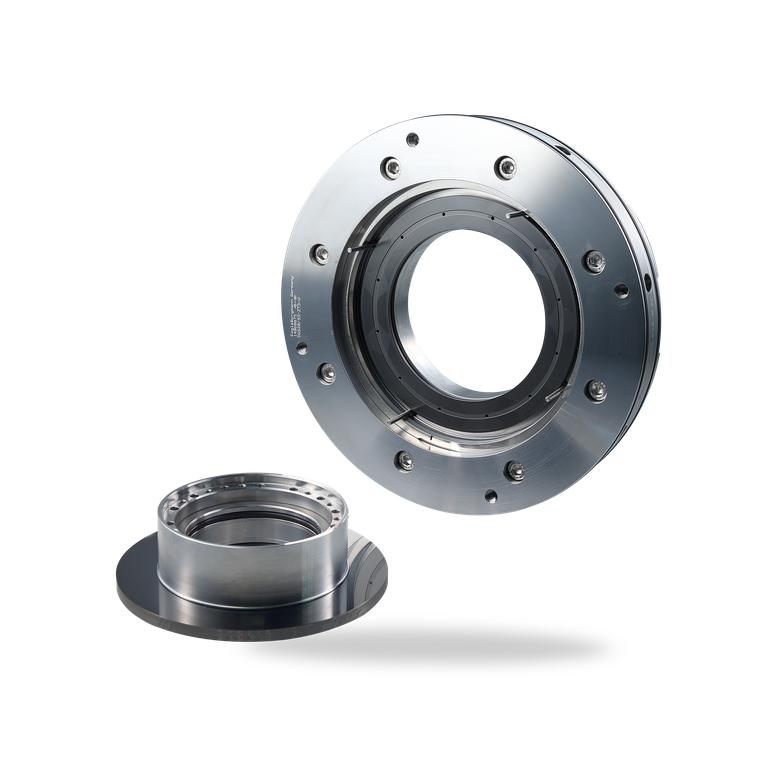

Type 4604The water-lubricated stern tube seals for closed systems Type 4604 from EagleBurgmann are not alone an environment-friendly solution. They meet all technical requirements of modern sealing technology: modular design, convenient installation, little maintenance, no adjustments.

Type 4604The water-lubricated stern tube seals for closed systems Type 4604 from EagleBurgmann are not alone an environment-friendly solution. They meet all technical requirements of modern sealing technology: modular design, convenient installation, little maintenance, no adjustments.

Type 4604 water-lubricated stern tube seals are virtually leak-free and are leaving no oil or grease residues in the waterway. And because they prevent getting water into the bilge, no elaborate actions are required for its disposal. Please ask us for references.

M74-D

M74-D

Cartex ANSI

Cartex ANSI

Dual seals

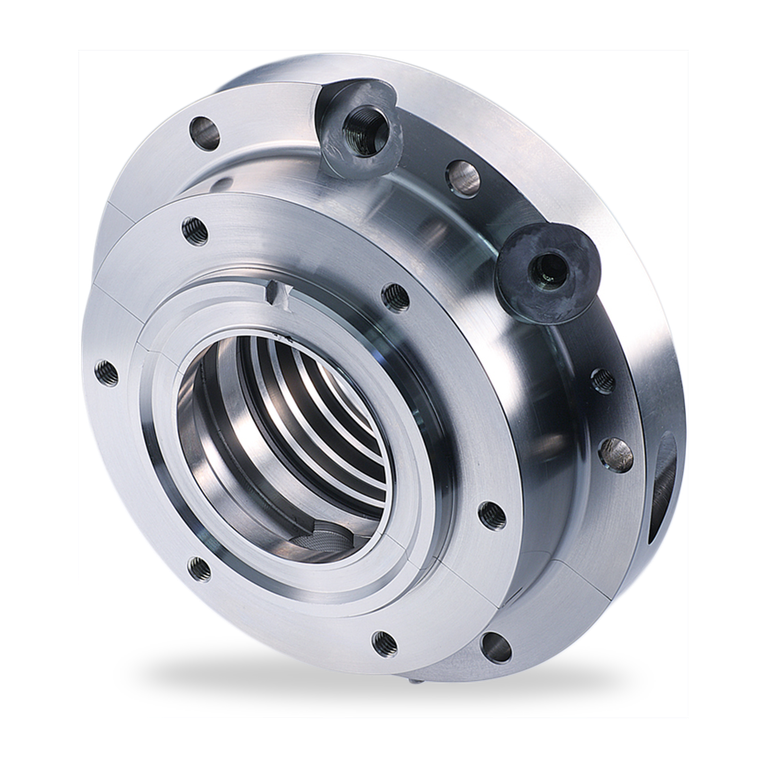

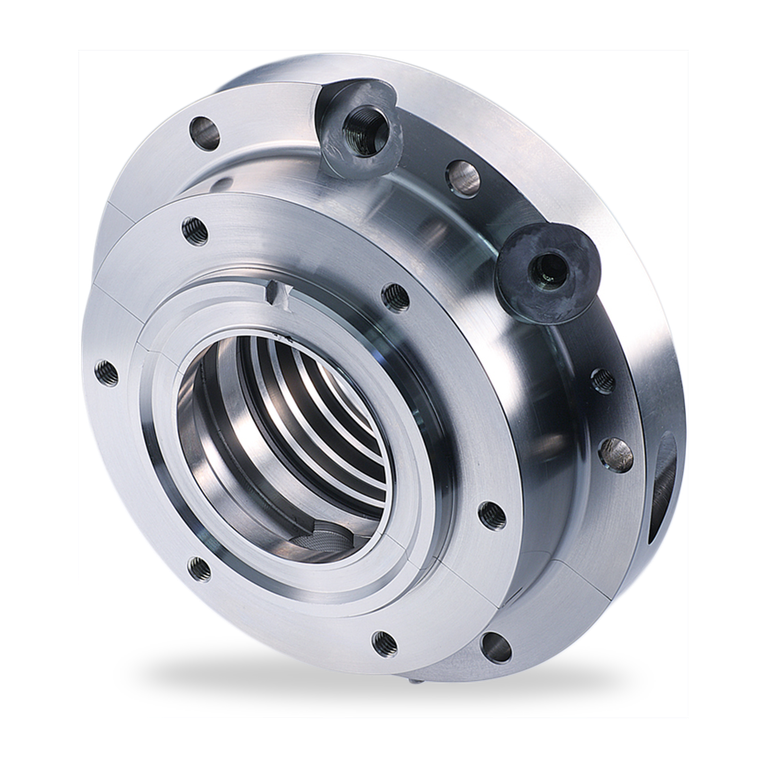

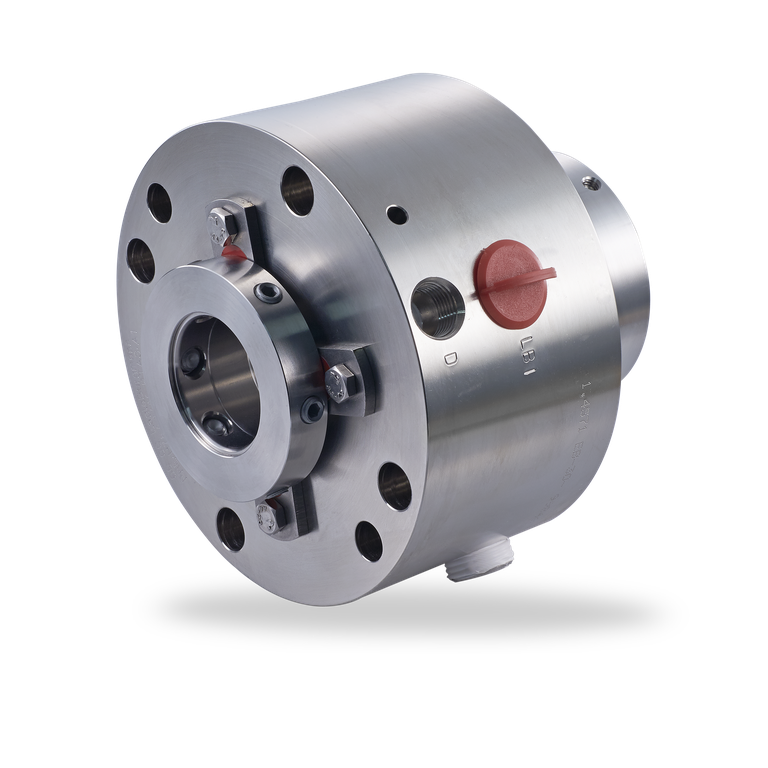

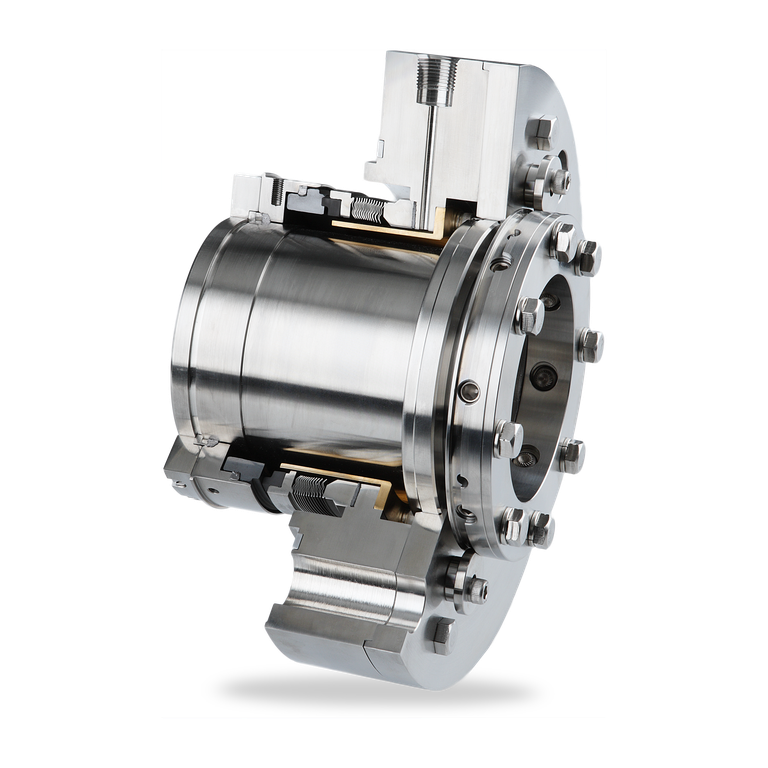

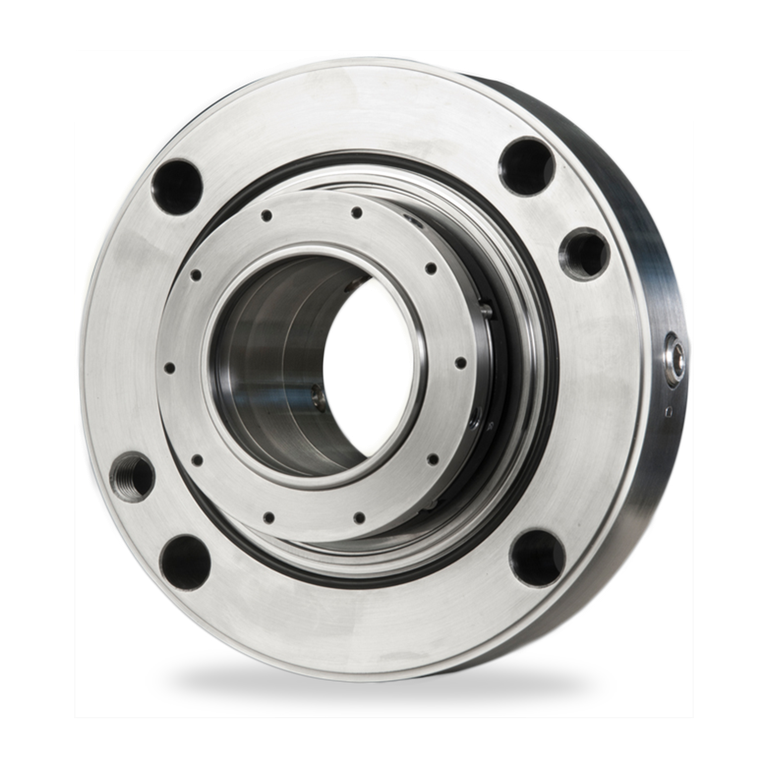

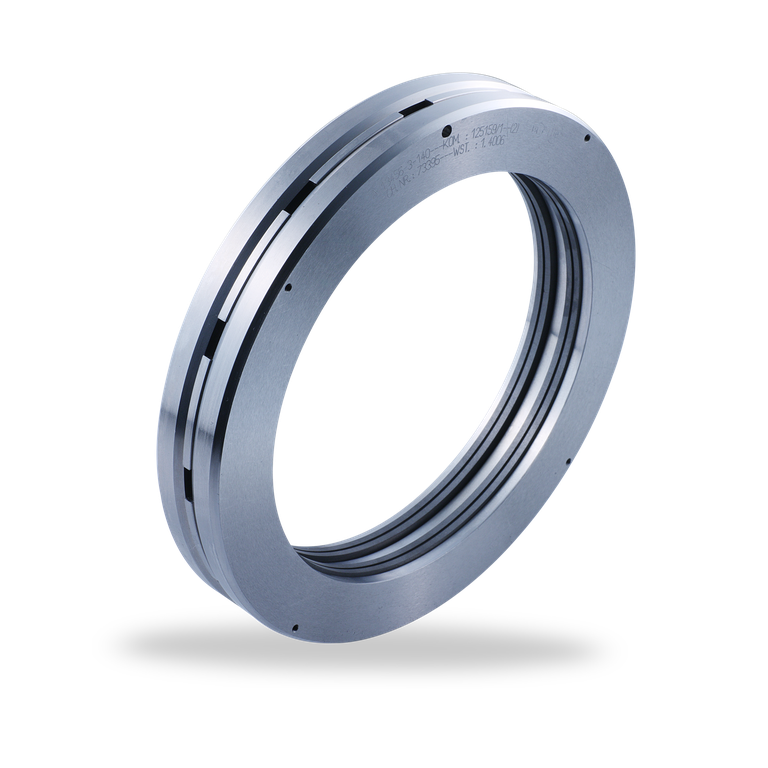

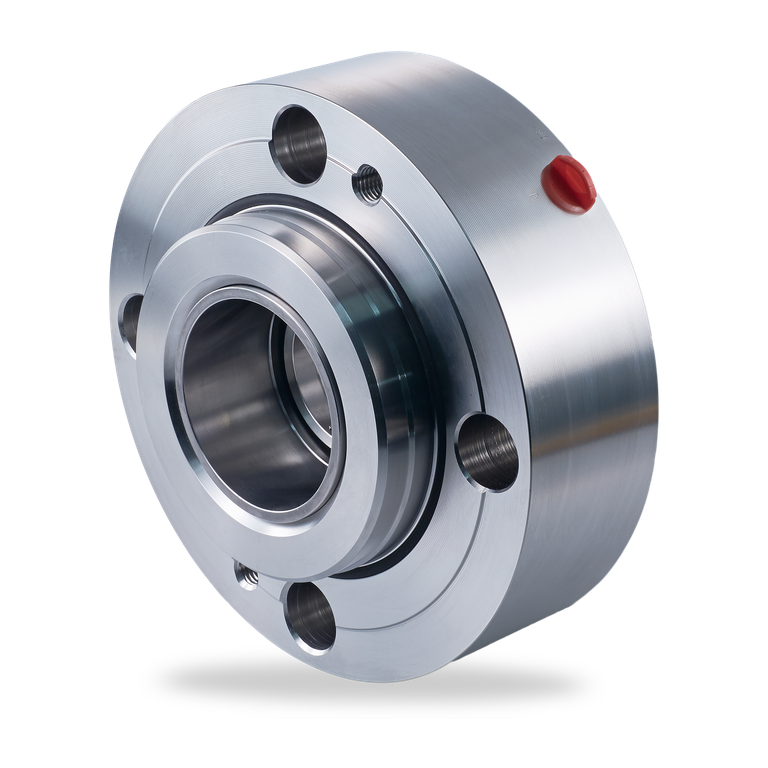

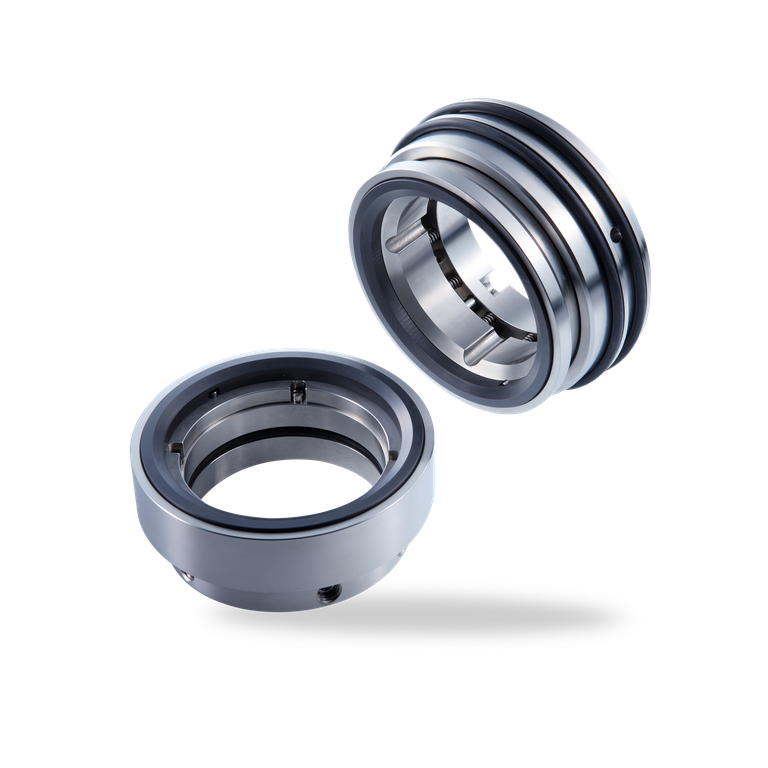

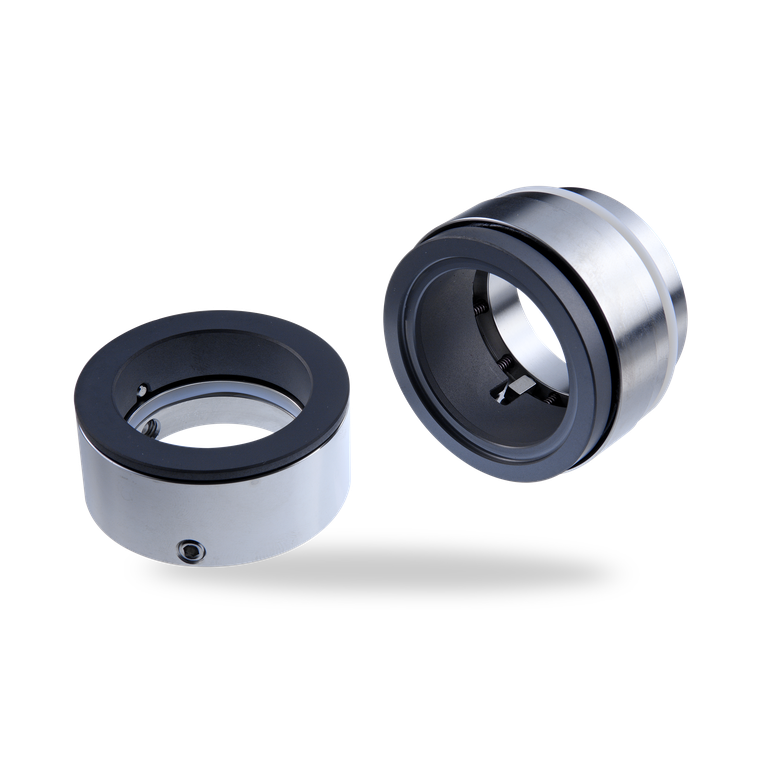

MG9

MG9

MFLCT

MFLCT

LP-S

LP-S

GSO-DN

GSO-DN

MR-D

MR-D

TDGS

TDGS

HA211

HA211

MA290 / MA390

MA290 / MA390

EA560

EA560

MF95N

MF95N

SH(V)

SH(V)

HRGS-D

HRGS-D

HS-D

HS-D

NF941

NF941

H7N

H7N

Mtex Single seals

Mtex Single seals

ED560

ED560

MFL65

MFL65

SHF / SHP

SHF / SHP

HSH-D

HSH-D

LB500

LB500

Mtex Dual seals

Mtex Dual seals

EA100

EA100

YE400

YE400

SHPV / SHFV

SHPV / SHFV

HSHLU-D

HSHLU-D

EK700

EK700

eCartex

eCartex

Single seals

EH700

EH700

SAF(V) / SAP(V)

SAF(V) / SAP(V)

Pulace

Pulace

eCartex

eCartex

Dual seals

BT-AR

BT-AR

SHF(V)-D / SHP(V)-D

SHF(V)-D / SHP(V)-D

HRN

HRN

eCartex ANSI

eCartex ANSI

Single seals

BT-A2

BT-A2

DF-SA DiamondFace

DF-SA DiamondFace

HJ92N

HJ92N

eCartex ANSI

eCartex ANSI

Dual seals

BT-PN

BT-PN

DF-(P)DGS6

DF-(P)DGS6

DiamondFace

H3B

H3B

Unitex

Unitex

AX5

AX5

H12N

H12N

H10 / H8

H10 / H8

H75VN

H75VN

H75VK

H75VK

H74-D

H74-D

AX25

AX25

AX25D

AX25D

AX30

AX30

AX40K

AX40K

请输入账号

请输入密码

请输验证码

以上信息由企业自行提供,信息内容的真实性、准确性和合法性由相关企业负责,化工仪器网对此不承担任何保证责任。

温馨提示:为规避购买风险,建议您在购买产品前务必确认供应商资质及产品质量。